Market Definition

The market involves the production and application of magnetic separators, which are devices used to separate magnetic materials from non-magnetic materials. These separators are commonly used in industries like mining and recycling.

The report identifies the principal factors contributing to market expansion, along with an analysis of the competitive landscape influencing its growth trajectory.

Magnetic Separator Market Overview

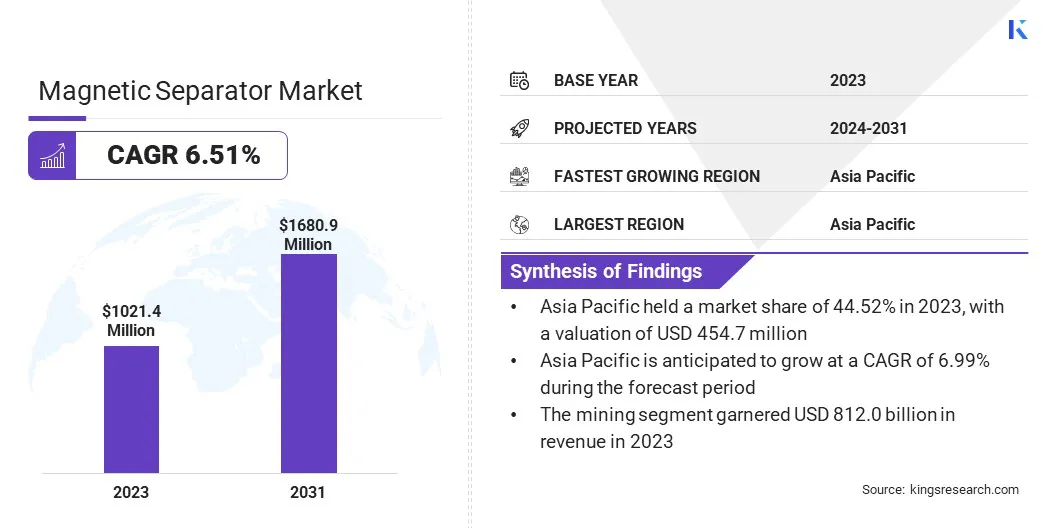

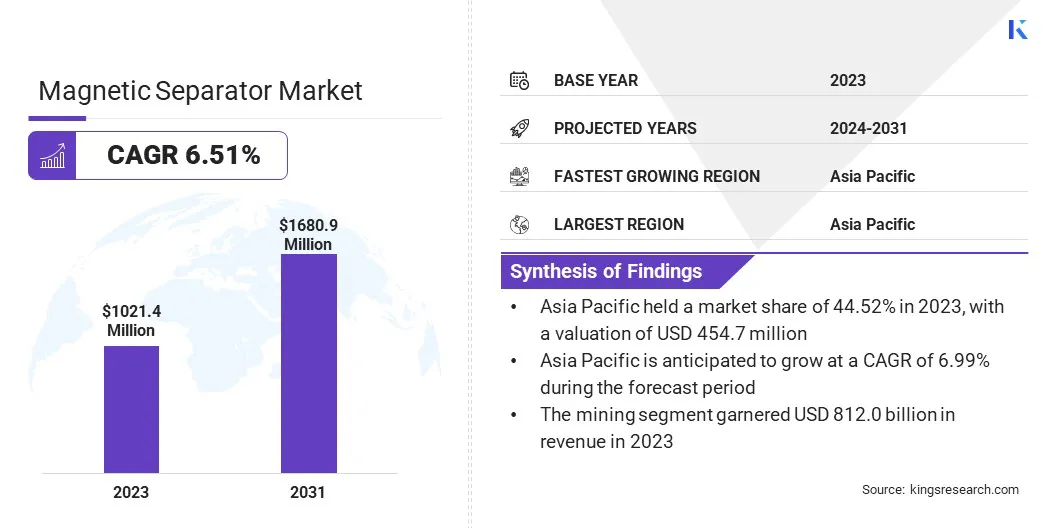

The global magnetic separator market size was valued at USD 1021.4 million in 2023, which is estimated to be USD 1080.7 million in 2024 and reach USD 1680.9 million by 2031, growing at a CAGR of 6.51% from 2024 to 2031. The growing need to protect crushers and machinery from metal contamination is driving the demand for powerful magnetic separators, particularly in industries like mining, recycling, and construction.

Major companies operating in the magnetic separator industry are Eriez Manufacturing Co., Goudsmit Group, Excel Magnetics, Eclipse Magnetics, Metso, Multotec, STEINERT GmbH, LONGi Magnet Co., Ltd., SLon Magnetic Separator Co., Ltd., SOLLAU s.r.o., Shandong Huate Magnet Technology Co.,Ltd, Wagner Magnete GmbH & Co. KG, Permanent Magnets Ltd., Innovative Magnetic Technologies Inc., and ELEKTROMAG DEVICES PVT LTD.

The market is driven by the growing focus on product quality and regulatory compliance across key industries like mining, recycling, and food processing. The market includes a range of products such as magnetic drum separators, magnetic roller separators, overband/cross belt separators, magnetic pulley separators, and eddy current separators.

Advancements in separation technology, along with increased demand for efficient, low-maintenance systems, are fueling adoption. Magnetic separators play a crucial role in enhancing process efficiency, ensuring safety, and supporting sustainable industrial practices.

Key Highlights:

Key Highlights:

- The magnetic separator market size was valued at USD 1021.4 million in 2023.

- The market is projected to grow at a CAGR of 6.51% from 2024 to 2031.

- Asia Pacific held a market share of 44.52% in 2023, with a valuation of USD 454.7 million.

- The magnetic drum separator segment garnered USD 360.3 million in revenue in 2023.

- The high-intensity magnetic separator segment is expected to reach USD 2 million by 2031.

- The mining segment is anticipated to register the fastest CAGR of 6.76% during the forecast period.

- The market in Europe is anticipated to grow at a CAGR of 6.86% during the forecast period.

Market Driver

Increased Demand for Metal Contamination Protection

In industries such as mining and recycling, metal contamination poses a significant risk to crushers and machinery, often leading to costly repairs and downtime. The demand for advanced magnetic separators has surged to prevent damage.

These separators efficiently remove metal parts, safeguarding equipment and ensuring smooth operations. This is a major growth driver for the market, as businesses increasingly rely on these solutions to minimize maintenance costs, enhance productivity, and improve overall equipment longevity in critical industries.

- In January 2025, WAMAG delivered its ultra-powerful overband permanent magnetic separator designed to protect crushers from metal contamination. Installed over a 1,600 mm conveyor with 300 mm material flow, it captures iron objects from remarkable distances, offering superior performance over traditional electromagnets in heavy-duty applications.

Market Challenge

Space and Integration Issues

Space and integration issues pose significant challenges in the magnetic separator market, as installing large separators often requires considerable space and adjustments to existing systems, which can be both costly and complex. Manufacturers are designing more compact, modular magnetic separators that are easier to integrate into various industrial setups.

Additionally, offering tailored solutions and comprehensive installation support helps businesses overcome these hurdles, ensuring smoother integration and reducing operational disruptions, while optimizing space and efficiency within existing facilities.

Market Trend

Automation and Remote Control

The growing adoption of automated systems in the market is a significant trend, as industries seek to improve efficiency and reduce operational costs. Remote monitoring and control capabilities are becoming increasingly common, allowing operators to manage magnetic separators from a distance without constant on-site intervention.

This trend minimizes the need for manual labor, reduces human error, and enhances overall productivity. Integrating automated solutions can help businesses ensure continuous, real-time monitoring, leading to optimized performance, reduced downtime, and more cost-effective operations.

- In October 2024 , MPI launched the Intell-I-Mag magnetic separation mobile app, the first real-time, hands-free tramp metal monitoring system. Accessible via smartphones, the app provides performance alerts, real-time data, and customizable settings, allowing operators to optimize cleaning schedules and reduce downtime, enhancing efficiency and productivity.

Magnetic Separator Market Report Snapshot

|

Segmentation

|

Details

|

|

By Product

|

Magnetic Drum Separator, Magnetic Roller Separator, Over band/Cross Belt Separator, Magnetic Pulley Separator, Eddy Current Separator, Others

|

|

By Intensity

|

High-intensity Magnetic Separator, Wet HIMS, Dry HIMS, Medium-intensity Magnetic Separator , Low-intensity Magnetic Separator

|

|

By Industry

|

Mining, Recycling

|

|

By Region

|

North America: U.S., Canada, Mexico

|

|

Europe: France, UK, Spain, Germany, Italy, Russia, Rest of Europe

|

|

Asia-Pacific: China, Japan, India, Australia, ASEAN, South Korea, Rest of Asia-Pacific

|

|

Middle East & Africa: Turkey, U.A.E., Saudi Arabia, South Africa, Rest of Middle East & Africa

|

|

South America: Brazil, Argentina, Rest of South America

|

Market Segmentation:

- By Product (Magnetic Drum Separator, Magnetic Roller Separator, Over band/Cross Belt Separator, Magnetic Pulley Separator, Eddy Current Separator, Others): The magnetic drum separator segment earned USD 3 million in 2023, due to its high efficiency in removing ferrous materials from bulk materials in various industries.

- By Intensity (High-intensity Magnetic Separator, Wet HIMS, Dry HIMS, Medium-intensity Magnetic Separator, Low-intensity Magnetic Separator): The high-intensity magnetic separator segment held 40.49% share of the market in 2023, due to its superior capability to separate fine and weakly magnetic particles in demanding applications.

- By Industry (Mining, Recycling): The mining segment is projected to reach USD 1361.7 million by 2031, owing to the increasing demand for efficient metal separation and contamination control in mineral extraction and processing.

Magnetic Separator Market Regional Analysis

Based on region, the global market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and South America.

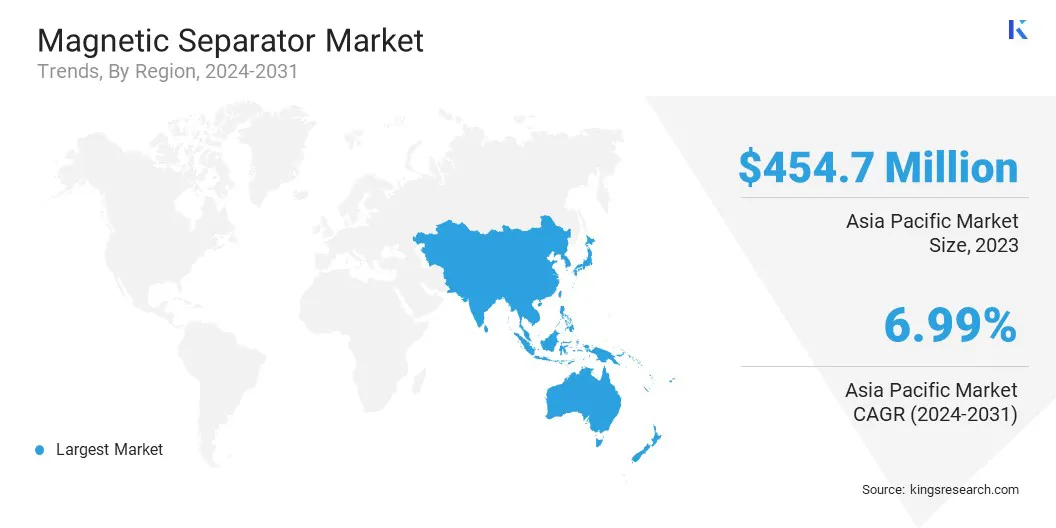

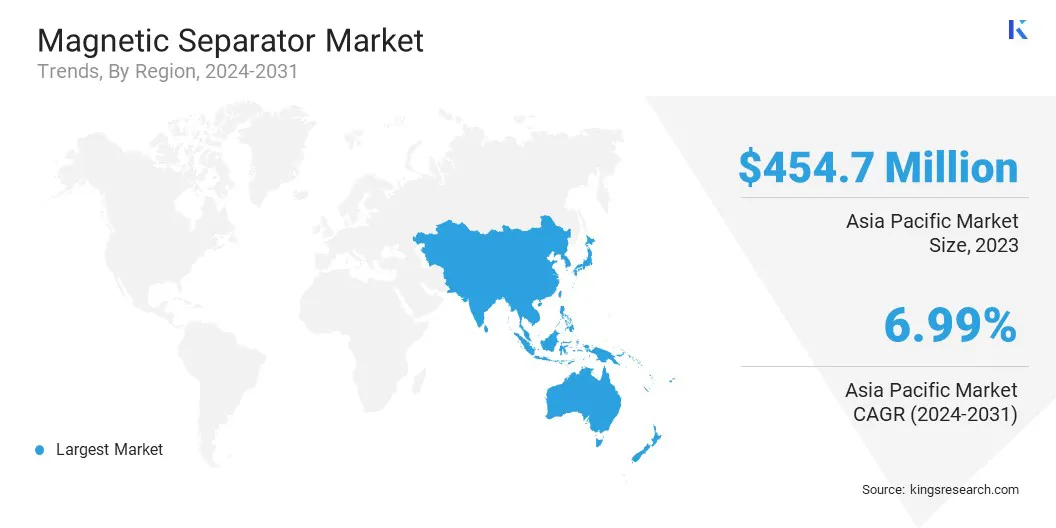

Asia Pacific accounted for a market share of around 44.52% in 2023 in the global market, with a valuation of USD 454.7 million. Asia Pacific dominates the global magnetic separator market, due to rapid industrialization, growing manufacturing sectors, and significant demand for efficient material processing technologies.

Asia Pacific accounted for a market share of around 44.52% in 2023 in the global market, with a valuation of USD 454.7 million. Asia Pacific dominates the global magnetic separator market, due to rapid industrialization, growing manufacturing sectors, and significant demand for efficient material processing technologies.

The region's strong mining and recycling industries, especially in countries like China and India, drive the adoption of magnetic separators. Additionally, the need for advanced separation technologies in food processing, pharmaceuticals, and other sectors contributes to market growth. With increasing environmental regulations and the push for sustainable practices, Asia-Pacific continues to be a key hub for the market's expansion.

The market in Europe is poised for significant growth at a robust CAGR of 6.86% over the forecast period. Europe is rapidly becoming a key growth region for the magnetic separator industry, driven by increasing industrial demands across sectors such as food processing, pharmaceuticals, and recycling.

Stringent regulations on product quality and contamination control are encouraging the adoption of advanced magnetic separation technologies. The need for innovative separation solutions is growing as industries focus on enhancing efficiency, minimizing downtime, and ensuring environmental sustainability. This trend is further supported by significant investments in technology and infrastructure, fueling the market across the region.

- In December 2024, WAMAG successfully showcased its latest magnetic separation solutions at the SYMAS 2024 trade fair in Krakow, Poland. In partnership with MATYKIEWICZ.COM, WAMAG introduced its new small N0 overband permanent separator, receiving significant interest for its effectiveness in removing metal impurities from raw materials in powder and bulk forms.

Regulatory Frameworks

- In India, the Bureau of Indian Standards (BIS) sets guidelines for the manufacturing and performance of magnetic separators, ensuring that they meet quality, safety, and efficiency requirements across various industries.

- In the U.S., the Occupational Safety and Health Administration (OSHA) provides safety standards for equipment used in industries, ensuring the safe handling and operation of machinery, including magnetic separators, to prevent workplace injuries.

Competitive Landscape

Several companies are actively advancing the magnetic separator market by focusing on innovative solutions and technology advancements. These companies are increasingly developing high-performance separators, integrating automation, and enhancing efficiency in diverse industries such as mining, recycling, and food processing.

By leveraging cutting-edge designs, such as improved magnetic materials, intelligent monitoring systems, and environmentally friendly features, businesses aim to meet the growing demands for contamination control, reduce operating costs, and ensure sustainable practices, positioning themselves as leaders in the market's expansion.

- In April 2023, LONGi Magnet Co., Ltd. successfully completed the commissioning of its Magnetic Flotation Separator at a renowned copper mine in South America. This marks the first use of a Chinese magnetic flotation separator for copper tailings in the region. The innovative solution, which operates with low power consumption and eliminates the need for flotation agents, presents a greener alternative to traditional methods, reducing water usage and operating costs while improving the automation of the mining process.

List of Key Companies in Magnetic Separator Market:

- Eriez Manufacturing Co.

- Goudsmit Group

- Excel Magnetics

- Eclipse Magnetics

- Metso

- Multotec

- STEINERT GmbH

- LONGi Magnet Co., Ltd.

- SLon Magnetic Separator Co., Ltd.

- SOLLAU s.r.o.

- Shandong Huate Magnet Technology Co.,Ltd

- Wagner Magnete GmbH & Co. KG

- Permanent Magnets Ltd.

- Innovative Magnetic Technologies Inc.

- ELEKTROMAG DEVICES PVT LTD.

Recent Developments (Product Launch)

- In December 2023, Metso introduced its modular Magnetic Separation Plant Units, designed for high recovery and simplified operations in mining. These units offer easy installation, maintenance, and scalability, ensuring fast setup, high efficiency, and superior recovery of fine and ultrafine particles. Metso’s solutions, including advanced magnetic separation technologies, provide flexible and effective flowsheets for various applications.

Key Highlights:

Key Highlights: Asia Pacific accounted for a market share of around 44.52% in 2023 in the global market, with a valuation of USD 454.7 million. Asia Pacific dominates the global magnetic separator market, due to rapid industrialization, growing manufacturing sectors, and significant demand for efficient material processing technologies.

Asia Pacific accounted for a market share of around 44.52% in 2023 in the global market, with a valuation of USD 454.7 million. Asia Pacific dominates the global magnetic separator market, due to rapid industrialization, growing manufacturing sectors, and significant demand for efficient material processing technologies.