Market Definition

The hydrogen tank material market involves the production and supply of materials used to manufacture tanks that store hydrogen, crucial for applications such as fuel cell vehicles (FCVs), energy storage, and industrial processes.

Hydrogen tanks are primarily made from lightweight, high-strength materials such as carbon fiber reinforced polymers (CFRP), aluminum and steel alloys designed to withstand the high pressures or cryogenic temperatures required to store hydrogen safely and efficiently.

Hydrogen Tank Material Market Overview

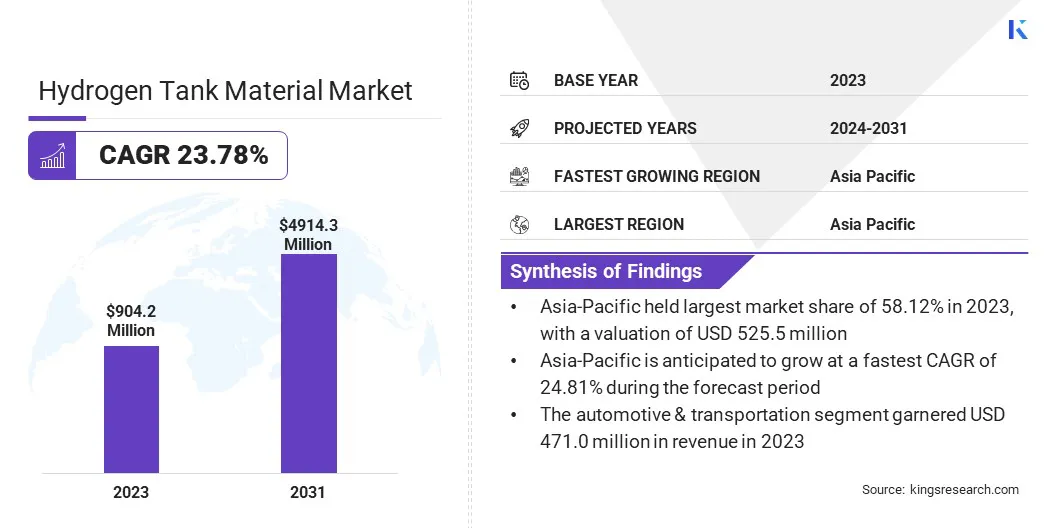

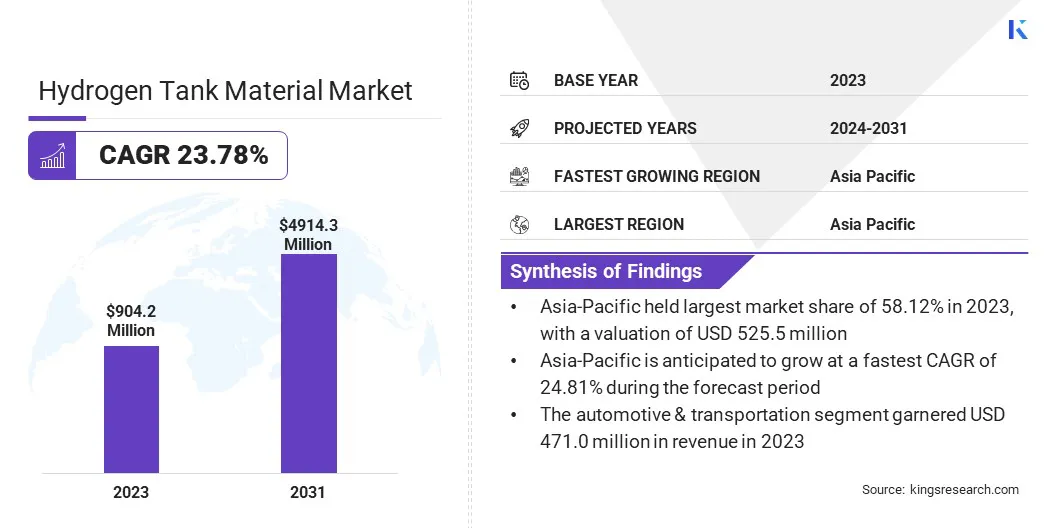

The global hydrogen tank material market size was valued at USD 904.2 million in 2023 and is projected to grow from USD 1,103.6 million in 2024 to USD 4,914.3 million by 2031, exhibiting a CAGR of 23.78% during the forecast period.

This growth is driven by the increasing demand for hydrogen as a clean, sustainable energy source, particularly in sectors like transportation, energy storage, and various industrial processes such as chemical production and manufacturing.

As hydrogen fuel cell vehicles (FCVs) gain popularity and renewable energy projects that require efficient storage solutions continue to grow, the need for reliable and efficient hydrogen storage tanks is surging.

Major companies operating in the global hydrogen tank material industry are BNH Gas Tanks, Acme Process Systems Pvt. Ltd., Quantum Fuel Systems LLC., Didion Vessel, LLC, Hylium Industries, Inc, Doosan Mobility Innovation., DFC Pressure Vessel Manufacturer Co., Ltd, Advanced Structural Technologies, Cryolor, Envalior, Mahytec, ALSAFE COMPANY, CRYOTHERM, Cryofab, Inc., and Taylor-Wharton.

Advances in materials like CFRP and aluminum alloys are making tanks lighter, more durable, and cost-effective, which is further accelerating market growth. Government policies promoting clean energy and growing investments in hydrogen infrastructure are also playing a pivotal role in shaping the market’s future.

- In December 2023, Voith Composites obtained UNECE R 134 certification for its Carbon4Tank, a Type IV hydrogen storage vessel with a capacity of 350 liters and capable of withstanding 700 bar pressure. This certification, governed by the United Nations Economic Commission for Europe, represents the first approval for a hydrogen tank of this size for on-road use, enabling its adoption in heavy-duty trucks and commercial vehicles.

Key Highlights

- The global hydrogen tank material market size was valued at USD 904.2 million in 2023.

- The market is projected to grow at a CAGR of 23.78% from 2024 to 2031.

- Asia-Pacific held a market share of 58.12% in 2023, with a valuation of USD 525.5 million.

- The carbon fiber segment garnered USD 407.7 million in revenue in 2023.

- The type 1 segment is expected to reach USD 2,218.9 million by 2031.

- The chemical segment is anticipated to witness fastest CAGR of 26.97% during the forecast period.

- The market in North America is anticipated to grow at a CAGR of 22.47% during the forecast period.

Market Driver

"Growth of Fuel Cell Vehicles"

Technological advancements in hydrogen fuel cell technology have improved performance, and affordability of FCVs. These vehicles rely on high-pressure tanks made from advanced materials like carbon fiber reinforced polymers (CFRP) and aluminum alloys to store hydrogen 350-700 bar.

FCVs are becoming more viable and appealing, especially for long-distance travel and heavy-duty applications. Unlike battery electric vehicles (BEVs), FCVs offer faster refueling times and longer ranges, making them a better suitedfor specific transportation needs.

Governments around the world are supporting this shift to zero-emission vehicles with supportive policies, subsidies, and investments in hydrogen refueling infrastructure. This growing interest in FCVs is directly driving the need for more advanced and durable hydrogen storage tanks, thus boosting the hydrogen tank material market.

Market Challenge

"Elevated Production Costs of Advanced Materials"

Producing hydrogen storage tanks that meet the required safety standards and performance specifications involves using advanced materials, such as carbon fiber reinforced polymers (CFRP) and high-strength aluminum alloys, which are expensive to produce.

The complexity of manufacturing these materials, along with the need for specialized processes to ensure durability and leak-proof integrity, significantly raises the overall cost of hydrogen tanks.

These high manufacturing costs make it difficult for hydrogen storage systems to be cost-competitive with other alternatives, such as battery electric vehicles (BEVs), particularly in the early stages of market adoption.

Focusing on advancements in material science to develop cost-effective, high-performance materials that maintain safety standards while being less expensive to produce is a key approach. Researchers are exploring alternative composite materials or recycled carbon fiber to reduce the cost of manufacturing.

Improved manufacturing techniques such as automation and more efficient production processes can also help reduce labor and material costs. Collaborations between automakers, material suppliers, and government bodies can facilitate investments in new technologies and innovative solutions that drive down production expenses.

Market Trend

"Advancement in Composite Materials"

Advancements in composite materials especially carbon fiber reinforced polymers (CFRP) are transforming the hydrogen storage tank market. These materials are becoming the go-to choice because they’re lightweight, strong, and corrosion-resistant, which makes them perfect for storing hydrogen at high pressures.

The focus is on improving these materials to make them even more durable, energy-absorbing, and able to handle the extreme conditions hydrogen storage demands. One exciting development is the use of recycled carbon fiber which not only helps lower production costs but also makes the entire process more sustainable.

- In March 2023, SGL Carbon expanded its material portfolio by introducing the SIGRAFIL C T50-4.9/235 carbon fiber, engineered to meet the high-strength requirements of pressure vessel designs.The SIGRAFIL C T50-4.9/235 fiber with higher filament count is particularly suitable for manufacturing high-pressure hydrogen storage tanks.

Hydrogen Tank Material Market Report Snapshot

|

Segmentation

|

Details

|

|

By Material Type

|

Carbon Fiber, Metal, Glass Fiber

|

|

By Tank Type

|

Type 1, Type 2, Type 3, Type 4

|

|

By End-Use Industry

|

Automotive & Transportation, Industrial, Chemicals, Medical & Pharmaceuticals, Others

|

|

By Region

|

North America: U.S., Canada, Mexico

|

|

Europe: France, UK, Spain, Germany, Italy, Russia, Rest of Europe

|

|

Asia-Pacific: China, Japan, India, Australia, ASEAN, South Korea, Rest of Asia-Pacific

|

|

Middle East & Africa: Turkey, UAE, Saudi Arabia, South Africa, Rest of Middle East & Africa

|

|

South America: Brazil, Argentina, Rest of South America

|

Market Segmentation

- By Material Type (Carbon Fiber, Metal, Glass Fiber): The carbon fiber segment earned USD 407.7 million in 2023 due to its lightweight, high-strength properties and increasing demand for high-performance hydrogen storage tanks in fuel cell vehicles and other applications.

- By Tank Type (Type 1, Type 2, Type 3, Type 4): The type 1 segment held 43.09% share of the market in 2023, due to its widespread use in low-pressure applications and affordability, making it a popular choice for smaller-scale hydrogen storage systems.

- By End-Use Industry (Automotive & Transportation, Industrial, Chemicals, Medical & Pharmaceuticals, Others): The automotive & transportation segment is projected to reach USD 2,751.5 million by 2031, owing to the growing adoption of hydrogen fuel cell vehicles and increasing investments in hydrogen infrastructure to support zero-emission transportation solutions.

Hydrogen Tank Material Market Regional Analysis

Based on region, the global market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America.

Asia Pacific hydrogen tank material market share stood around 58.12% in 2023 in the global market, with a valuation of USD 525.5 million. This strong position is due to significant investments in hydrogen infrastructure and the growing popularity of fuel cell vehicles.

Governments in the region are actively supporting clean energy technologies, which has helped boost the adoption of hydrogen solutions across various sectors. There's a rising demand for industrial hydrogen storage and hydrogen-powered heavy-duty vehicles, further driving the market's expansion.

- In October 2023, Toray Industries, Inc., announced TORAYCA T1200, which is the world’s highest strength carbon fiber. This new offering help to shrink environmental footprints by lightening carbon-fiber reinforced plastic materials. T1200 has a tensile strength of up to 1,160 Ksi, more than 10% higher than TORAYCA™ T1100

The hydrogen tank material industry in North America is poised for significant growth at a robust CAGR of 22.47% over the forecast period, driven by increasing investments in renewable energy, government initiatives to reduce carbon emissions, and the growing adoption of hydrogen fuel cells for various applications, including transportation and industrial processes.

As the demand for clean and sustainable energy solutions rises, hydrogen is emerging as a key player in the transition to a low-carbon economy. The need for advanced, lightweight, and durable materials to store hydrogen at high pressures is accelerating innovation in composite materials, metal hydrides, and carbon fiber technologies.

Regulatory Frameworks

- The International Organization for Standardization (ISO) has established the ISO 19884:2018 standard, which outlines the specifications for the design, materials, and testing of hydrogen storage systems

- In the EU, The European Commission oversees the Pressure Equipment Directive (PED) 2014/68/EU, which sets safety requirements for the design, manufacturing, and testing of pressure equipment

Competitive Landscape

The hydrogen tank material market is shaped by the continuous innovation in material technologies and advancements in hydrogen storage solutions. The market is evolving with a strong emphasis on advanced materials such as carbon fiber reinforced composites, metal hydrides, and nanomaterials, which offer enhanced hydrogen storage capacity, durability, and resistance to hydrogen embrittlement.

The rapid advancements in material science, coupled with the growing global interest in clean energy solutions and decarbonization, are set to drive the market forward, fostering a highly competitive environment.

- In December 2023, FORVIA commenced deliveries of Type IV hydrogen tanks from its mass production facility in Allenjoie, France. This state-of-the-art plant, the first of its kind in Europe and North America, aims to produce 100,000 tanks annually. The facility will serve the automotive, hydrogen distribution, and storage industries across the Europe region

List of Key Companies in Hydrogen Tank Material Market:

- BNH Gas Tanks

- Acme Process Systems Pvt. Ltd.

- Quantum Fuel Systems LLC.

- Didion Vessel, LLC

- Hylium Industries, Inc

- Doosan Mobility Innovation.

- DFC Pressure Vessel Manufacturer Co., Ltd

- Advanced Structural Technologies

- Cryolor

- Envalior

- Mahytec

- ALSAFE COMPANY

- CRYOTHERM

- Cryofab, Inc.

- Taylor-Wharton.

Recent Developments (M&A/Partnerships/Agreements/New Product Launch)

- In May 2023, Quantum Fuel Systems introduced its new hydrogen fuel storage system designed specifically for the commercial vehicle industry. The Hydrogen Fuel Storage System is comprised of highly durable, lightweight Type 4 hydrogen tanks that have been tested and validated to meet quality and safety standards.

- In April 2023, Advanced Structural Technologies announced the deployment of its H2Max Cylinder, a hydrogen storage solution that powers the fuel cell system for the Wiggins E-Bull forklift. The aluminum liner is forged and flow formed from a solid billet of 6061 aluminum making it superior for heat and impact tolerance for increased safety.