Rotary Kiln Market Size

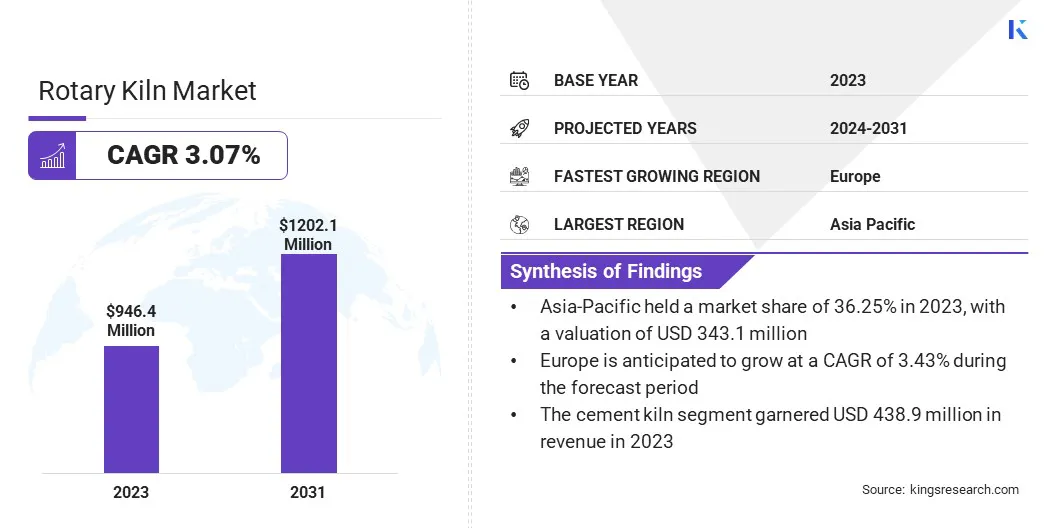

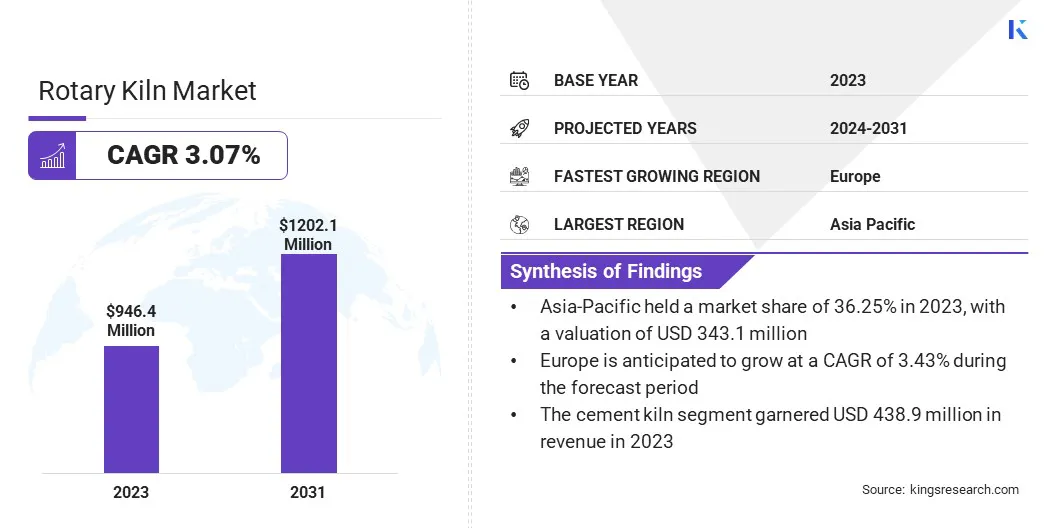

The global Rotary Kiln Market size was valued at USD 946.4 million in 2023 and is projected to grow from USD 972.5 million in 2024 to USD 1,202.1 million by 2031, exhibiting a CAGR of 3.07% during the forecast period. The growth of the market is primarily driven by the increasing demand for cement and lime in construction, rapid urbanization, infrastructure development, the pressing need for energy-efficient production processes, and continual advancements in kiln technologies.

In the scope of work, the report includes products offered by companies such as Jiangsu Pengfei Group Co.,Ltd., Kawasaki Heavy Industries, Ltd., Shanghai Minggong Heavy Equipment Co., Ltd., Sinoma International Engineering Co., Ltd., CITIC Heavy Industries Co., Ltd., FEECO International, Inc., FLSmidth, IHI Corporation, LAFARGE, LNV Technology Pvt Ltd, and others.

The rising demand for cement and lime, which are essential materials in the construction industry, is a key factor bolstering the growth of the rotary kiln market. Rapid urbanization and infrastructure development in emerging economies are significantly boosting this demand. Additionally, the growing need for energy-efficient and environmentally friendly production processes is prompting manufacturers to adopt advanced rotary kiln technologies.

- For instance, in January 2024, JSW Group partnered with Finland’s Coolbrook to implement Coolbrook’s RotoDynamic Heater Technology at JSW’s Vijayanagar Works in Karnataka. This partnership followed successful pilot tests in the Netherlands, showcasing the technology's ability to achieve high temperatures that is crucial for steel production, while reducing carbon dioxide emissions. This significantly advanced JSW's decarbonization efforts in steel and cement manufacturing.

The growing emphasis on recycling and waste management further propels the expansion of the market, as rotary kilns are increasingly used for waste incineration and material recovery. Furthermore, advancements in kiln technologies, such as improved heat transfer efficiency and reduced operational costs, are attracting significant investments, thereby supporting market growth.

The rotary kiln market is witnessing steady growth due to the increasing applications across various industries, including cement, metallurgy, and waste management. The market is characterized by technological advancements aimed at enhancing operational efficiency and reducing environmental impact.

Major players are investing heavily in research and development to innovate and improve product offerings, which in turn, fosters market competitiveness. The Asia-Pacific region dominates the market, driven by rapid urbanization and industrialization, particularly in India and China.

A rotary kiln is a cylindrical vessel used in various industrial processes, including cement production, lime calcination, and waste incineration. It operates at high temperatures, facilitating chemical reactions and phase changes necessary for material processing. Rotary kilns are essential in industries that require continuous thermal processing of bulk materials.

They consist of a rotating drum, lined with refractory material, ensuring durability and heat retention. The rotation facilitates uniform heating and mixing of materials, optimizing the processing efficiency. These kilns are integral to processes that demand precise temperature control, efficient heat transfer, and the capability to handle a variety of materials, thereby contributing to their widespread adoption.

Analyst’s Review

The rotary kiln market is benefiting from efforts by manufacturers to innovate and improve product offerings. Companies are investing heavily in research and development to enhance kiln efficiency and reduce environmental impact. New products featuring advanced control systems and alternative fuel capabilities, are entering the market, addressing the growing demand for sustainable practices.

- For instance, in December 2023, Shree Cement Limited announced the commissioning of a rotary kiln at its new production facility in Rajasthan, with a capacity of 11,500 tonnes per day. This kiln utilized cutting-edge technology incorporating alternative fuels for energy efficiency. The plant, was estimated to cost approximately USD 42.7 million with an annual capacity of 3.5 million tonnes and further included a 33 MW waste heat recovery power plant.

Manufacturers are focusing on providing comprehensive maintenance and support services to optimize operational performance. Prioritizing technological advancements and expanding a presence in emerging geographies, are key imperatives for sustained growth of the market. Additionally, collaboration with regulatory bodies to develop eco-friendly solutions is likely to be crucial in meeting future industry standards and sustaining market competitiveness.

Rotary Kiln Market Growth Factors

The increasing focus on sustainable and energy-efficient production processes impacts the rotary kiln market. Industries are increasingly prioritizing the reduction of carbon emissions and energy consumption. They are being upgraded with advanced technologies, such as improved heat recovery systems and alternative fuel usage, which enhance energy efficiency and reduce environmental impact.

The growing adoption of these sustainable practices is fueling demand for modern rotary kilns, particularly in the cement and lime sectors. This aligns with global environmental regulations and policies, prompting manufacturers to invest heavily in eco-friendly production methods and equipment.

However, the high initial investment and operational costs associated with advanced kiln technologies pose a significant challenge to market development. These costs often present as a barrier for small and medium-sized enterprises (SMEs) seeking to upgrade their equipment. To overcome this challenge, companies are exploring financing options, such as leasing and installment plans, to make their investment more manageable.

Additionally, manufacturers are focusing on developing cost-effective technologies that maintain efficiency without increasing costs. Providing training and support services further helps optimize operational efficiency, thus reducing long-term costs. Collaboration with government initiatives that offer subsidies or incentives for sustainable practices further reduces financial burdens, thereby facilitating broader market adoption.

Rotary Kiln Market Trends

A prominent trend in the rotary kiln market is the increasing integration of digital technologies and automation. Companies are adopting advanced control systems, sensors, and data analytics to enhance kiln performance and efficiency. These technologies enable real-time monitoring and predictive maintenance, thereby reducing downtime and operational costs.

Automation is improving process precision and consistency, leading to higher product quality. The widespread adoption of Industry 4.0 principles, including the Internet of Things (IoT) and machine learning, is transforming traditional kiln operations. This digital shift optimizes production while supporting sustainability efforts by enabling more efficient energy use and lower emissions.

Another key trend in the market is the growing use of alternative fuels and raw materials. Industries are exploring biomass, waste-derived fuels, and other renewable sources to replace conventional fossil fuels. This shift is fueled by the growing need to reduce carbon footprints and comply with stringent environmental regulations.

The use of alternative fuels is both environmentally beneficial and cost-effective, as it often utilizes waste products that would otherwise require disposal. This is promoting the development of rotary kilns capable of handling diverse fuel types, thereby enhancing their versatility and appeal in various industrial applications.

Segmentation Analysis

The global market is segmented based on type, end user, and geography.

By Type

Based on type, the market is categorized into cement kiln, metallurgy kiln, and lime rotary kiln. The cement kiln segment led the rotary kiln market in 2023, reaching a valuation of USD 438.9 million. The demand for cement is rising as urbanization and infrastructure projects proliferate, particularly in developing economies. Cement kilns are essential in producing high-quality cement, meeting the increasing needs of construction activities.

Technological advancements in cement kiln design are enhancing efficiency and reducing emissions, aligning with environmental regulations. Additionally, the industry’s focus on sustainable practices is resulting in the widespread adoption of advanced rotary kilns, thereby boosting the growth of the segment.

By End User

Based on end user, the market is classified construction, minerals & mining, waste management, and others. The construction segment is poised to witness significant growth at a CAGR of 3.62% through the forecast period (2024-2031). This expansion is propelled by the pressing need for infrastructure development worldwide.

Urban expansion, commercial construction, and residential projects are fueling the demand for construction materials, particularly cement and lime produced by rotary kilns. The segmental growth is driven by government investments in public infrastructure and housing.

Additionally, the adoption of sustainable building practices and materials is promoting the use of energy-efficient rotary kilns in construction, thereby supporting this expansion. The ongoing trend towards modernization and urbanization is fostering the development of the segment.

Rotary Kiln Market Regional Analysis

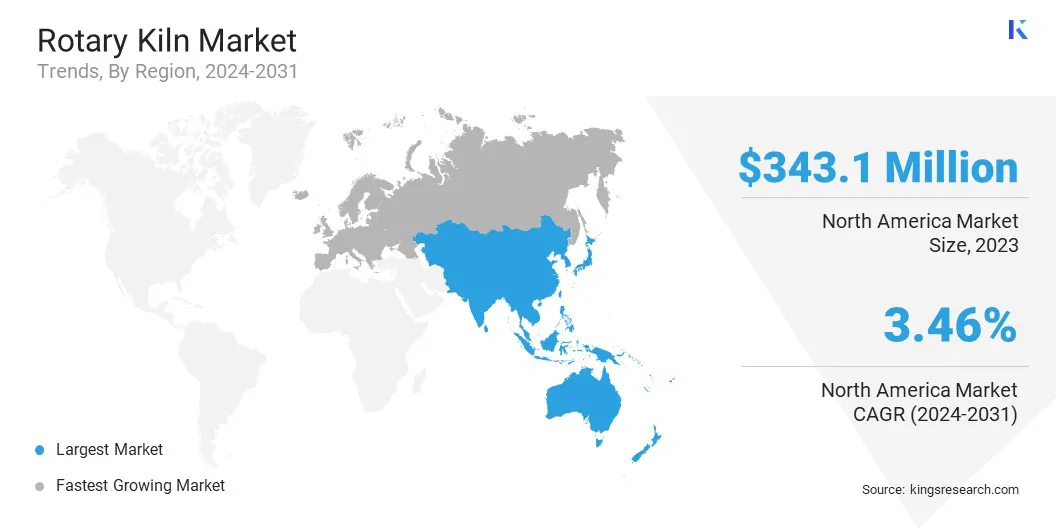

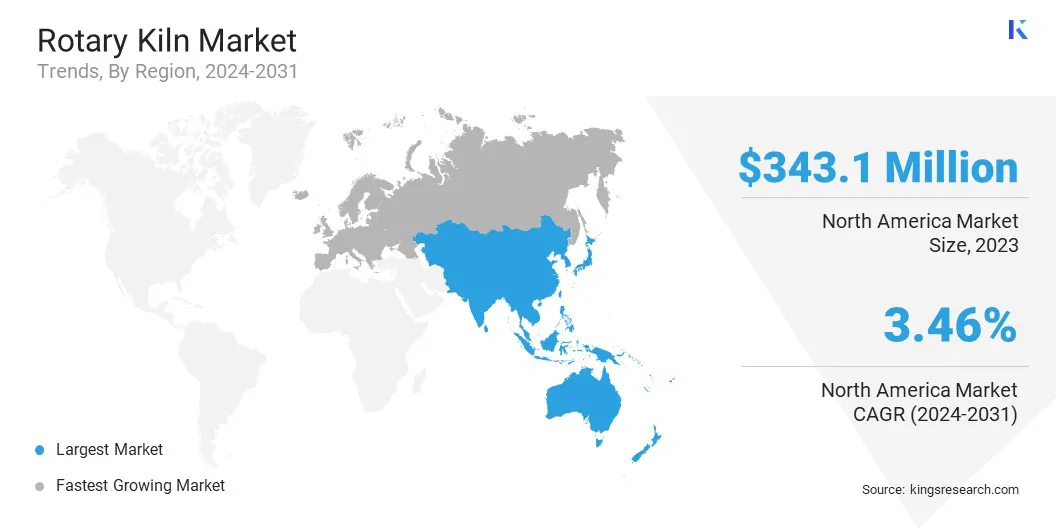

Based on region, the global market is classified into North America, Europe, Asia Pacific, MEA, and Latin America.

Asia-Pacific rotary kiln market share stood around 36.25% in 2023 in the global market, with a valuation of USD 343.1 million. This dominance is reinforced by rapid urbanization and industrialization in countries such as India and China, leading to increased demand for cement and lime. The region’s robust construction industry, fueled by infrastructure development and government investments, is boosting the need for rotary kilns.

Additionally, the presence of key market players and the availability of raw materials at lower costs are enhancing the production capabilities in this region. Technological advancements and the growing adoption of energy-efficient kilns are further supporting domestic market growth.

Europe is poised to experience significant growth at a CAGR of 3.43% over the forecast period. This growth is attributed to stringent environmental regulations, leading to the adoption of energy-efficient and low-emission kilns. The region’s focus on sustainable development and circular economy practices is promoting the use of advanced rotary kilns in waste management and recycling applications.

Additionally, the revival of the construction industry post-economic downturn is increasing the demand for cement and lime. Increased investments in infrastructure projects and technological innovations in kiln operations are contributing to the Europe market expansion.

Competitive Landscape

The global rotary kiln market report will provide valuable insight with an emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions.

Manufacturers are adopting a range of strategic initiatives, including investments in R&D activities, the establishment of new manufacturing facilities, and supply chain optimization, to strengthen their market standing.

List of Key Companies in Rotary Kiln Market

- Jiangsu Pengfei Group Co.,Ltd.

- Kawasaki Heavy Industries, Ltd.

- Shanghai Minggong Heavy Equipment Co., Ltd.

- Sinoma International Engineering Co., Ltd.

- CITIC Heavy Industries Co., Ltd.

- FEECO International, Inc.

- FLSmidth

- IHI Corporation

- LAFARGE

- LNV Technology Pvt Ltd

Key Industry Development

- June 2023 (Launch): Metso launched an electrically powered rotary kiln, the 'RotarEkiln'. This kiln was developed to provide a sustainable alternative to fuel-powered designs. It features modular heating sections that offer superior temperature control and makes maintenance easier. The RotarEkiln is customizable to meet specific performance needs and is designed to achieve kiln shell diameters of up to 5 meters, making it a unique large-scale electric kiln in the market.

The global rotary kiln market is segmented as:

By Type

- Cement Kiln

- Metallurgy Kiln

- Lime Rotary Kiln

By End User

- Construction

- Minerals & Mining

- Waste Management

- Others

By Region

- North America

- Europe

- France

- U.K.

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America