Market Definition

The market involves the use of Internet of Things technologies to improve operations in chemical manufacturing. It includes real-time monitoring, predictive maintenance, process optimization, energy management, and improved safety and compliance. This market is growing as chemical companies seek to boost efficiency, reduce costs, improve product quality, and ensure sustainability through IoT solutions.

IoT in Chemical Market Overview

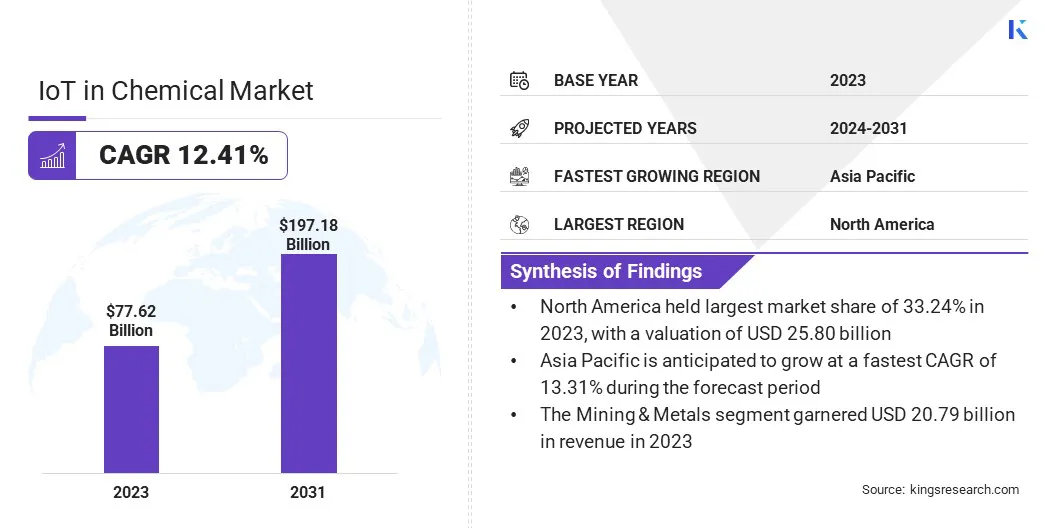

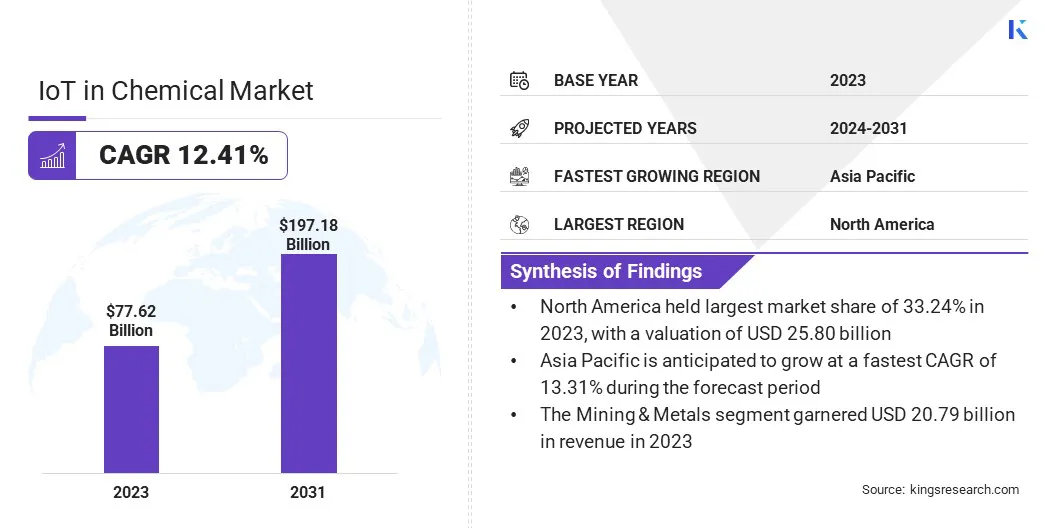

Global IoT in chemical market size was valued at USD 77.62 billion in 2023, which is estimated to be valued at USD 86.93 billion in 2024 and reach USD 197.18 billion by 2031, growing at a CAGR of 12.41% from 2024 to 2031.

IoT boosts operational efficiency by enabling real-time monitoring of key parameters, allowing chemical plants to adjust processes instantly. This minimizes inefficiencies, reduces downtime, and ensures optimal performance, which leads to cost savings and increased productivity in the industry.

Key Market Highlights:

- The IoT in Chemical industry size was recorded at USD 77.62 billion in 2023.

- The market is projected to grow at a CAGR of 12.41% from 2024 to 2031.

- North America held a market share of 33.24% in 2023, with a valuation of USD 25.80 billion.

- The machine vision segment garnered USD 9.58 billion in revenue in 2023.

- The mining & metals segment is expected to reach USD 84 billion by 2031.

- Asia Pacific is anticipated to grow at a CAGR of 13.31% during the forecast period.

Major companies operating in the IoT in chemical market are Siemens, Endress+Hauser Group Services AG, ABB, Rockwell Automation Inc, Emerson Electric Co. , Yokogawa Electric Corporation, Honeywell International Inc, Schneider Electric, Open Automation Software, Inc. , Microsoft , Bayer AG, AstraZeneca , Intel Corporation, SAP , Evoort Solutions, and others.

The IoT in the chemical market is evolving rapidly, driven by the increasing demand for automation and digitalization in manufacturing processes. Companies in this sector are adopting IoT solutions to enhance operational efficiency, improve safety, and optimize resource use.

Real-time monitoring, predictive maintenance, and process optimization are key aspects of IOT. The market is characterized by a shift toward smarter, more connected plants, enabling better decision-making, reduced downtime, and improved product quality.

- In April 2023, Tata Chemicals partnered with TCS to implement digital twin technology for enhancing operational efficiency at its Mithapur plant in India. This IoT-driven solution helped optimize processes, reduce energy consumption, and improve product yield, aligning with Industry 4.0 goals.

Improved Operational Efficiency

Improved operational efficiency is a key driverin the IoT in chemical market. IoT enables real-time monitoring of equipment and processes offering insights that help identify inefficiencies and prevent downtime.

This allows manufacturers to optimize production, reduce waste, and use resources more effectively. This results in lower operational costs, higher throughput, and improved product quality.

- In August 2024, Neilsoft launched its subsidiary, Neil Automation, to offer manufacturing & building automation and digital factory solutions in India. Through IoT-driven energy management and digital twin technologies, Neil Automation aims to enhance manufacturing efficiency, energy consumption monitoring, and quality inspection for industries transitioning to Industry 4.0.

Data Overload

Data overload poses a major challenge in the chemical industry’s IoT market, as the vast amount of data generated by sensors and devices can overwhelm existing systems and staff. This often leads to inefficiencies in data analysis and decision-making.

To address this, implementing advanced analytics platforms, such as AI and machine learning, can help process and interpret large datasets efficiently. Additionally, cloud-based solutions can provide scalable storage and real-time data processing enabling faster decision-making without straining internal resources.

Integration of AI and Machine Learning

The integration of AI and machine learning within IoT systems is transforming the chemical industry by enhancing predictive maintenance, process optimization, and decision-making. These advanced technologies enable real-time data analysis, improving operational efficiency and reducing downtime.

AI-driven models can predict equipment failures before they occur, optimize production processes for higher yields, and support smarter decision-making through continuous monitoring. This integration enhances overall productivity, reduces costs, and ensures more sustainable and reliable operations in chemical manufacturing environments.

- In May 2024, Qualcomm Technologies partnered with Aramco to drive digital transformation in Saudi Arabia. This collaboration aims to advance industrial IoT, AI, and 5G technologies, utilizing cellular technology and the 450MHz spectrum to enhance connectivity and industrial solutions.

IoT in Chemical Market Report Snapshot

|

Segmentation

|

Details

|

|

By Technology

|

Machine Vision, 3D printing, Digital Twin, Plant Asset Management, Distributed Control Systems, Industrial Robotics, Big Data, Artificial Intelligence, AR and VR, Others

|

|

By Application

|

Mining & Metals, Food & Beverages, Chemicals (Petrochemicals & Polymers, Specialty Chemicals, Fertilizers & Agrochemicals, Others), Pharmaceuticals, Paper & Pulp

|

|

By Region

|

North America: U.S., Canada, Mexico

|

|

Europe: France, U.K., Spain, Germany, Italy, Russia, Rest of Europe

|

|

Asia-Pacific: China, Japan, India, Australia, ASEAN, South Korea, Rest of Asia-Pacific

|

|

Middle East & Africa: Turkey, UAE, Saudi Arabia, South Africa, Rest of Middle East & Africa

|

|

South America: Brazil, Argentina, Rest of South America

|

Market Segmentation:

- By Technology (Machine Vision, 3D printing, Digital Twin, Plant Asset Management, Distributed Control Systems, Industrial Robotics, Big Data, Artificial Intelligence, AR and VR, Others): The machine vision segment earned USD 9.58 billion in 2023 due to the increasing demand for automation, precision in manufacturing, and advancements in artificial intelligence and image recognition technologies.

- By Application (Mining & Metals, Food & Beverages, Chemicals, Pharmaceuticals, Paper & Pulp): The mining & metals held 31.86% of the market in 2023 due to rising industrial applications, the need for improved safety measures, and the integration of IoT solutions for enhanced operational efficiency.

IoT in Chemical Market Regional Analysis

Based on region, the market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America.

North America IoT in chemical market share stood around 33.24% in 2023 in the global market, with a valuation of USD 25.80 billion. This dominance is attributed to the chemical industry due to its advanced infrastructure and technological innovations in the chemical industry.

Additionally, presence of key players and manufacturers furtherfuels the growth of the market in this region. North America’s chemical industry is rapidly adopting IoT technologies to improve operational efficiency, safety, and sustainability. The region’s regulatory frameworks and supportive government policies further supports the widespread implementation of IoT across chemical manufacturing and processing plants.

The IoT in the chemical industry in Asia Pacific is expacted to grow at a robust CAGR of 13.31% over the forecast period. Asia Pacific is the fastest-growing region for market, driven by rapid industrialization and technological advancements. Countries like China and India are investing heavily in IoT solutions to modernize their chemical industries and optimize production processes.

The increasing demand for operational efficiency, coupled with the region's large chemical manufacturing base, propels the adoption of IoT technologies. Additionally, government initiatives promoting smart manufacturing and digital transformation in the Asia Pacific region further accelerate IoT integration in the chemical sector.

- In December 2024, Sattrix Information Security partnered with Cloud IOT to enhance cybersecurity in Southeast Asia. Combining Sattrix's global expertise with Cloud IOT's local presence, the venture focuses on providing cybersecurity solutions for industries like finance, healthcare, retail, and manufacturing, addressing regional cyber threats.

Regulatory Frameworks

- In U.S., the NIST Cybersecurity Framework helps businesses of all sizes better understand, manage, and reduce their cybersecurity risk and protect their networks and data

- In Europe, the General Data Protection Regulation (GDPR) is signaling its firm stance on data privacy and security at a time when more people are entrusting their personal data with cloud services and breaches are a daily occurrence.

- The EU Cybersecurity Act introduces an EU-wide cybersecurity certification framework for ICT products, services and processes. Companies doing business in the EU will benefit from having to certify their ICT products, processes and services only once and see their certificates recognized across the European Union.

Competitive Landscape:

In the chemical industry, companies are adopting advanced technologies like IoT and AI to improve real-time access to critical data and streamline customer interactions.

These solutions enable seamless communication, accurate monitoring, and automation, improvingefficiency, safety, and compliance. Integrating IoT with AI platforms offers a comprehensive approach to optimize production, reduce costs, and improve overall service delivery

-

In September 2023, P360 launched a generative AI-powered platform for life sciences, enhancing real-time product information. In the chemical market, particularly in pharmaceuticals, IoT integration with AI platforms like this drives efficiency, data accuracy, and improved customer engagement.

Key Companies in IoT in Chemical Market:

- Siemens

- Endress+Hauser Group Services AG

- ABB

- Rockwell Automation Inc

- Emerson Electric Co.

- Yokogawa Electric Corporation

- Honeywell International Inc

- Schneider Electric

- Open Automation Software, Inc.

- Microsoft

- Bayer AG

- AstraZeneca

- Intel Corporation

- SAP

- Evoort Solutions

Recent Developments (Partnership/Launch)

- In April 2024, ABB launched the Margo initiative to improve interoperability in Industrial IoT (IIoT) ecosystems. This initiative focuses on increasing efficiency and scalability, particularly in industries like chemicals.

- In September 2024, Schneider Electric partnered with GR3N to improve plastic recycling, focusing on PET (Polyethylene Terephthalate) recycling. This collaboration aims to make hard-to-recycle plastics reusable through GR3N's Microwave Assisted DEpolymerization technology. Aditionally, Schneider Electric's software-driven automation system will help scale this solution and increase its operational flexibility.