Market Definition

The market encompasses the production and supply of high-performance sealing solutions used in medical devices and processing equipment.

These seals, including O rings, gaskets, diaphragms, and custom-molded components, ensure fluid containment, contamination prevention, and operational integrity in critical healthcare applications.

Medical Processing Seal Market Overview

The global medical processing seal market size was valued at USD 2028.3 million in 2023 and is projected to grow from USD 2171.0 million in 2024 to USD 3675.7 million by 2031, exhibiting a CAGR of 7.81% during the forecast period.

This growth is attributed to increasing demand for high-quality sealing solutions that ensure contamination control, durability, and performance in critical healthcare environments. Rising healthcare expenditures, ongoing advancements in medical device manufacturing, and stringent regulatory frameworks are further supporting this growth.

Major companies operating in the medical processing seal market are IDEX, Freudenberg Group, Sealmatic, Engineered Seal Products, MSP Seals, Inc., Global O-Ring and Seal, LLC., Dechengwang, APM Hexseal Corporation, Eastern Seals, Minnesota Rubber & Plastics, Modus Advanced, Inc., Saint-Gobain, Precision Associates, Inc., Parker Hannifin Corp, Marco Rubber and Plastics, and others.

Additionally, the expansion of pharmaceutical production and bioprocessing applications is bolstering market progress. Increasing investments in research and development, coupled with the rising adoption of automation in medical manufacturing, are enhancing efficiency and product innovation.

- In November 2024, Freudenberg exhibited at CPhI & PMEC India 2024, showcasing its high-performance sealing solutions for the pharmaceutical industry. Freudenberg-NOK India highlighted innovations such as Radiamatic HTS II Sealshygienic PTFE radial shaft seals designed for stringent medical processing seal applications.

Key Highlights:

- The medical processing seal industry size was recorded at USD 2028.3 million in 2023.

- The market is projected to grow at a CAGR of 7.81% from 2024 to 2031.

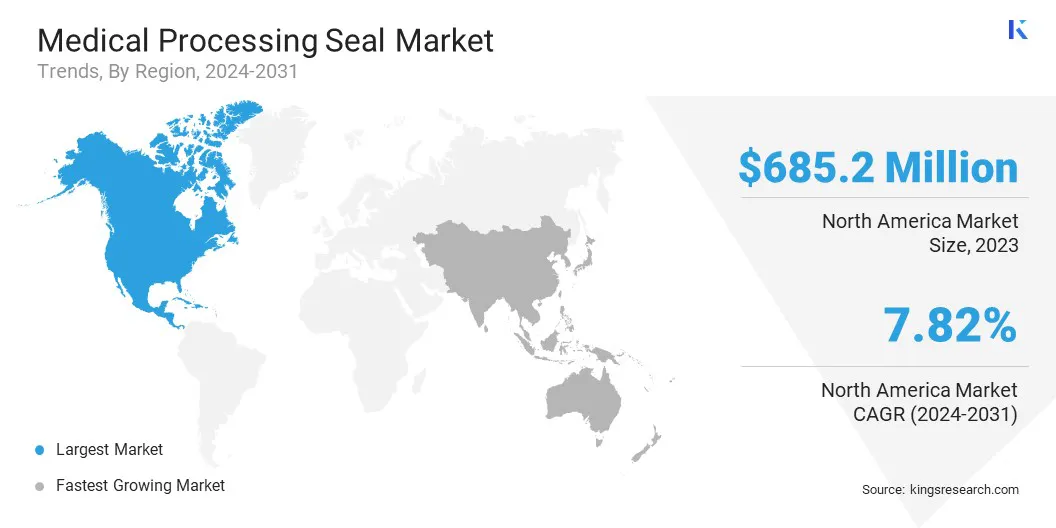

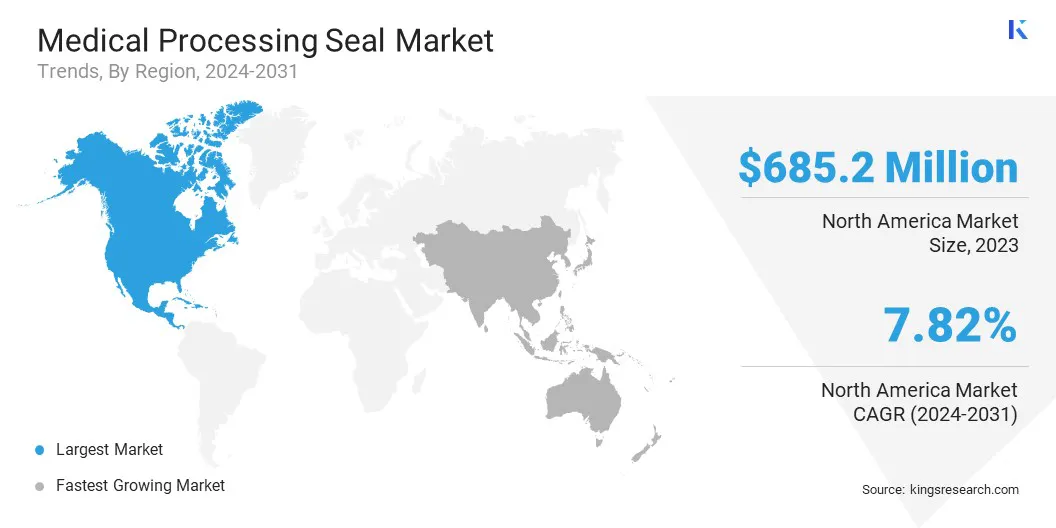

- North America held a share of 33.78% in 2023, valued at USD 685.2 million.

- The silicone segment garnered USD 543.3 million in revenue in 2023.

- The o rings segment is expected to reach USD 1173.3 million by 2031.

- Asia Pacific is anticipated to grow at a CAGR of 8.75% over the forecast period.

Market Driver

"Rising Demand for Advanced Medical Devices"

The medical processing seal market is experiencing significant growth due to the increasing demand for advanced medical devices, supported by the rising prevalence of chronic diseases and the expansion of minimally invasive surgical procedures. As healthcare facilities prioritize precision, safety, and efficiency, the need for high-quality sealing solutions in medical equipment has increased.

Medical seals are essential for ensuring contamination-free operations, fluid control, and equipment durability in devices such as ventilators, infusion pumps, and diagnostic instruments.

- In December 2024, Schreiner MediPharm, a leading provider of functional labeling for healthcare, introduced an advanced cut-through indicator for closure seals, enhancing tamper detection. This innovation strengthens pharmaceutical supply chains by ensuring product integrity, preventing counterfeiting, and offering cost-effective security..

Market Challenge

"Ensuring Seal Performance Under Harsh Sterilization Conditions"

A key challenge in the medical processing seal market is ensuring sealing integrity and performance under repeated exposure to harsh sterilization processes. Medical seals must withstand high-temperature autoclaving, gamma radiation, ethylene oxide (EtO) sterilization, and aggressive chemical cleaning agents to meet stringent hygiene and safety requirements.

To overcome this challenge, manufacturers can develop high-performance sealing materials with enhanced resistance to thermal, chemical, and radiation exposure.

Additionally, the use of proprietary coatings and surface modifications can enhance seal longevity and reduce friction, ensuring reliability over multiple sterilization cycles. Continuous investment in material innovation and collaboration with medical device manufacturers will be crucial for market competitiveness.

Market Trend

"Growing Adoption of High-Performance Elastomers"

A key trend influencing the medical processing seal market is the increasing use of high-performance elastomers and specialty polymers to enhance sealing efficiency in medical applications.

With the healthcare industry demanding greater durability, chemical resistance, and sterility, traditional rubber-based seals are being replaced by advanced materials such as liquid silicone rubber (LSR), perfluoroelastomers (FFKM), and thermoplastic elastomers (TPE).

These materials offer superior resistance to extreme temperatures, aggressive chemicals, and repeated sterilization cycles, making them ideal for pharmaceutical processing, fluid management systems, and diagnostic equipment.

- In April 2023, Solvay expanded its Tecnoflon SHP FFKM portfolio, enhancing the market with high-performance, chemically resistant sealing solutions for pharmaceutical processing, diagnostic equipment, and surgical instruments.

Medical Processing Seal Market Report Snapshot

|

Segmentation

|

Details

|

|

By Material

|

Silicone, Ethylene Propylene Diene Monomer (EPDM), Metal, PTFE, Others

|

|

By Product

|

O Rings, Gaskets, Lip Seals, Others

|

|

By Region

|

North America: U.S., Canada, Mexico

|

|

Europe: France, U.K., Spain, Germany, Italy, Russia, Rest of Europe

|

|

Asia-Pacific: China, Japan, India, Australia, ASEAN, South Korea, Rest of Asia-Pacific

|

|

Middle East & Africa: Turkey, UAE, Saudi Arabia, South Africa, Rest of Middle East & Africa

|

|

South America: Brazil, Argentina, Rest of South America

|

Market Segmentation

- By Material (Silicone, Ethylene Propylene Diene Monomer (EPDM), Metal, PTFE, and Others): The silicone segment earned USD 543.3 million in 2023 due to its exceptional biocompatibility, flexibility, and resistance to extreme temperatures and chemicals. Widely used in medical devices, fluid management systems, and pharmaceutical processing equipment, silicone seals ensure durability, sterility, and sealing integrity in demanding conditions.

- By Product (O Rings, Gaskets, Lip Seals, and Others): The o rings segment held a share of 31.90% in 2023, fueled by its cost-effectiveness, versatility, and ability to provide leak-proof sealing in various medical applications.

Medical Processing Seal Market Regional Analysis

Based on region, the global market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America.

North America medical processing seal market captured a share of around 33.78% in 2023, valued at USD 685.2 million. This dominance is reinforced by the region’s well-established healthcare system, stringent regulatory standards, and high demand for advanced medical devices.

The presence of leading medical equipment manufacturers, along with strong R&D investments in material innovation and biocompatible sealing solutions, further supports regional market growth.

Additionally, increasing healthcare expenditures, the rising prevalence of chronic diseases, and the rapid adoption of minimally invasive surgical procedures contribute to the sustained demand for high-quality medical seals in the region.

- In July 2024, the U.S. Food and Drug Administration (FDA), reported that chronic cardiovascular diseases account for seven of the ten leading causes of mortality in the United States, highlighting a significant public health challenge and increasing demand for advanced medical solutions.

Asia Pacific medical processing seal industry is poised to grow at a CAGR of 8.75% over the forecast period. This growth is propelled by rapid industrialization, increasing healthcare investments, and rising demand for medical devices across emerging economies such as China, India, and Japan.

The regional market benefits from expanding pharmaceutical production, advancements in medical technology, and a growing aging population requiring advanced healthcare solutions. Additionally, government initiatives to strengthen local manufacturing, expand healthcare access, and enforce stringent regulations are expected to accelerate regional market growth.

Regulatory Frameworks

- In the U.S., the Food and Drug Administration (FDA) regulates the market by overseeing the approval, safety, and quality of sealing components used in medical devices and pharmaceutical processing.

- In Europe, the European Medicines Agency (EMA) regulates the safety, quality, and performance of medical components used in pharmaceutical and bioprocessing applications, including medical processing seals that come into direct contact with drugs or biologics.

Competitive Landscape

The medical processing seal industry is characterized by a large number of participants, including both established corporations and emerging players. Market participants focus on product innovation, material advancements, regulatory compliance, and strategic partnerships to strengthen their market position.

They further invest in R&D to develop high-performance sealing solutions that meet the increasing demand for biocompatibility, chemical resistance, and durability in medical applications. The market also witnesses mergers, acquisitions, and collaborations as companies seek to expand their geographic footprint and enhance their product portfolios.

Additionally, technological advancements such as antimicrobial coatings, self-lubricating seals, and miniaturized sealing solutions are shaping the competitive landscape. Regional players in Asia Pacific and other emerging markets are offering cost-effective solutions and leveraging local manufacturing capabilities to meet growing demand.

List of Key Companies in Medical Processing Seal Market:

- IDEX

- Freudenberg Group

- Sealmatic

- Engineered Seal Products

- MSP Seals, Inc.

- Global O-Ring and Seal, LLC.

- Dechengwang

- APM Hexseal Corporation

- Eastern Seals

- Minnesota Rubber & Plastics

- Modus Advanced, Inc.

- Saint-Gobain

- Precision Associates, Inc.

- Parker Hannifin Corp

- Marco Rubber and Plastics

Recent Developments (M&A/New Product Launch)

- In October 2024, Trelleborg Sealing Solutions acquired CRC Distribution, enhancing its presence in the U.S. sealing market and expanding its capabilities in polymer sealing solutions for medical devices, pumps, compressors, and other critical industries.

- In March 2024, Bostik introduced the first industrial compostable cold seal at ASC Annual Convention & Expo 2024, reflecting the increasing demand for sustainable solutions and driving innovation in eco-friendly, high-performance sealing materials.