The pace of technological change in industries such as automotive and home appliances is reshaping manufacturing priorities. Electric vehicles (EVs) and smart appliances are increasingly becoming the standard, and with them comes the urgent need for effective thermal protection.

According to the International Energy Agency (IEA), approximately 14 million new electric cars were registered worldwide in 2023, with EV sales surpassing the previous year by 3.5 million, a 35% year-over-year increase (Source: https://www.iea.org/).

This surge is intensifying demand for high-performance thermal protectors in electric drivetrains and battery management systems. The role of thermal protectors is therefore expanding beyond safety into a core enabler of innovation in the modern industrial landscape.

How Thermal Protectors Work and Why They’re Important

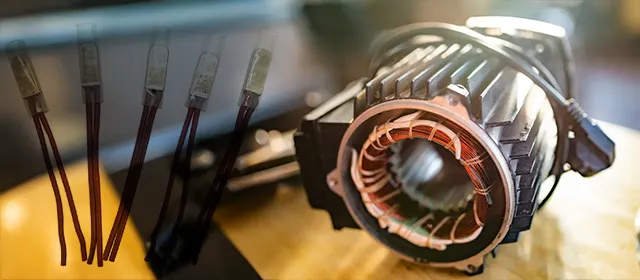

Thermal protectors are devices that detect and respond to temperature changes to prevent overheating and ensure system reliability. They work in critical areas like electric drivetrains where temperature control is key to performance and longevity. In battery management systems, they prevent degradation and mitigate overheating risks. For smart appliances, they ensure safety and efficiency. The technology is evolving fast and they are essential where performance, safety and longevity meet.

What’s Driving the Demand for Thermal Protectors?

The demand for thermal protectors is driven by the growth of electric vehicle and home appliance markets. In the automotive industry, the surge in EV adoption is creating a huge need for thermal protection systems. In the home appliance industry, China’s market size reached 1.84 trillion yuan ($257.6 billion) in 2023, a 7% year-on-year growth, with profits of 156.5 billion yuan, a 12.1% year-on-year growth (Source: https://en.cheaa.org/). The growth is driven by the increasing penetration of appliances and the growing demand for smart technology, both of which rely on thermal management solutions. Together, these trends will continue to drive the demand for advanced thermal protectors.

Key Technological Innovations in Thermal Protectors

Recent advancements in thermal protector technology are transforming how industries approach safety and efficiency. Innovations in materials, such as high-performance alloys and polymers, are enabling protectors to respond more quickly and operate at higher precision. Enhanced design approaches allow thermal protectors to integrate seamlessly into compact systems, improving reliability without compromising performance. These developments are not only enhancing product performance but also opening new opportunities for manufacturers.

- Advanced Materials for Thermal Protection: The U.S. Department of Energy's Vehicle Technologies Office has been actively researching lightweight materials to improve the efficiency and safety of electric vehicles (EVs). Their initiatives focus on developing advanced high-strength steels, aluminum alloys, magnesium alloys, carbon fiber composites, and multi-material systems. These materials aim to reduce vehicle weight by 25% by 2030, which is crucial for enhancing battery performance and overall vehicle efficiency.

- Thermal Management in Electric Vehicles: Effective thermal management is essential for EV battery safety and longevity. The National Renewable Energy Laboratory (NREL) has been at the forefront of developing thermal protection systems for EVs. Their research includes the development of advanced thermal barrier coatings and heat exchanger technologies to maintain optimal battery temperatures, thereby preventing overheating and potential failures.

- Innovations in Thermal Barrier Coatings: The U.S. Department of Energy's Advanced Energy Materials program has been funding projects to develop innovative thermal barrier coatings. For instance, a project led by the University of Maryland focuses on creating hetero-multilayered ceramic coatings using yttria-stabilized zirconia and alpha-phase alumina. These coatings are designed to withstand temperatures up to 1500°C, offering enhanced thermal protection for components in high-temperature environments.

- Integration of Smart Technologies: The integration of smart technologies into thermal protectors is another significant innovation. The National Science Foundation's Advanced Materials Opportunities report highlights the potential of incorporating sensors and actuators into thermal protection systems. These smart systems can monitor temperature changes in real-time and adjust accordingly, providing dynamic protection and improving the safety and efficiency of electronic devices and EVs.

- Sustainability in Thermal Protection Systems: Sustainability is becoming a key consideration in the development of thermal protection technologies. The U.S. Department of Energy's Energy Storage Safety Strategic Plan emphasizes the importance of developing materials and systems that not only provide effective thermal protection but also minimize environmental impact. This includes using recyclable materials and designing systems that reduce energy consumption during manufacturing and operation. These advancements in thermal protector technology are setting new standards for safety, efficiency, and sustainability across various industries. Manufacturers and industrialists should stay informed about these developments to leverage the benefits of modern thermal protection systems in their products.

Where Thermal Protectors Matter Most

Thermal protectors are crucial in several high-growth industries.

In electric vehicles, thermal protectors are embedded in drivetrains and battery management systems to prevent overheating and ensure safe operation. Thermal runaway is a major safety issue in EVs, where a battery cell experiences an uncontrolled temperature increase, potentially leading to fire or explosion. Thermal protectors help mitigate this risk by keeping temperature ranges within battery packs' optimal range.

In smart appliances, thermal protectors regulate temperature for safety, energy consumption, and product life. Smart thermostats, for example, are the leading smart energy technology installed in US homes, with 11% of households having one. These devices can learn a home’s heating and cooling patterns, and potentially save 15% of a home’s water heating energy consumption.

Industrial machinery also relies on thermal protection to prevent overheating and maintain operational stability.

Across all these industries, thermal protectors are a safety mechanism that also contributes to product performance and durability, making them essential for competitive manufacturing.

What are the Challenges to Thermal Protector Adoption?

Adopting sophisticated heat protection systems might be difficult, despite their significance. It takes engineering and may increase costs to integrate these devices into systems that are getting smaller and more complicated. Complexity in the supply chain presents additional difficulties, particularly when procuring high-performance materials. Additionally, manufacturers must guarantee that heat protection systems adhere to safety and legal requirements. To ensure that investments in thermal protection yield long-term results, industrialists must navigate these obstacles with both technical know-how and strategic strategy.

Thermal Protector Market Outlook

The market for thermal protectors is growing. According to Kings Research, the global thermal protector market was USD 67.2 million in 2023 and is expected to grow from USD 69.4 million in 2024 to USD 88.6 million by 2031, at a CAGR of 3.55%. Growth will be driven by increasing demand for thermal protection systems in electric vehicles, home appliances, and industrial equipment. As manufacturers meet safety and performance expectations, thermal protector technology will evolve, with higher efficiency, smarter integration, and improved safety.

Concluding Thoughts

Thermal protectors have evolved from simple safety devices to critical components that enable technological innovation in high-demand sectors. With surging EV adoption, growth in smart appliances, and a focus on sustainable manufacturing, their role is only set to expand. For industrial leaders, investing in advanced thermal protection is more than a compliance measure; it is a strategic decision that safeguards performance, enhances product reliability, and positions companies to lead in a rapidly evolving market.