Market Definition

The market encompasses packaging solutions that incorporate a thin layer of metal, typically aluminum, onto polymer films such as polyethylene (PE), polypropylene (PP), or polyester (PET). This enhances barrier properties against moisture, oxygen, and UV light while maintaining flexibility and lightweight characteristics.

Available in pouches, wraps, and laminates, these materials are widely used in food & beverage, pharmaceuticals, cosmetics, and industrial applications to extend shelf life and improve product protection.

The formulation often involves vacuum metalization, which deposits the metal coating onto the substrate, ensuring cost-effective and efficient packaging with enhanced esthetics and durability.

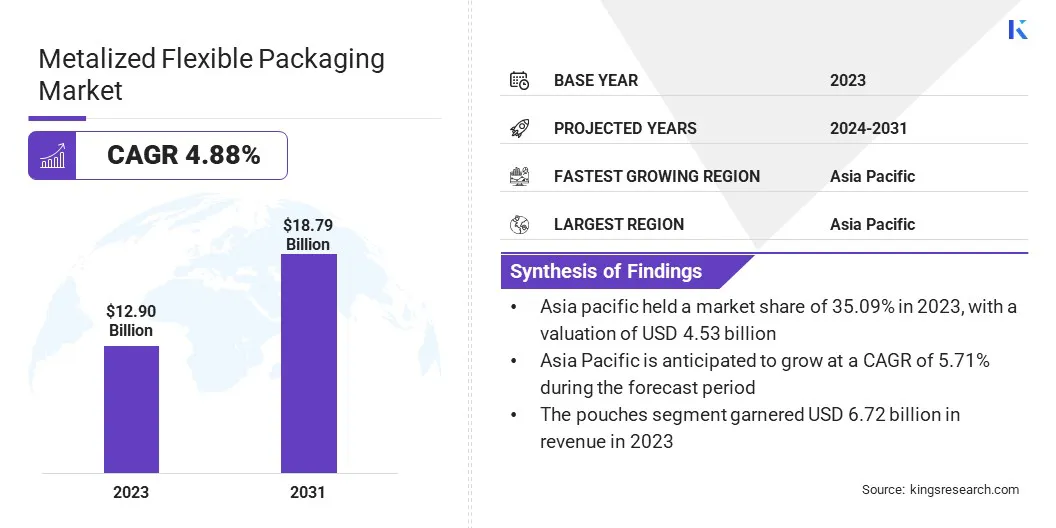

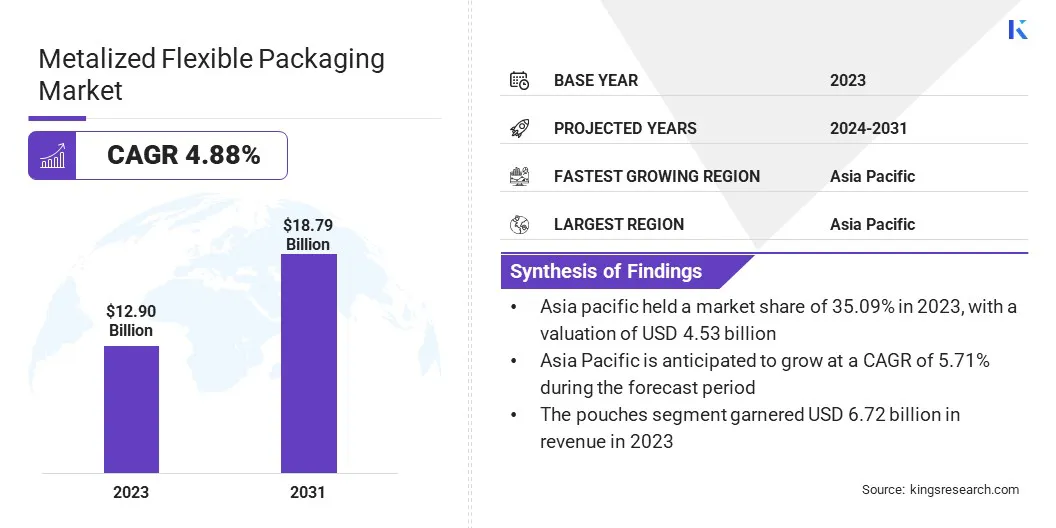

The global metalized flexible packaging market size was valued at USD 12.90 billion in 2023 and is projected to grow from USD 13.46 billion in 2024 to USD 18.79 billion by 2031, exhibiting a CAGR of 4.88% during the forecast period.

The market is driven by the rising demand for lightweight and high-barrier packaging solutions in the food & beverage sector. Increasing consumer preference for sustainable and recyclable packaging materials further accelerates market expansion.

Additionally, advancements in metalized film technology enhance packaging durability and shelf life, making it a preferred choice across various industries, including pharmaceuticals and personal care.

Key Market Highlights:

- The metalized flexible packaging industry size was valued at USD 12.90 billion in 2023.

- The market is projected to grow at a CAGR of 4.88% from 2024 to 2031.

- Asia Pacific held a market share of 35.09% in 2023, with a valuation of USD 4.53 billion.

- The aluminum foil-based segment garnered USD 8.01 billion in revenue in 2023.

- The wraps is poised for a robust CAGR of 7.39% through the forecast period.

- The food and beverages segment is expected to reach USD 13.02 billion by 2031.

- The market in Europe is anticipated to grow at a CAGR of 5.12% during the forecast period.

Major companies operating in the metalized flexible packaging market are Amcor, Constantia Flexibles, Huhtamaki PPL, Sealed Air Corporation, Mondi, Berry Global Group, Toray Industries Inc., Bemis Company, Inc., Glenroy, Inc., Uflex Limited, Polyplex Corporation Ltd., Cosmo Films Ltd., Paramount Global, Inc., Jindal Poly Films Limited, and Innovia Films.

The demand for packaging solutions that enhance product longevity is fueling the market. Industries such as food & beverage, pharmaceuticals, and personal care require high-barrier materials that protect products from moisture, oxygen, and UV light exposure.

Metalized films serve as an effective solution by preventing spoilage and degradation, ensuring longer shelf life and maintaining product integrity. This demand is particularly strong in processed food segments, where freshness and safety are critical factors. The ability of metalized flexible packaging to preserve product quality is driving its adoption, contributing to market expansion globally.

- In July 2024, AkzoNobel introduced the Securshield 500 series, building on the recent launch of Accelshield 700, a styrene-free and BPXni internal coating for beverage can ends. This follows the debut of Accelstyle 100 and 200 overprint varnishes for two-piece aluminum beverage cans, formulated without bisphenols, styrene, and PFAS.

Expanding Processed and Packaged Food Industry

The rapid expansion of the processed and packaged food industry is driving the metalized flexible packaging market. Consumers are shifting toward ready-to-eat meals, snacks, and frozen foods that require advanced packaging solutions to maintain freshness and prevent contamination.

Metalized flexible packaging enhances food safety by providing superior barrier protection, ensuring extended shelf life, and preserving taste and texture. The increasing presence of packaged food brands in retail and e-commerce channels is further accelerating the adoption of high-performance packaging solutions, contributing to market expansion in both developed and emerging economies.

- In February 2025, TIPA Ltd. introduced an innovative home-compostable metallized high-barrier film designed to enhance sustainable packaging solutions. This advanced material meets the demand for eco-conscious packaging in chips and salty snacks by providing superior durability and functionality in a biodegradable format. Ideal for packaging chips, snacks, granola bars, grains, coffee, and tea, the film ensures excellent product freshness and extended shelf life while supporting environmentally friendly disposal.

Regulatory Compliance and Environmental Concerns

Environmental regulations and sustainability mandates pose a significant challenge to the growth of the metalized flexible packaging market. Governments are enforcing stricter recycling policies and restrictions on plastic waste, increasing compliance costs for manufacturers.

Several companies are investing in eco-friendly alternatives, such as recyclable and biodegradable metalized films. Strategic collaborations with sustainable packaging producers and advancements in solvent-free and water-based coatings are also helping manufacturers align with regulatory standards.

Additionally, firms are adopting circular economy practices, including closed-loop recycling systems, to minimize environmental impact and enhance the sustainability of metalized flexible packaging solutions.

Rising Adoption of Flexible Packaging Across Diverse Industries

The increasing preference for flexible packaging solutions is driving the metalized flexible packaging market. Businesses across industries are shifting toward flexible packaging formats, due to their lightweight nature, durability, and ability to extend product shelf life.

Compared to traditional rigid packaging, flexible materials offer enhanced convenience, improved storage efficiency, and reduced transportation costs. Sectors such as food & beverage, personal care, pharmaceuticals, and pet food are registering a surge in demand for flexible packaging, boosting the adoption of metalized films.

The demand for high-performance flexible packaging solutions continues to expand globally as companies focus on innovation and sustainability.

- According to the Flexible Packaging Association report, as of September 2023, the U.S. flexible packaging industry generated USD 41.5 billion in sales. It represents the second-largest segment in the country's packaging sector, accounting for approximately 21% of the USD 180.3 billion U.S. packaging market. Exports contribute nearly 9% of the total flexible packaging shipments in the U.S.

|

Segmentation

|

Details

|

|

By Material Type

|

Aluminum Foil-based , Metalized Film Flexible Packaging,

|

|

By Product Type

|

Pouches, Bags, Wraps, Rollstock

|

|

By Application

|

Food and Beverages, Pharmaceuticals, Personal Care, Others

|

|

By Region

|

North America: U.S., Canada, Mexico

|

|

Europe: France, UK, Spain, Germany, Italy, Russia, Rest of Europe

|

|

Asia-Pacific: China, Japan, India, Australia, ASEAN, South Korea, Rest of Asia-Pacific

|

|

Middle East & Africa: Turkey, UAE, Saudi Arabia, South Africa, Rest of Middle East & Africa

|

|

South America: Brazil, Argentina, Rest of South America

|

Market Segmentation

- By Material Type (Aluminum Foil-based and Metalized Film Flexible Packaging): The aluminum foil-based segment earned USD 8.01 billion in 2023, due to its superior barrier properties against moisture, oxygen, and light, ensuring extended shelf life for food, pharmaceuticals, and consumer goods while meeting stringent packaging regulations and sustainability requirements.

- By Product Type (Pouches, Bags, Wraps, and Rollstock): The pouches segment held 52.09% share of the market in 2023, due to its superior barrier properties, lightweight design, and growing adoption across food, beverage, and pharmaceutical industries for enhanced product protection, extended shelf life, and cost-efficient transportation.

- By Application (Food and Beverages, Pharmaceuticals, Personal Care, and Others): The food and beverages segment is projected to reach USD 13.02 billion by 2031, owing to the growing demand for extended shelf life, superior barrier properties against moisture and oxygen, and lightweight, cost-effective packaging solutions that enhance product freshness and branding appeal.

Based on region, the market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America.

Asia Pacific accounted for a market share of around 35.09% in 2023, with a valuation of USD 4.53 billion. The rapid expansion of e-commerce and organized retail in Asia Pacific is significantly driving the metalized flexible packaging market.

Countries such as China, India, Indonesia, and Vietnam are registering a surge in online shopping, fueled by increasing internet penetration and smartphone adoption.

- According to the 2024 report by the International Trade Association (ITA), India is projected to lead among 20 countries globally in retail e-commerce development from 2023 to 2027, with a CAGR of 14.1%. The top B2C e-commerce segments in the country, ranked in order, include consumer electronics, fashion, furniture, toys and hobbies, biohealth pharmaceuticals, media and entertainment, beverages, and food.

Leading e-commerce platforms, including Alibaba, Shopee, and Flipkart, are driving the demand for durable and lightweight packaging solutions that ensure product safety during transit. The proliferation of hypermarkets and supermarkets in urban centers is further contributing to the demand for premium-quality packaging, accelerating the adoption of metalized flexible packaging in the region.

Additionally, the rapid growth of the pharmaceutical industry in Asia-Pacific is increasing the need for advanced packaging solutions, contributing to the expansion of the market.

Countries such as India and China are among the largest producers and exporters of pharmaceutical products, requiring high-barrier packaging materials to protect sensitive medications from moisture, light, and oxygen exposure. Metalized flexible films offer superior protection for blister packs, sachets, and pouches, ensuring product stability and compliance with stringent pharmaceutical regulations.

The metalized flexible packaging industry in Europe is poised for significant growth at a robust CAGR of 5.12% over the forecast period. The implementation of sustainability regulations across Europe is accelerating the adoption of metalized flexible packaging with recyclable and biodegradable properties.

The European Union’s Single-use Plastics Directive and the Packaging and Packaging Waste Regulation (PPWR) are pushing manufacturers to develop sustainable packaging solutions. Countries such as Germany, France, and the Netherlands have introduced extended producer responsibility (EPR) schemes, requiring companies to reduce plastic waste and increase recyclability.

This regulatory landscape is encouraging packaging manufacturers to invest in recyclable metalized films, promoting sustainable innovations and boosting the market in the region.Furthermore, consumers in countries such as France, Italy, and the UK prioritize high-end packaging that enhances the esthetic appeal of products.

The cosmetics, fragrances, and gourmet food industries rely on metalized flexible films to create visually striking packaging with superior barrier protection. Leading luxury brands are investing in high-performance flexible packaging that aligns with their sustainability commitments while maintaining premium appeal, further driving the market.

Regulatory Frameworks

- In the U.S., the U.S. Food and Drug Administration (FDA) regulates materials intended for food contact under Title 21 of the Code of Federal Regulations (CFR). Manufacturers must ensure that metalized flexible packaging materials comply with these regulations to be deemed safe for food contact. Additionally, the Environmental Protection Agency (EPA) oversees the Resource Conservation and Recovery Act (RCRA), which governs the management of hazardous and non-hazardous solid waste, including packaging materials.

- The EU's Packaging and Packaging Waste Directive (94/62/EC) aims to harmonize national measures concerning the management of packaging and packaging waste to prevent or reduce its impact on the environment. This directive sets essential requirements for the composition and reusable & recoverable nature of packaging, including specific targets for recycling and recovery.

- China's "Law on the Prevention and Control of Environmental Pollution by Solid Wastes" emphasizes the reduction of packaging waste and promotes the use of recyclable materials. The National Food Safety Standard (GB 4806.1-2016) outlines general safety requirements for food-contact materials, applicable to metalized flexible packaging used in food products.

- Japan's "Containers and Packaging Recycling Law" obligates businesses to sort and recycle packaging waste, including metalized materials. The law encourages the development of eco-friendly packaging solutions and mandates clear labeling to facilitate recycling processes.

Competitive Landscape

The metalized flexible packaging market is characterized by several participants, including both established corporations and rising organizations. Market players are engaging in strategic collaborations with sustainable packaging producers to enhance eco-friendly innovations and expand their product portfolios.

These partnerships focus on developing advanced materials, improving recyclability, and meeting regulatory standards. Companies strengthen their competitive edge while addressing the rising demand for sustainable packaging solutions by leveraging shared expertise and resources.

Such initiatives are driving technological advancements and reinforcing sustainability commitments across the industry, significantly contributing to the growth of the market.

- In November 2024, Constantia Flexibles collaborated with Mondelēz International to advance sustainable packaging innovation, focusing on key areas such as aluminum production, heat seal coatings, high-barrier papers, twist films, oriented polyethylene production, and stage-gate innovation.

Key Companies in Metalized Flexible Packaging Market:

- Amcor

- Constantia Flexibles

- Huhtamaki PPL

- Sealed Air Corporation

- Mondi

- Berry Global Group

- Toray Industries Inc.

- Bemis Company, Inc.

- Glenroy, Inc.

- Uflex Limited

- Polyplex Corporation Ltd.

- Cosmo Films Ltd.

- Paramount Global, Inc.

- Jindal Poly Films Limited

- Innovia Films

Recent Developments (M&A/ Product Launch)

- In March 2024, Constantia Flexibles announced the successful acquisition of a majority stake in Aluflexpack AG, a prominent European manufacturer of customized flexible packaging for the food and pharmaceutical industries. This strategic move is expected to enhance Constantia Flexibles' leadership in product innovation and sustainability while expanding its ability to offer a diverse range of packaging solutions to its customers.