Enquire Now

IoT in Manufacturing Market Size, Share, Growth & Industry Analysis, By Component (Hardware, Software, Services), By Deployment Mode (On-Premises, Cloud-Based), By Application (Predictive Maintenance, Asset Tracking and Management), By Industry Vertical, and Regional Analysis, 2025-2032

Pages: 200 | Base Year: 2024 | Release: October 2025 | Author: Versha V.

Key strategic points

IoT in manufacturing refers to the integration of internet of things (IoT) devices and sensors into manufacturing processes to collect, exchange, and analyze real-time data from industrial equipment and production systems.

It enables smart manufacturing by optimizing operations, enhancing productivity, predicting equipment failures, reducing downtime and supporting data-driven decision-making across the production lifecycle. The market encompasses the development, deployment, and maintenance of connected devices, industrial sensors, software platforms, and network infrastructure.

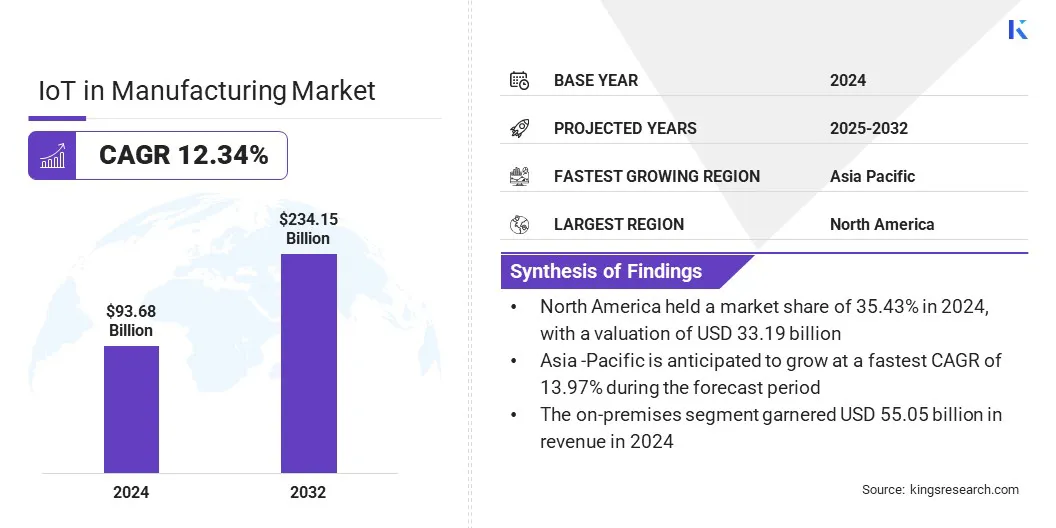

The global IoT in manufacturing market size was valued at USD 93.68 billion in 2024 and is projected to grow from USD 103.71 billion in 2025 to USD 234.15 billion by 2032, exhibiting a CAGR of 12.34% over the forecast period.

This growth is attributed to the expansion of cloud computing and edge analytics capabilities, which are improving real-time data collection, analysis, and decision-making in manufacturing operations. The rising demand for smart manufacturing practices to improve efficiency, productivity, and flexibility in production workflows is further driving the adoption of IoT in manufacturing.

Key Highlights:

Major companies operating in the IoT in manufacturing market are Siemens, Robert Bosch GmbH, ABB Ltd, Schneider Electric SE, Honeywell International Inc., SAP SE, Cisco Systems, Inc., Amazon Web Services, Inc., Microsoft Corporation, IBM Corporation, Rockwell Automation Inc., Telit Cinterion, Advantech Co., Ltd, Wipro Limited, and Ericsson.

Growing investments by market players in IoT in manufacturing is accelerating the adoption of smart and connected factories. Additionally, the expansion of technology development centers to advance IoT solutions is enhancing operational efficiency and real-time monitoring.

Growing Focus on Operational Efficiency and Process Optimization

A major driver in the IoT in manufacturing market is the growing focus on operational efficiency and process optimization. Manufacturers are increasingly adopting IoT-enabled devices, sensors, and advanced analytics to monitor equipment, track production performance, and identify bottlenecks in real time.

This allows companies to reduce downtime, minimize waste, and optimize resource utilization across factories. The rising demand from manufacturers for streamlined operations and data-driven decision-making is prompting investments in connected systems and predictive maintenance technologies.

Data Security and Privacy Concerns

A key challenge in the IoT in manufacturing market is the growing concern over data security and privacy. Connected machines, sensors, and devices can now transmit vast amounts of operational and production data across networks. This rising connectivity exposes manufacturers to cyberattacks, data breaches, and unauthorized access risks, leading to operational disruptions and potential loss of critical intellectual property.

To address this challenge, market players are investing in advanced cybersecurity frameworks, end-to-end encryption, and multi-factor authentication to safeguard industrial data. They are also deploying AI-driven threat detection systems to identify anomalies in real time. Players are also collaborating with IT security providers to design tailored solutions for industrial IoT sector.

Integration of AI and Machine Learning

A notable trend in the IoT in manufacturing market is the growing integration of artificial intelligence (AI) and machine learning (ML) into industrial operations. Manufacturers are deploying AI-driven analytics and ML algorithms to monitor equipment, analyze IoT data, and optimize production workflows.

These technologies are enabling predictive maintenance, real-time anomaly detection, and prescriptive guidance for operators, reducing downtime and operational costs. Companies are adopting AI and ML to enhance decision-making, improve process efficiency, and support smarter manufacturing.

|

Segmentation |

Details |

|

By Component |

Hardware, Software, Services |

|

By Deployment Mode |

On-Premises, Cloud-Based |

|

By Application |

Predictive Maintenance, Asset Tracking and Management, Quality Control, Supply Chain Management, Others |

|

By Industry Vertical |

Automotive, Electronics and Semiconductors, Food and Beverage, Pharmaceuticals, Others |

|

By Region |

North America: U.S., Canada, Mexico |

|

Europe: France, UK, Spain, Germany, Italy, Russia, Rest of Europe |

|

|

Asia-Pacific: China, Japan, India, Australia, ASEAN, South Korea, Rest of Asia-Pacific |

|

|

Middle East & Africa: Turkey, U.A.E., Saudi Arabia, South Africa, Rest of Middle East & Africa |

|

|

South America: Brazil, Argentina, Rest of South America |

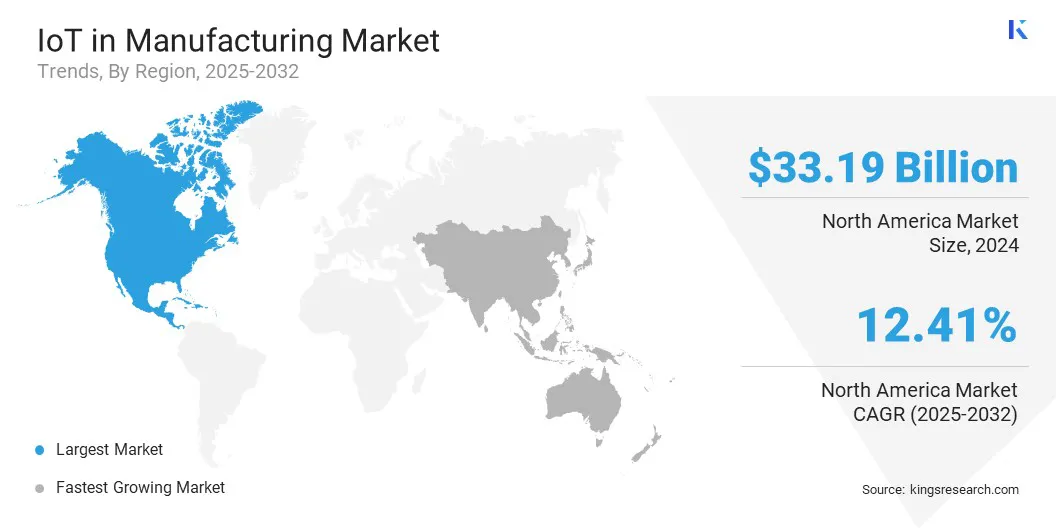

Based on region, the market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and South America.

North America IoT in manufacturing market stood at 35.43% in 2024, valued at USD 33.19 billion in the global market. This dominance is primarily due to the rising adoption of Industry 4.0 technologies, enabling the integration of smart sensors and automation to optimize manufacturing processes. Increasing demand for real-time monitoring and predictive maintenance in manufacturing operations is helping reduce downtime and improve efficiency.

Expansion of cloud computing and edge analytics is supporting seamless data collection, analysis, and decision-making across factories in the region. Additionally, advancements in technologies such as asset-tracking solutions by market players are enhancing operational visibility and optimizing cost efficiency, further driving the expansion of the market.

Asia Pacific IoT in manufacturing industry is set to grow at a robust CAGR of 13.97% over the forecast period, propelled by rapid industrialization and a high demand for smart manufacturing in the region. Expanding investments by governments and regional players in digital infrastructure and automation are enabling the deployment of cost-effective IoT solutions at scale.

Government initiatives, such as South Korea's Smart Factory Initiative and Japan's Society 5.0, aim to integrate IoT, AI, and robotics into manufacturing processes, which is also fueling market growth. Additionally, the integration of connected manufacturing solutions is strengthening production capabilities and supporting the adoption of IoT in manufacturing.

Major players operating in the IoT in manufacturing industry are actively strengthening their competitive position through technological innovation and strategic acquisitions. Key players are investing in research and development to enhance predictive maintenance, real-time monitoring, and AI-driven analytics capabilities.

They are also focusing on expanding their portfolios with wireless IoT devices, secure connectivity platforms, and advanced asset monitoring systems to meet growing demand for smart and connected factories.

Frequently Asked Questions