Fruit Sorting Machinery Market size

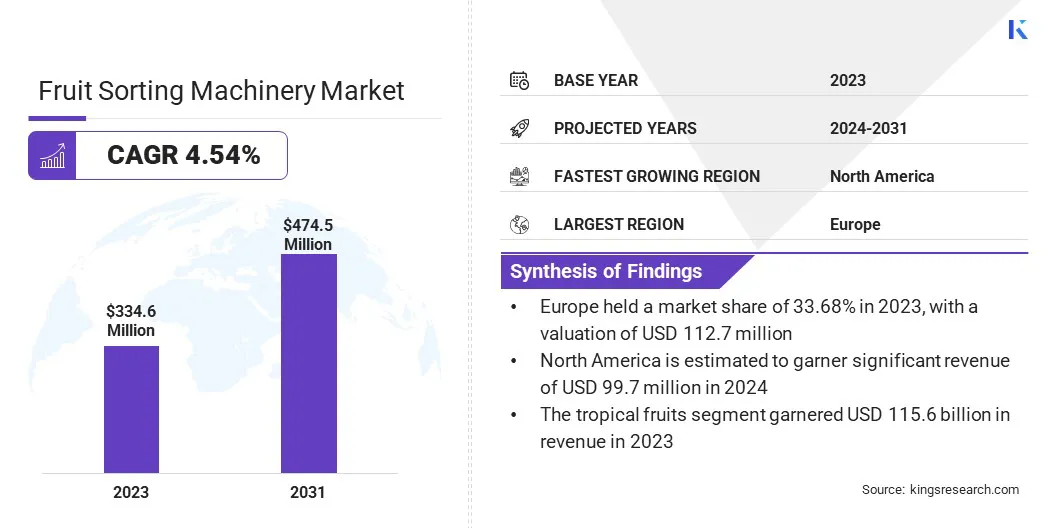

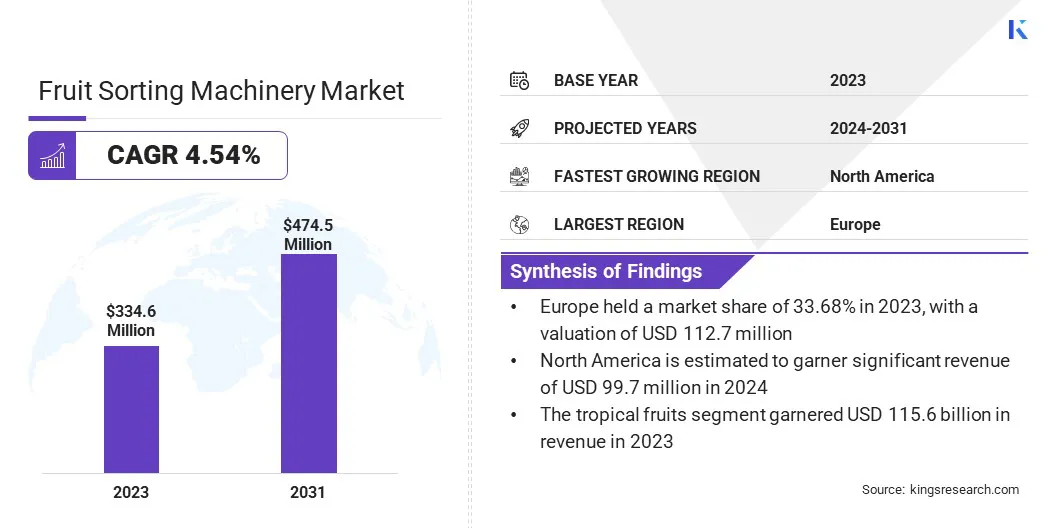

The global Fruit Sorting Machinery Market size was valued at USD 334.6 million in 2023 and is projected to grow from USD 347.9 million in 2024 to USD 474.5 million by 2031, exhibiting a CAGR of 4.54% during the forecast period 2024-2031. In the scope of work, the report includes solutions offered by companies such as Bühler AG, Key Technology, Navatta Group, Bioretics srl, Unitec S.p. A, Anyang General International Co., Ltd., TOMRA Systems ASA, FUTURA SRL, WECO, FENCO Food, and others.

The market is experiencing significant growth, mainly propelled by rapid technological advancements and increasing demand for organic and minimally processed fruits.

Automation and machine learning algorithms have revolutionized fruit sorting processes, thus enhancing efficiency and accuracy. Cutting-edge sorting machinery equipped with advanced sensors and imaging technologies are enabling precise classification based on size, color, shape, and quality of the fruit, thereby meeting the stringent standards of the food industry. This has improved productivity and minimized wastage, thereby reducing operational costs for fruit producers and processors.

Furthermore, the integration of internet of things (IoT) and cloud-based solutions offers capabilities for real-time monitoring and data analytics, facilitating informed decision-making and predictive maintenance. As consumer are increasingly preferring premium quality and consistency, the demand for high-tech fruit sorting machinery is projected to surge, which is presenting lucrative opportunities for market players to innovate and cater to evolving industry needs.

The fruit sorting machinery market encompasses the manufacturing, distribution, and utilization of equipment designed to automate and streamline the sorting and grading processes of various fruits. This market comprises a wide range of sorting machinery, including optical sorters, conveyor systems, and automated grading systems, among others.

The primary objective of these technologies is to enhance efficiency, accuracy, and consistency in fruit sorting operations, thereby optimizing production throughput and ensuring the delivery of high-quality produce to consumers.

Analyst’s Review

The global market is poised to witness significant growth, fueled by several factors such as technological advancements, increasing demand for premium quality produce, and a growing focus on sustainability. Key players in this market are implementing strategies such as product innovation, strategic partnerships, and expansion into emerging markets to strengthen their market presence.

- For instance, TOMRA focuses on developing cutting-edge sorting solutions leveraging AI and machine learning. Bühler emphasizes sustainability by offering eco-friendly sorting technologies. Such strategic initiatives are poised to propel market growth and foster competitive dynamics in the foreseeable future.

Fruit Sorting Machinery Market Growth Factors

The global fruit sorting machinery market is experiencing steady growth, majorly propelled by the rising demand for automation in agriculture due to labor shortages. This is compelling farms to adopt advanced sorting machinery to streamline fruit sorting processes efficiently.

Furthermore, the expansion of organized retail, characterized by supermarkets and grocery chains, is increasing the demand for standardized and consistently graded fruits. This is necessitating the implementation of advanced sorting technology to meet stringent quality requirements and consumer expectations.

Moreover, the growing organic fruit market, with its emphasis on quality and delicate handling, is facilitating market expansion. As organic fruits often have shorter shelf lives, sophisticated sorting systems are essential to minimize fruit damage and ensure product quality. The convergence of these growth factors emphasizes the pivotal role of advanced sorting machinery in meeting the evolving needs of fruit producers, processors, and retailers worldwide, thereby stimulating market expansion and fostering innovation.

However, the high initial investment required for fruit sorting machinery poses a significant barrier to market penetration, particularly for small and medium-scale farmers and businesses. This is deterring potential buyers from investing in advanced sorting technology, which is limiting market reach and widespread adoption.

Manufacturers are considering strategies such as offering financing options or leasing arrangements to mitigate the financial burden on farmers and enhance accessibility to sorting equipment, thereby facilitating market growth.

Fruit Sorting Machinery Market Trends

Growing demand for multi-functional sorting systems capable of sorting items based on various parameters such as size, color, and quality is augmenting the fruit sorting machinery market growth. This trend reflects the pressing need for versatile solutions capable of accommodating the diverse requirements of fruit processors and packers, thus enhancing operational efficiency and product quality.

Furthermore, the increasing demand for customized sorting solutions tailored to the specific needs of different fruits and growers is augmenting the adoption of fruit sorting machines. This trend underscores the importance of flexibility and adaptability in sorting technology, enabling manufacturers to address unique challenges associated with different fruit varieties and production environments.

Moreover, there is an increased focus on sustainability within the industry, leading to the development of energy-efficient sorting machinery with reduced waste generation. As environmental concerns are rising, manufacturers are prioritizing eco-friendly solutions to minimize carbon footprint and resource consumption throughout the sorting process. This emphasis on sustainability is aligning with regulatory requirements and reflecting changing consumer preferences for environmentally responsible practices.

Segmentation Analysis

The global market is segmented based on fruit type, machine type, operation, and geography.

By Fruit Type

Based on fruit type, the fruit sorting machinery market is categorized into citrus fruits, berries, tropical fruits, apple & pears, and others. The tropical fruits segment garnered the highest revenue of USD 115.6 million in 2023. Tropical fruits, such as mangoes, pineapples, and bananas, are increasingly gaining popularity globally due to their unique flavors and nutritional benefits, which is increasing the demand for efficient sorting solutions tailored to their specific characteristics.

Additionally, the perishable nature of tropical fruits necessitates precise sorting processes to maintain product quality and prolong shelf life, underscoring the importance of advanced sorting machinery in this segment.

By Machine Type

Based on machine type, the market is divided into optical sorting machine, weight sorting machine, and others. The optical sorting machine segment captured the largest fruit sorting machinery market share of 54.45% in 2023. Optical sorting machines leverage advanced imaging technologies and artificial intelligence algorithms to accurately assess fruit quality based on color, size, shape, and defects, offering unmatched precision and efficiency in sorting operations.

Additionally, optical sorting machines are highly versatile, and capable of handling various fruit types and sizes with minimal manual intervention, thereby streamlining production processes and reducing labor costs. Moreover, the growing emphasis on food safety and quality assurance contributes to the uptake of optical sorting machines.

These machines enable thorough inspection and detection of contaminants or foreign materials in fruits, thus ensuring compliance with regulatory standards and meeting consumer expectations.

By Operation

Based on operation, the market is bifurcated into automatic and manual. The automatic segment is projected to witness the highest growth, registering a CAGR of 4.69% between 2024 and 2031. Automation offers numerous advantages over manual sorting, including higher efficiency, accuracy, and consistency in sorting processes.

With advancements in technology, automatic sorting machinery precisely classify fruits based on various parameters such as size, color, and quality, reducing human error and enhancing overall productivity.

Additionally, the increasing labor costs and shortage of skilled labor in the agricultural sector boost the adoption of automatic sorting solutions as a cost-effective and sustainable alternative to manual labor. Moreover, automatic sorting systems integrate seamlessly with other automated processes in the production line, thereby optimizing overall operational efficiency and throughput.

Fruit Sorting Machinery Market Regional Analysis

Based on region, the global market is classified into North America, Europe, Asia-Pacific, MEA, and Latin America.

Europe Fruit Sorting Machinery Market share stood around 33.68% in 2023 in the global market, with a valuation of USD 112.7 million. The Europe market is booming due to numerous factors including regulatory compliance, consumer preferences, and technological advancements.

Stringent food safety regulations, similar to those implemented in North America, necessitate precise sorting processes to uphold industry standards and ensure consumer safety. This regulatory environment is resulting in the surge in demand for advanced sorting technologies capable of meeting these stringent requirements.

Furthermore, Europe benefits from the presence of major fruit sorting machinery manufacturers. These manufacturers are leveraging their expertise to develop cutting-edge sorting solutions tailored to the unique needs of European fruit producers and processors. Moreover, sustainability emerges as a significant trend in the region, with a growing emphasis on energy-efficient sorting machinery to minimize environmental impact.

North America is estimated to garner significant revenue of USD 99.7 million in 2024. Stringent food safety regulations are mandating precise sorting processes to ensure compliance and consumer safety. This is necessitating the adoption of advanced sorting technologies capable of meeting these regulatory standards.

Furthermore, the region's major focus on high-quality produce aligns with rising consumer preferences for premium fruits, thereby propelling the demand for sophisticated sorting machinery to maintain product integrity.

Additionally, North America benefits from established automation technologies in the agricultural sector, facilitating the integration of efficient sorting systems into existing production processes. Moreover, the early adoption of artificial intelligence (AI) and machine learning (ML) powered sorting systems positions the region at the forefront of technological innovation in fruit sorting.

Competitive Landscape

The global fruit sorting machinery market report will provide valuable insight with an emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions.

Companies are implementing impactful strategic initiatives, such as expanding services, investing in research and development (R&D), establishing new service delivery centers, and optimizing their service delivery processes, which are likely to create new opportunities for market growth.

List of Key Companies in Fruit Sorting Machinery Market

- Bühler AG

- Key Technology

- Navatta Group

- Bioretics srl

- Unitec S.p. A

- Anyang General International Co., Ltd.

- TOMRA Systems ASA

- FUTURA SRL

- WECO

- FENCO Food

Key Industry Development

- October 2023 (Acquisition): The Maf Roda group acquired Caustier, a renowned Perpignan-based company with a century-long legacy in the arboricultural industry, specializing in summer fruits. This strategic move entails Maf Roda Group sharing its extensive expertise in electronic quality sorting and proficiency in automatic and robotized packaging with Caustier. Through this collaboration, Caustier stands to benefit from Maf Roda Group's advanced technological capabilities and innovative solutions, further enhancing its position in the market and reinforcing its commitment to delivering high-quality products and services to its customers.

The Global Fruit Sorting Machinery Market is Segmented as:

By Fruit Type

- Citrus Fruits

- Berries

- Tropical Fruits

- Apple & Pears

- Others

By Machine Type

- Optical Sorting Machine

- Weight Sorting Machine

- Others

By Operation

By Region

- North America

- Europe

- France

- U.K.

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America