Market Definition

The market involves a virtual ecosystem that integrates physical and digital environments using technologies like XR, AI, blockchain, and digital twins. It enables real-time monitoring, simulation, and collaboration across industries, enhancing product design, production, and maintenance.

The report examines critical driving factors, industry trends, regional developments, and regulatory frameworks impacting market growth through the projection period.

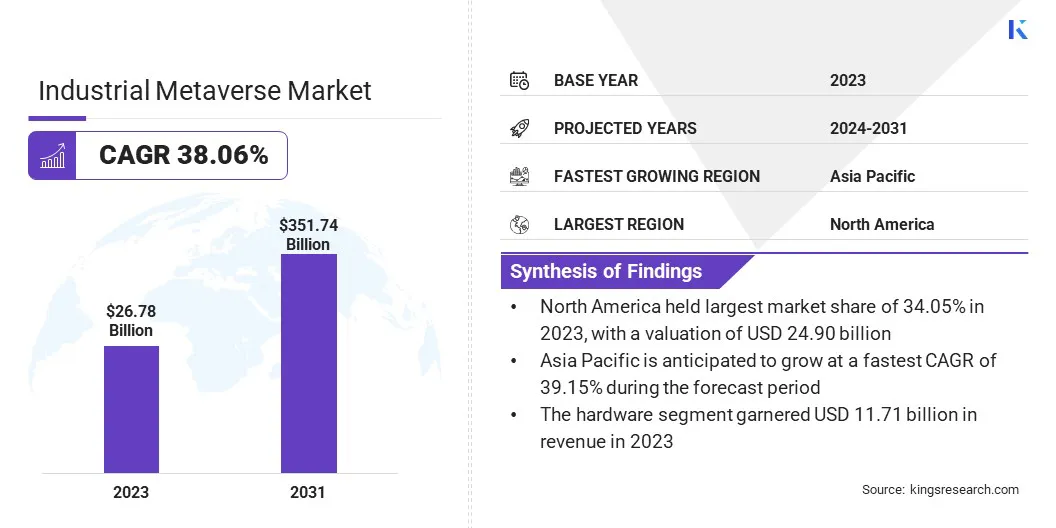

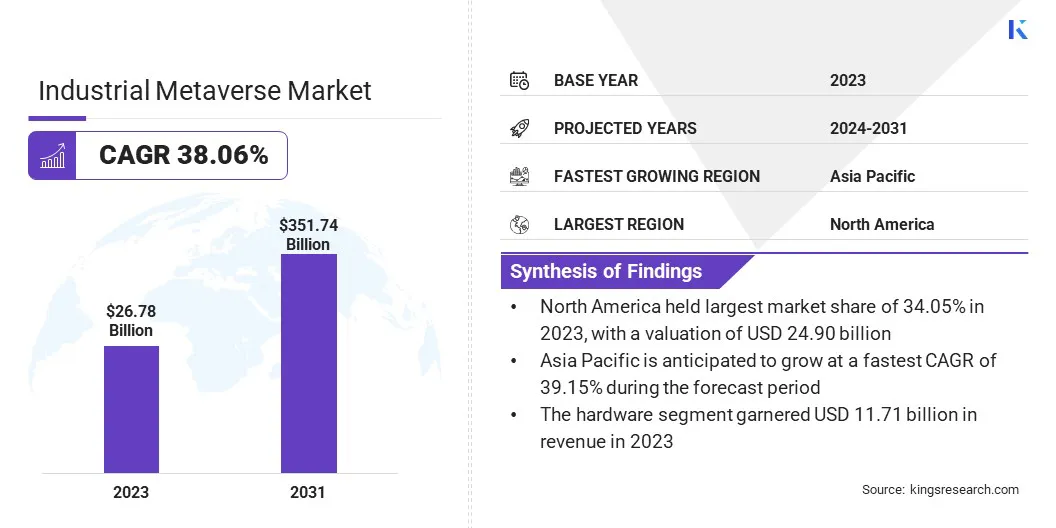

The global industrial metaverse market size was valued at USD 26.78 billion in 2023 and is projected to grow from USD 36.78 billion in 2024 to USD 351.74 billion by 2031, exhibiting a CAGR of 38.06% during the forecast period.

The market is rapidly evolving, driven by advancements in technologies like XR, AI, blockchain, and 6G, which are transforming industrial operations globally. As industries adopt digital twins and immersive solutions, regulations around data privacy, security, and interoperability are becoming increasingly important to ensure safe and efficient deployment.

Major companies operating in the industrial metaverse industry are NVIDIA, Microsoft, Siemens AG, Amazon Web Services, Meta, IBM, ABB, HTC Corporation, PTC, Dassault Systèmes, Bentley Systems, Magic Leap, Swanson Analysis Systems Inc., Unity Software Inc., and Matterport.

Continuous advancements in enabling technologies such as Augmented Reality (AR), Virtual Reality (VR), Artificial Intelligence (AI), and the Internet of Things (IoT) are crucial driving factors for the growth of the industrial metaverse.

These technologies provide immersive experiences, enhance data analytics capabilities, and improve real-time decision-making by connecting physical and virtual systems.

The integration of AR and VR allows for more efficient training, design, and remote monitoring, while AI and IoT enable predictive maintenance and automation, further optimizing industrial operations. The ongoing evolution of these technologies is currently driving innovation, enhancing productivity and efficiency across industries.

- In May 2024, researchers from the Hong Kong Polytechnic University introduced an AI-supported digital framework for transportation and logistics, exploring the role of the metaverse in enhancing operations. The framework integrates technologies like AI, blockchain, digital twins, and extended reality to optimize decision-making and improve efficiency in the industry.

Key Highlights

- The industrial metaverse market size was recorded at USD 26.78 billion in 2023.

- The market is projected to grow at a CAGR of 38.06% from 2024 to 2031.

- North America held a market share of 34.05% in 2023, with a valuation of USD 9.12 billion.

- The hardware segment garnered USD 11.71 billion in revenue in 2023.

- The AR segment is expected to reach USD 154.80 billion by 2031.

- The data visualization & analytics segment secured the largest revenue share of 34.75% in 2023.

- The automotive segment is poised for a robust CAGR of 39.72% through the forecast period.

- Asia Pacific is anticipated to grow at a CAGR of 39.15%during the forecast period.

Market Driver

Focus on Human-Centric, Collaborative Interaction Supporting Industry 5.0

A key market driver in the market is the emphasis on human-centric, collaborative interactions that align with Industry 5.0 principles. This approach enhances both human-to-human and human-machine communication within virtual environments, enabling more effective teamwork and task execution.

By prioritizing user engagement and collaboration, these technologies support increased productivity and innovation. As a result, solutions that foster seamless interaction are gaining traction, driving broader adoption of Industrial Metaverse platforms.

- In 2024, Researchers from the University of León proposed a novel technological framework for the Industrial Metaverse, integrating VR, Digital Twins, and IIoT to create a human-centered, immersive virtual industrial environment.A functional demonstrator was developed and evaluated, showing effective human-to-human and human-machine interaction in virtual environments, supporting collaborative tasks and advancing the human-centric approach of Industry 5.0.

Market Challenge

Challenge of Data Interoperability in the Industrial Metaverse

One of the most significant challenges in the Industrial Metaverse market is ensuring data interoperability when integrating new metaverse technologies with existing industrial systems.

Traditional industrial infrastructure often relies on proprietary protocols and outdated data formats that are incompatible with advanced digital solutions such as AI, digital twins, and extended reality (XR). This misalignment hinders real-time data exchange, limiting the potential of integrated metaverse applications.

To address this challenge, organizations are focusing on developing open, standardized frameworks and platforms that promote better integration between new and existing systems, ensuring smooth data flow and enhancing operational efficiency.

Market Trend

Integration of Spatial Computing with Virtual Twins for Enhanced Collaboration

A key trend in the market is the convergence of spatial computing with virtual twin technology to deliver immersive, interactive experiences. This enables real-time visualization and manipulation of digital assets within physical environments, fostering seamless collaboration across teams.

By utilizing advanced sensing and tracking capabilities, spatial computing improves precision and engagement, driving more informed decision-making and operational efficiencies. This approach is accelerating the adoption of mixed reality solutions that integrate digital and physical workflows, creating new value in industrial operations.

- In February 2025, Dassault Systèmes announced that 3D UNIV+RSES powered by the 3DEXPERIENCE platform will leverage the power of spatial computing with the new “3DLive” visionOS app, available this summer. This app enables virtual twins to leap off the screen into a user’s physical space, allowing real-time visualization and team collaboration in lifelike environments. The collaboration with Apple integrates Apple Vision Pro’s advanced cameras, sensors, and tracking to interact with the physical world with scientific accuracy.

|

Segmentation

|

Details

|

|

By Component

|

Software, Hardware, Services

|

|

By Technology

|

AR, VR, MR

|

|

By Application

|

Product Design & Development, Virtual Prototyping, Training & Simulation, Remote Collaboration, Maintenance & Repair, Supply Chain Optimization, Data Visualization & Analytics

|

|

By End Use

|

Automotive, Healthcare, Logistics & Transportation, Manufacturing, Energy and utilities, Others

|

|

By Region

|

North America: U.S., Canada, Mexico

|

|

Europe: France, UK, Spain, Germany, Italy, Russia, Rest of Europe

|

|

Asia-Pacific: China, Japan, India, Australia, ASEAN, South Korea, Rest of Asia-Pacific

|

|

Middle East & Africa: Turkey, U.A.E., Saudi Arabia, South Africa, Rest of Middle East & Africa

|

|

South America: Brazil, Argentina, Rest of South America

|

Market Segmentation:

- By Component (Software, Hardware, Services): The hardware segment earned USD 11.71 billion in 2023 due to increased demand for advanced metaverse-compatible devices and immersive technologies.

- By Technology (AR, VR, MR): The AR segment held 43.30% of the market in 2023, due to its widespread adoption in industrial applications for real-time data visualization and remote assistance.

- By Application (Product Design & Development, Virtual Prototyping, Training & Simulation, Remote Collaboration, Maintenance & Repair, Supply Chain Optimization, Data Visualization & Analytics): The data visualization & analytics segment is projected to reach USD 127.65 billion by 2031, owing to increasing demand for real-time data insights, enhanced decision-making capabilities, and the adoption of AI-driven analytics across industries..

- By End Use (Automotive, Healthcare, Logistics & Transportation, Manufacturing, Energy and utilities, Others): The automotive segment is poised for significant growth at a CAGR of 39.72% through the forecast period due to the increasing adoption of advanced technologies like AI, AR, and autonomous driving systems.

Based on region, the global market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and South America.

North America industrial metaverse market share stood at around 34.05% in 2023, with a valuation of USD 9.12 billion. The market is driven by the region’s technological leadership in XR, AI, blockchain, and digital twin technologies, along with a strong industrial base in sectors such as manufacturing, aerospace, and automotive.

Significant investments in R&D by major tech and industrial players, combined with a supportive regulatory environment, have accelerated the integration of metaverse solutions across industrial applications. Additionally, increasing demand for enhanced operational efficiency, real-time data analytics, and improved remote collaboration is fueling market growth.

The rise of digital transformation initiatives and the transition toward Industry 4.0 and Industry 5.0 frameworks further contribute to the widespread adoption of Industrial Metaverse technologies.

Asia-Pacific industrial metaverse industry is poised for significant growth at a robust CAGR of 39.15% over the forecast period. The increasing adoption of digital twins and simulation technologies is accelerating the shift toward automation and the development of smart factories in the Asia-Pacific region.

By enabling virtual modeling and real-time monitoring of physical assets, these technologies optimize production processes, enhance predictive maintenance, and reduce operational risks.

This integration drives efficiency gains, lowers costs, and supports data-driven decision-making, making smart factory implementations more scalable and effective. Consequently, businesses can achieve higher productivity and agility in an increasingly competitive industrial landscape.

- In September 2023, China’s Ministry of Industry and Information Technology (MIIT) released a Three-Year Action Plan for the Industrial Innovation and Development of the Metaverse, aiming to stimulate economic growth, job creation, and industrial digitalization. This plan focuses on integrating technologies like AI, blockchain, and VR into sectors such as manufacturing, automotive, and aerospace, promoting the development of industrial clusters and enhancing real-time simulations and digital twin applications.

Regulatory Frameworks

- In the U.S., the market is primarily influenced by the National Institute of Standards and Technology (NIST), which sets cybersecurity and data protection frameworks critical for industrial digital environments. The Occupational Safety and Health Administration (OSHA) oversees worker safety regulations to ensure the safe implementation of immersive and virtual technologies in industrial settings.

- In the EU, the market is shaped by regulations such as GDPR for data protection and the AI Act for safe AI deployment. Additionally, the European Data Strategy and Digital Markets Act promotes interoperability and competition, ensuring the industrial metaverse develops securely and responsibly across Europe.

Competitive Landscape

The industrial metaverse market is characterized by a large number of participants, including both established corporations and rising organizations. Key players are growing their businesses through a combination of strategic collaborations, investments, and technological advancements.

Market players are also partnering with technology providers to integrate AI, VR/AR, and digital twins into their offerings, enabling efficient and scalable industrial solutions.

Mergers and acquisitions are also common as companies seek to expand their portfolios and gain access to new technologies, while investments in R&D help accelerate the development of innovative solutions tailored for various industrial applications. These strategies are enabling key players to strengthen their positions in the rapidly growing market.

- In January 2024, Siemens and Sony entered a strategic partnership to advance immersive engineering solutions. The collaboration integrates Siemens’ Xcelerator software portfolio with Sony’s spatial content creation system. This combined solution enables intuitive 3D design experiences, aiming to accelerate innovation in the industrial metaverse by enhancing real-time collaboration and engineering workflows.

List of Key Companies in Industrial Metaverse Market:

- NVIDIA Corporation

- Microsoft

- Siemens AG

- Amazon Web Services

- Meta Platforms Inc.

- IBM

- PTC

- HTC Corporation

- ABB

- Dassault Systèmes

- Bentley Systems

- Magic Leap

- Swanson Analysis Systems Inc.

- Unity Software Inc.

- Matterport

Recent Developments (/Product Launch)

- In June 2024, Siemens advanced the Industrial Metaverse landscape by showcasing successful deployments of Digital Twin technology across sectors like manufacturing, infrastructure, and urban planning. Through projects such as the Siemensstadt Square in Berlin, Egypt’s high-speed railway, and collaborations with partners like Nvidia and Freyr, Siemens demonstrated the real-world impact of Digital Twins in boosting productivity, efficiency, and sustainability. These efforts, supported by the Siemens Xcelerator platform, reflect the growing market demand for AI-driven, scalable, and collaborative industrial digitalization solutions.