Needle Coke Market Size

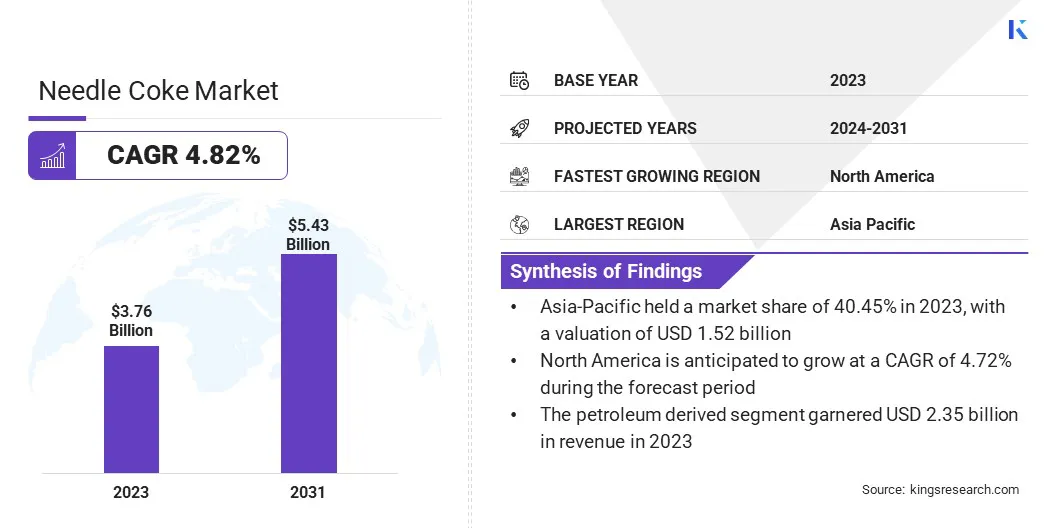

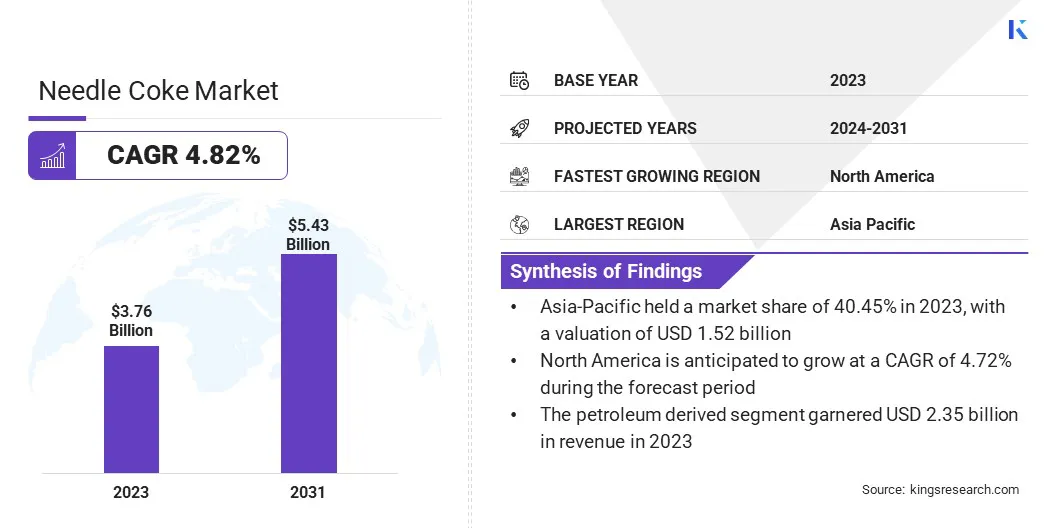

The global Needle Coke Market size was valued at USD 3.76 billion in 2023 and is projected to grow from USD 3.91 billion in 2024 to USD 5.43 billion by 2031, exhibiting a CAGR of 4.82% during the forecast period. The market is evolving with increased interest in renewable energy applications and advancements in aerospace technologies.

As industries seek high-performance materials, needle coke is gaining immense traction due to its superior thermal and electrical conductivity. Emerging applications in specialized coatings and electronics are further contributing to market expansion, reflecting a notable shift toward diversified uses beyond traditional sectors.

In the scope of work, the report includes solutions offered by companies such as China Petroleum & Chemical Corporation, Indian Oil Corporation, Liaoning Baolai Bioenergy Co., Ltd., Mitsubishi Chemical Group Corporation., Nippon Steel Corporation, Phillips 66, Posco Mc Materials, GrafTech International, Shandong Dongyang Technology Co. Ltd, Shandong Yida New Materials Co. Ltd, and others.

The needle coke market is experiencing robust growth, driven by its critical applications in the production of graphite electrodes for steel manufacturing and anodes for lithium-ion batteries. As global steel production expands, especially in emerging economies, the demand for high-quality needle coke is rising. Moreover, the increasing adoption of electric vehicles and consumer electronics is fueling the need for lithium-ion batteries, thereby propelling the demand for needle coke.

- According to the International Energy Agency, the demand for automotive lithium-ion (Li-ion) battery increased by about 65%, reaching 550 GWh in 2022 compared to around 330 GWh in 2021,. This increase is primarily attributed to the growth in electric passenger car sales, with new registrations surging by 55% in 2022 relative to the previous year.

Innovations in refining techniques are enhancing production efficiency and product quality, making needle coke more accessible and cost-effective. These factors, combined with strategic acquisitions and investments, are positioning the needle coke market for sustained expansion.

Needle coke is a specialized form of petroleum coke used primarily in the production of graphite electrodes for electric arc furnaces (EAFs) and as a material for lithium-ion battery anodes. Characterized by its high purity and exceptional conductivity, needle coke is crucial for high-performance applications.

It undergoes a refining process to enhance its properties, including low thermal expansion and high electrical conductivity. These attributes make it an essential material for industries that require precise and efficient operations, such as steel manufacturing and energy storage solutions. Needle coke's quality directly impacts both the performance and longevity of the products it supports.

Analyst’s Review

The increasing adoption of electric arc furnaces (EAFs) is significantly boosting the demand for graphite electrodes. National policies and incentives that support scrap imports and EAF technology are further fueling this trend.

- In November 2023, JFE Steel, revealed its plans to build a large electric arc furnace (EAF) at its Kurashiki facility, which is set to replace an existing blast furnace by 2027. This move underscores the company's dedication to lowering carbon emissions and supporting global climate goals, with the new EAF projected to reduce annual emissions by 2.6 million tons.

Key players are leveraging the growing demand for electric arc furnaces and advancements in steel production by actively investing in innovative needle coke refining technologies and expanding their production capacities. By aligning with global sustainability trends and enhancing product quality, companies are bolstering market growth and gaining a competitive edge.

Needle Coke Market Growth Factors

The ongoing rise in steel production, particularly in emerging economies, is increasing the demand for needle coke. As nations such as China, India, and Brazil continue to industrialize and expand their infrastructure, the demand for high-quality steel is rapidly increasing. Needle coke, a critical component in the manufacturing of graphite electrodes, is essential for steel production via electric arc furnaces. These graphite electrodes, which are pivotal in melting scrap steel and producing new steel products, rely on needle coke's superior properties, such as its low coefficient of thermal expansion and high conductivity.

The expansion of steel production in these rapidly developing regions is propelling the growth of the market. The needle coke market faces significant challenges due to volatile raw material prices, which disrupts production costs and affects profitability. Additionally, stringent environmental regulations necessitate costly investments in cleaner technologies, which place additional strain on financial resources.

Geopolitical tensions and supply chain disruptions further complicate sourcing and distribution, thereby impeding market growth. To counter these challenges, key players are diversifying their raw material sources to minimize supply risks and are investing in advanced technologies to enhance production efficiency. They are further adopting sustainable practices to comply with environmental regulations and exploring new markets to reduce the impact of geopolitical and supply chain issues.

Needle Coke Market Trends

A notable trend influencing the needle coke market is the continuous innovation in production processes, particularly advancements in refining techniques. These technological improvements are enhancing the quality and efficiency of needle coke manufacturing, leading to higher purity levels that meet the stringent requirements of industries such as steel and battery production.

Improved refining methods are increasing yield and reducing production costs, thereby making high-quality needle coke more accessible. Additionally, these innovations are producing needle coke with superior properties, such as higher conductivity and lower thermal expansion. These characteristics are critical for its applications in graphite electrodes and lithium-ion battery anodes, thereby supporting market growth.

The growing adoption of lithium-ion batteries in electric vehicles (EVs) and consumer electronics is creating a strong demand for needle coke, a critical material used in battery anodes. As the shift toward cleaner energy and technological advancement increases, the production of EVs and high-performance electronic devices is expanding rapidly.

Needle coke, known for its high purity and superior conductivity, is essential in manufacturing anodes for lithium-ion batteries. These batteries rely on such anodes to enhance their efficiency and longevity. This surge in demand is prompting manufacturers to enhance their needle coke production and invest in advanced refining processes to meet the rising quality and volume requirements, which is likely to foster market expansion in the forthcoming years.

Segmentation Analysis

The global market is segmented based on type, grade, application, and geography.

By Type

Based on type, the market is categorized into petroleum derived and coal-tar pitch derived. The petroleum derived segment led the needle coke market in 2023, reaching a valuation of USD 2.35 billion. This segment benefits from advancements in refining technologies that enhance the purity and performance of petroleum-derived needle coke, thereby making it suitable for applications in graphite electrodes and lithium-ion batteries.

The increasing demand for electric arc furnace (EAF) steel production and the expansion of the lithium-ion battery market are contributing significantly to the expansion of the segment. Enhanced refining processes and strategic investments are boosting production capacities and meeting rising market needs, thereby augmenting segmental growth.

By Grade

Based on grade, the market is categorized into intermediate, premium, and super premium. The premium segment captured the largest needle coke market share of 45.50% in 2023. This segment focuses on high-purity needle coke, a critical material for the production of high-performance graphite electrodes used in electric arc furnaces (EAFs) and for the manufacturing of high-energy lithium-ion batteries.

The increasing demand for precision and efficiency in steel production and battery technology is propelling the development of the segment. Premium needle coke, characterized by its exceptional thermal stability and electrical conductivity, is crucial for meeting the stringent requirements of nrrdle coke applications.

As industries continue to prioritize performance and reliability, the premium segment is witnessing notable expansion, supported by technological advancements and rising quality standards.

By Application

Based on application, the market is categorized into graphite electrode, special carbon material, lithium ion battery, and others. The graphite electrode segment is expected to garner the highest revenue of USD 2.82 billion by 2031. Graphite electrodes are crucial for producing alloy steel, electric arc furnace steel, various alloys, and nonmetals, due to their ability to generate high temperatures essential for steel refining and smelting processes.

- In December 2023, Graphite India Limited (GIL) allocated approximately USD 6 million to acquire compulsorily convertible preference shares in Godi India Private Ltd., thereby securing a 31% equity stake. Godi India is renowned for its cutting-edge research and development in sustainable batteries and supercapacitor-based energy storage, utilizing environmentally friendly technologies such as Aqueous Electrode Processing and Active Dry Coating. This investment supports GIL’s strategy to enter the advanced battery and energy storage sectors.

These developments are likely to boost the demand for needle coke used in graphite electrodes through the forecast period.

Needle Coke Market Regional Analysis

Based on region, the global market is classified into North America, Europe, Asia-Pacific, MEA, and Latin America.

Asia-Pacific needle coke market share stood around 40.45% in 2023 in the global market, with a valuation of USD 1.52 billion. Rapid industrialization and urbanization are fueling the demand for needle coke, particularly in steel production and battery manufacturing. Significant investments in advanced manufacturing technologies and the growing adoption of electric arc furnaces (EAFs) are stimulating regional market expansion.

India is focusing on reducing carbon emissions by intensifying its decarbonization efforts. There is a rising trend toward adopting EAF technology, which offers a more sustainable alternative to traditional methods. Graphite electrodes are crucial in the EAF process, which is essential for steel production.

According to a report by the Korean Iron & Steel Association, South Korea's steel industry plays a crucial role in the economy, by supporting key sectors such as automotive, construction, and shipbuilding. It contributes 1.5% to the nation's GDP and 4.9% of the country's manufacturing output, positioning South Korea as the sixth-largest steel producer in the world.

North America is anticipated to witness significant growth at a CAGR of 4.72% over the forecast period. This considerable growth is majorly attributed to the growing demand for advanced battery technologies and increasing investments in infrastructure development. The region is focusing on enhancing production capacities and technological innovations to meet the rising needs of the electric vehicle and steel industries. Additionally, favorable government policies and incentives are promoting the adoption of high-performance materials.

- In December 2022, POSCO Chemical signed an agreement with Ultium Cells LLC to supply graphite anode material for expanding EV battery cells in the United States. POSCO Chemical sourced all the material from needle coke, underscoring the region's major focus on advancing battery technologies and enhancing supply chain capabilities for electric vehicles.

The North America market is further benefiting from its robust industrial base and strong research and development capabilities.

Competitive Landscape

The global needle coke market report will provide valuable insight with an emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions.

Companies are implementing impactful strategic initiatives, such as expanding services, investing in research and development (R&D), establishing new service delivery centers, and optimizing their service delivery processes, which are likely to create new opportunities for market growth.

List of Key Companies in Needle Coke Market

- China Petroleum & Chemical Corporation

- Indian Oil Corporation

- Liaoning Baolai Bioenergy Co., Ltd.

- Mitsubishi Chemical Group Corporation.

- Nippon Steel Corporation

- Phillips 66

- Posco Mc Materials

- GrafTech International

- Shandong Dongyang Technology Co. Ltd

- Shandong Yida New Materials Co. Ltd

Key Industry Development

- January 2024 (Product Development): CNPC successfully installed and positioned the top tower for a needle coke facility with a production capacity of 400,000 tons per year at its construction site in Jinzhou, China. The project is anticipated to be completed soon, highlighting the company's commitment to expanding its needle coke production capabilities.

The global needle coke market is segmented as:

By Type

- Petroleum Derived

- Coal-Tar Pitch Derived

By Grade

- Intermediate

- Premium

- Super Premium

By Application

- Graphite Electrode

- Special Carbon Material

- Lithium Ion Battery

- Others

By Region

- North America

- Europe

- France

- U.K.

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America