Market Definition

The market involves the production of finely powdered metals through atomization techniques that convert molten metal into small, uniform particles. To produce these powders, molten metal is broken down through water, gas, or plasma atomization depending on the required particle characteristics and end-use applications.

The resulting powders are used in additive manufacturing, powder metallurgy, thermal spraying, and metal injection molding. They are derived from metals and alloys like aluminum, copper, stainless steel, and titanium. Industries such as aerospace, automotive, and medical rely on these materials for producing lightweight structures, wear-resistant coatings, and high-precision components.

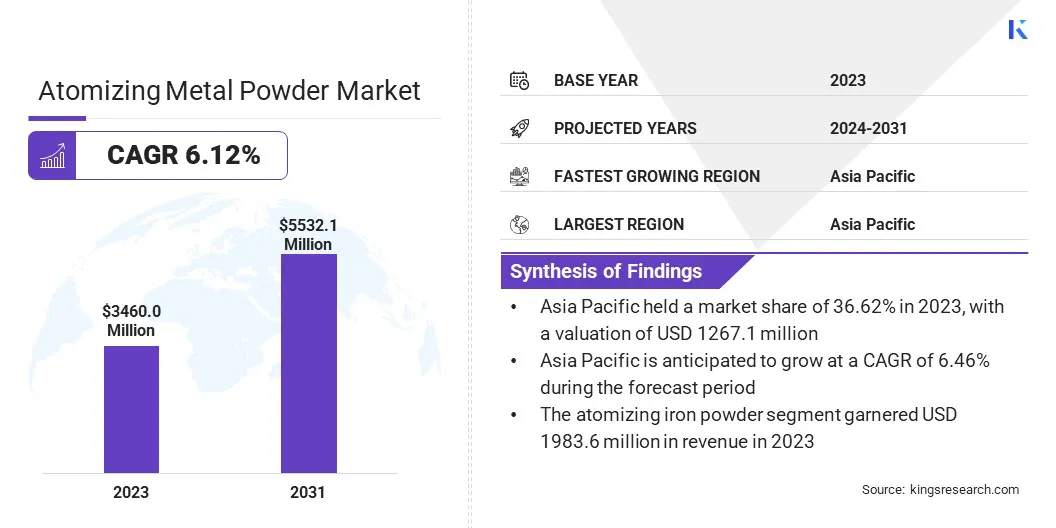

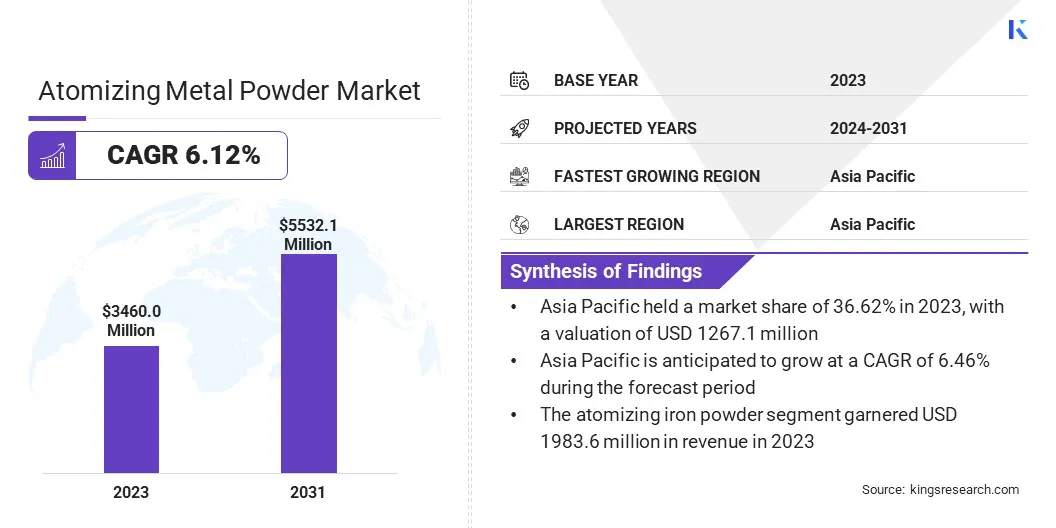

The global atomizing metal powder market size was valued at USD 3,460.0 million in 2023 and is projected to grow from USD 3,649.7 million in 2024 to USD 5,532.1 million by 2031, exhibiting a CAGR of 6.12% during the forecast period.

The market is expanding due to the surging demand for high-performance alloy powders, particularly in industries such as aerospace, automotive, and energy, where enhanced strength, thermal resistance, and durability are critical.

Additionally, manufacturers are increasingly adopting additive manufacturing and powder metallurgy techniques, which is driving the need for high-quality metal powders, to produce complex, lightweight components with improved mechanical performance and production efficiency.

Major companies operating in the atomizing metal powder industry are Höganäs AB, GKN Powder Metallurgy, Kymera International, Sandvik AB, Mitsui Mining & Smelting Co., Ltd., Rio Tinto Metal Powders, Pometon S.p.A., Kobe Steel, Ltd., JFE Steel Corporation, Carpenter Technology Corporation, Epson Atmix Corporation, Sumitomo Electric Industries, Ltd., Daido Steel Co., Ltd., Atomising Systems Limited, and American Chemet Corporation.

The increasing reliance on additive manufacturing and powder metallurgy is accelerating the growth of the market. Industries such as aerospace, automotive, and medical are leveraging these technologies to produce high-performance components with complex geometries and enhanced material properties.

The demand for precision-engineered parts continues to rise, prompting manufacturers to invest in high-quality metal powders. Continuous advancements in 3D printing and sintering technologies are further strengthening the adoption of atomized metal powders across various industrial applications.

Key Highlights

- The atomizing metal powder industry size was recorded at USD 3,460.0 million in 2023.

- The market is projected to grow at a CAGR of 6.12% from 2024 to 2031.

- Asia Pacific held a market share of 36.62% in 2023, with a valuation of USD 1,267.1 million.

- The atomizing iron powder segment garnered USD 1,983.6 million in revenue in 2023.

- The powder metallurgy segment is expected to reach USD 1,773.5 million by 2031.

- Europe is anticipated to grow at a CAGR of 6.46% during the forecast period.

Market Driver

How will the need for High-Performance Alloy Powders drive the market?

The market is propelled by the increasing demand for high-performance alloy powders across critical sectors such as automotive, and electronics. These industries require metal powders with superior mechanical properties, including strength, wear resistance, and thermal stability, to support the production of complex, high-precision components.

Manufacturers are investing in advanced material formulations and atomization technologies to meet the performance demands of additive manufacturing and other powder-based production methods.

- In May 2025, Eplus3D showcased meter-scale copper alloy components at TCT Asia 2025, following the success of its 64-laser EP-M2050 system, a cutting-edge large-format metal 3D printing solution.

Such advancements reinforce the growing need for reliable and specialized alloy powders. As end-use industries adopt high-speed additive manufacturing at scale, the requirement for atomized metal powders with consistent quality and performance continues to rise, further driving market growth.

Market Challenge

What are the negative implications of high production cost and material waste?

The atomizing metal powder market faces challenges due to high production costs and material waste associated with powder manufacturing processes. Atomization is energy-intensive, and achieving precise particle size distribution adds to the expenses, making it difficult for manufacturers to remain cost-efficient.

To mitigate these issues, companies are optimizing atomization methods, improving powder yield, and incorporating advanced recycling techniques.

The use of re-atomization technologies and closed-loop recycling systems helps reduce material waste and enhance powder quality. Additionally, investments in energy-efficient processes and automation are helping lower operational costs, thus supporting the market's growth.

Market Trend

What will be the impact of space explorations programs in this market?

The increasing investments in aerospace and space exploration are positively impacting the market. Metal powders are essential in the production of lightweight, high-strength components for aircraft, satellites, and propulsion systems.

The growing need for fuel-efficient aircraft and durable space-grade materials is driving demand for high-purity powders such as titanium, aluminum, and nickel alloys. The aerospace sector’s focus on advanced manufacturing techniques, including additive manufacturing, is further accelerating market expansion.

- In November 2024, JX Advanced Metals Corporation introduced a copper powder specifically designed for laser powder bed fusion additive manufacturing (AM) applications, leveraging their proprietary surface treatment technology. The copper powder is anticipated to find applications across various sectors, including rocket engine cooling mechanisms and induction heating coils, due to its ability to reduce size, weight, and delivery time, along with its enhanced performance capabilities.

|

Segmentation

|

Details

|

|

By Product

|

Atomizing Iron Powder, Atomizing Copper Powder

|

|

By Application

|

Additive Manufacturing, Powder Metallurgy, Metal Injection Molding (MIM), Thermal Spraying, Others

|

|

By Region

|

North America: U.S., Canada, Mexico

|

|

Europe: France, UK, Spain, Germany, Italy, Russia, Rest of Europe

|

|

Asia-Pacific: China, Japan, India, Australia, ASEAN, South Korea, Rest of Asia-Pacific

|

|

Middle East & Africa: Turkey, UAE, Saudi Arabia, South Africa, Rest of Middle East & Africa

|

|

South America: Brazil, Argentina, Rest of South America

|

Market Segmentation:

- By Product (Atomizing Iron Powder, Atomizing Copper Powder): The atomizing iron powder segment earned USD 1,983.6 million in 2023 due to its extensive use in powder metallurgy, automotive components, and soft magnetic applications, driven by cost-effectiveness, high compressibility, and superior sintering properties that enhance manufacturing efficiency and product performance.

- By Application (Additive Manufacturing, Powder Metallurgy, Metal Injection Molding (MIM), Thermal Spraying, Others): The powder metallurgy segment held 33.15% of the market in 2023, due to its widespread adoption in manufacturing high-precision components with superior mechanical properties and cost efficiency, and minimal material waste.

Based on region, the global market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America.

The Asia Pacific atomizing metal powder market share stood around 36.62% in 2023 in the global market, with a valuation of USD 1,267.1 million. The region continues to serve as a major manufacturing center, with countries like China, Japan, South Korea, and India leading production activities.

Growth in consumer electronics and the automotive sector is supporting increased adoption of advanced manufacturing techniques like additive manufacturing and powder metallurgy, that rely on metal powders to produce lightweight, high-strength components.

Additionally, the rising electric vehicle (EV) production across the Asia Pacific is further driving the need for specialized metal powders used in manufacturing battery components, motor parts, and thermal management systems.

- In November 2023, HP Inc. entered a strategic partnership with Indo-MIM Private Limited, a major player in metal injection molding and an emerging contributor in additive manufacturing powders. The collaboration aims to advance metal additive manufacturing by expanding material capabilities, improving precision, and boosting production efficiency.

Europe is poised for significant growth in the atomizing metal powder industry, with a robust CAGR of 6.23% over the forecast period. The region is actively adopting additive manufacturing (AM) technologies within high-end industries such as aerospace, automotive, and healthcare.

European manufacturers are increasingly relying on AM to produce complex, lightweight, and customizable components. The continued integration of AM across these sectors is driving demand for specialized, high-quality metal powders, which, in turn is driving the growth of the market in this region.

Regulatory Frameworks

- The U.S. government regulates the atomizing metal powder industry through the Environmental Protection Agency (EPA), which enforces air and water quality standards. OSHA sets safety guidelines for handling hazardous materials, while ASTM International provides standards for metal powder quality, particularly in additive manufacturing and other industrial applications.

- The EU’s REACH regulation, managed by the European Chemicals Agency (ECHA), governs the safe production and use of chemicals, including metal powders. Additionally, the EU’s Directive 89/391/EEC mandates workplace safety, ensuring that metal powder manufacturers comply with regulations to protect worker health and control hazardous exposure to metal dust.

- In China, the State Administration for Market Regulation (SAMR) enforces product quality standards for metal powders, while the Ministry of Ecology and Environment (MEE) regulates environmental compliance. The GB/T 5283-2017 standard ensures the consistency and safety of metal powders used in additive manufacturing and other industrial applications, ensuring quality control.

- In South Korea, the Ministry of Environment (MOE) regulates the environmental impact of metal powder manufacturing, focusing on emissions and waste management. The Korea Occupational Safety and Health Agency (KOSHA) enforces safety standards to protect workers from exposure to metal dust and fumes, ensuring a safe working environment for manufacturers.

Competitive Landscape

The atomizing metal powder market is characterized by market players focusing on the development of advanced tools for Metal Injection Molding (MIM) to improve production efficiency and material performance, strengthening their competitive edge.

Companies are introducing specialized metal powders designed for MIM applications, addressing growing industry requirements for enhanced durability, precision, and scalability. These efforts are aimed at strengthening their market position and meeting the evolving demands of sectors such as automotive, aerospace, and medical.

- In September 2024, Sandvik launched Osprey HWTS 50, a lean hot-work tool steel powder engineered for enhanced printability in additive manufacturing. This alloy, with lower carbon content and optimized carbide-forming elements, offers improved hot hardness, tempering resistance, and thermal conductivity, making it suitable for applications such as high-pressure die-casting dies, injection molds, and hot-forming tools.

List of Key Companies in Atomizing Metal Powder Market:

- Höganäs AB

- GKN Powder Metallurgy

- Kymera International

- Sandvik AB

- Mitsui Mining & Smelting Co., Ltd.

- Rio Tinto Metal Powders

- Pometon S.p.A.

- Kobe Steel, Ltd.

- JFE Steel Corporation

- Carpenter Technology Corporation

- Epson Atmix Corporation

- Sumitomo Electric Industries, Ltd.

- Daido Steel Co., Ltd.

- Atomising Systems Limited

- American Chemet Corporation

Recent Developments (Product Launch)

- In September 2024, Desktop Metal, Inc. tested and approved a 100% recycled nickel-based superalloy, re-atomized Mar-M247, produced using Continuum Powders' proprietary technology. The alloy is now R&D Qualified for Desktop Metal’s binder jet 3D printing portfolio. This enhances the company’s sustainability goals and bolsters its eco-friendly additive manufacturing capabilities.

The ability of these powders to meet stringent material and performance standards is supporting market expansion, positioning Europe as a key contributor to global market growth