Flow Chemistry Market Size

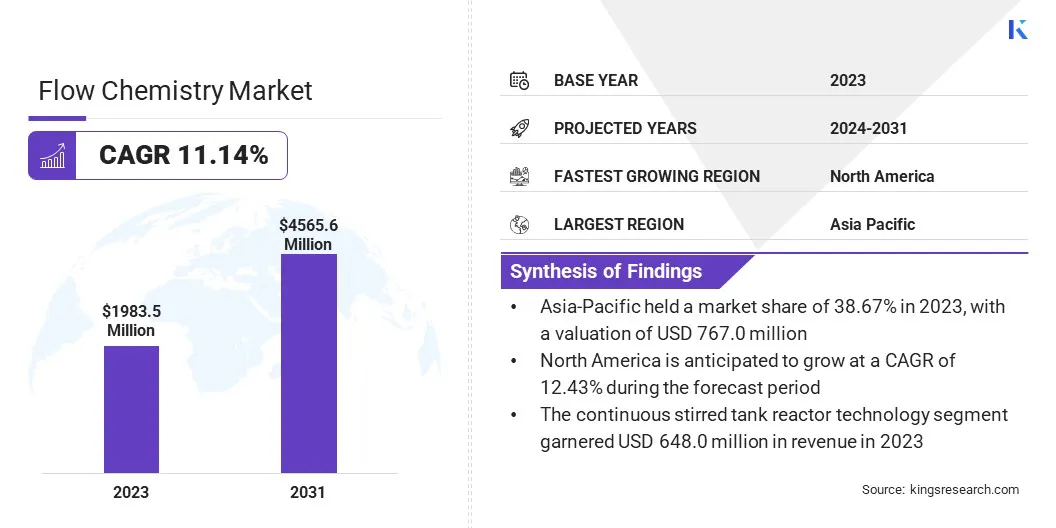

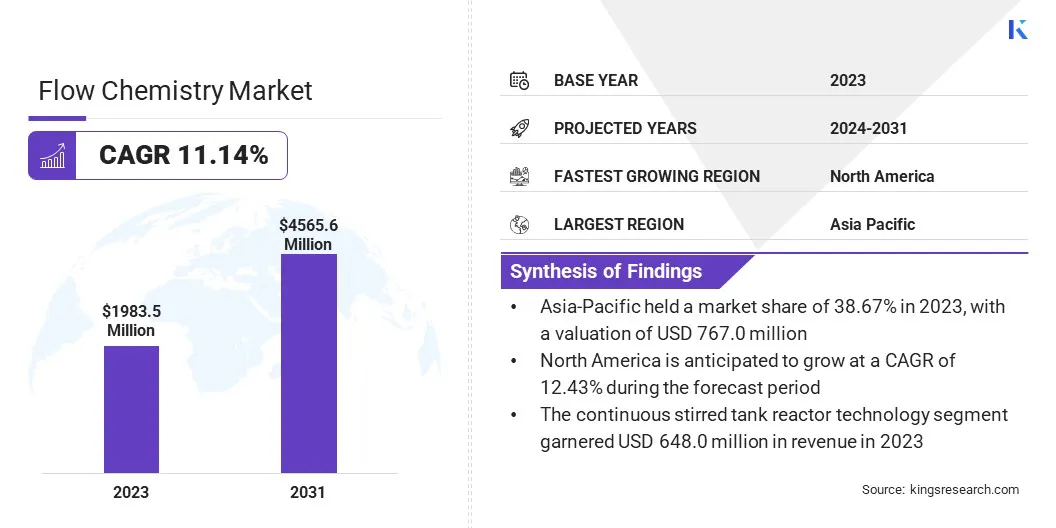

The global Flow Chemistry Market size was valued at USD 1,983.5 million in 2023 and is projected to grow from USD 2,180.2 million in 2024 to USD 4,565.6 million by 2031, exhibiting a CAGR of 11.14% during the forecast period. The market is expanding substantially as industries increasingly adopt continuous processing methods due to their efficiency and precision.

This growth is further fueled by the pressing need for improved reaction control and faster development cycles. Innovations in equipment design and material science are enhancing system robustness and versatility, while regulatory support for cleaner technologies is promoting broader adoption. These factors are collectively boosting advancements and addressing evolving chemical manufacturing needs.

In the scope of work, the report includes solutions offered by companies such as Am Technology, Asahi Glassplant Inc., METTLER TOLEDO, Vapourtec Ltd., ThalesNano Inc., H.E.L. Group, Uniqsis Ltd., Ehrfeld Mikrotechnik BTS, Corning Incorporated, Parr Instrument Company, and others.

The flow chemistry market is experiencing robust growth, mainly driven by advancements in chemical synthesis and increasing demand for sustainable manufacturing practices. Flow chemistry offers significant benefits, including enhanced reaction efficiency, reduced waste, and lower energy consumption compared to traditional batch processes.

- In July 2023, H.E.L Group announced a collaboration with IIT Kanpur to leverage the institute's expertise in sustainable energy. The primary objective of this initiative was to establish new testing labs dedicated to research in new chemistry development, battery storage, and thermal characteristics.

The integration of digital technologies, such as real-time monitoring and control systems, is further optimizing process automation and accuracy. Additionally, the growing trend toward miniaturized and modular systems is enhancing flexibility and scalability for diverse applications. As industries focus on green chemistry and operational efficiency, the flow chemistry market is witnessing substantial expansion, supported by technological innovations and evolving market needs.

Flow chemistry is a method of chemical synthesis in which reactions take place in a continuously flowing stream, as opposed to the traditional batch reactors. This approach involves pumping reactants through a reactor system, which allows for precise control over reaction conditions such as temperature, pressure, and mixing.

The continuous flow enables enhanced reaction efficiency, improved safety, and scalability, making it ideal for both laboratory and industrial applications. Flow chemistry reduces reaction times and by-product formation, while also facilitating easier optimization and scaling of processes. These advantages make it a preferred choice for various chemical industries seeking to improve productivity and process reliability.

Analyst’s Review

The widespread adoption of flow chemistry in chemical manufacturing is fueling market growth by enhancing process efficiency and enabling cost savings. Initiatives like Industry consortium in May 2023 by Imperial and BASF, which focus on making manufacturing more resilient and sustainable, are advancing the capabilities of flow chemistry technologies.

- In January 2023, the partnership between AM Technology and Sterling Pharma Solutions, aimed at advancing AI-driven flow chemistry techniques, has continued to enhance processes and foster innovation.

These advancements lead to more efficient production, reduced operational costs, and the ability to produce customized chemicals, thereby propelling the growth of the market. Key industry players are investing heavily in advanced technologies, forming strategic partnerships, and developing innovative flow chemistry solutions. Emphasizing sustainability, efficiency, and customization in their offerings is anticipated to boost adoption and propel market expansion.

Flow Chemistry Market Growth Factors

The rising emphasis on green chemistry and sustainable manufacturing practices is propelling the growth of the market by offering several key advantages. Flow chemistry reduces waste production through continuous processing, which minimizes by-products and enhances the efficiency of raw material efficiency. It is also operating at lower temperatures and pressures, leading to decreased energy consumption.

These benefits align with the increasing focus on eco-friendly practices, which is boosting the demand for flow chemistry solutions. As industries increasingly prioritize sustainability, the flow chemistry market is expanding, underscoring its importance in advancing greener chemical production and contributing to ongoing market growth.

The high initial investment and capital expenditure required for advanced flow chemistry systems pose a significant barrier to market growth. This financial barrier limits adoption among smaller companies and startups, thereby impeding the dissemination of innovative technologies across various industries.

The expansion of the market is constrained by the challenges associated with accessing and implementing these advanced systems. To address this challenge, key players are focusing on developing cost-effective, modular flow chemistry solutions and providing flexible financing options. They are further investing in research and development to lower technology costs, making advanced flow chemistry more accessible and fostering broader adoption.

Flow Chemistry Market Trends

The integration of digital technologies is emerging as a significant trend in the market, revolutionizing process optimization and automation. Real-time monitoring and control systems are enhancing the precision and efficiency of chemical reactions by providing continuous data on reaction conditions and product quality. These digital tools enable operators to make immediate adjustments, thereby ensuring optimal performance and consistency.

Additionally, advanced analytics and automation facilitate the scaling of processes from laboratory to industrial scale with increased ease and accuracy. As industries seek to improve productivity and reduce operational costs, the adoption of these digital technologies is augmenting the growth of the flow chemistry market.

The rising trend toward miniaturized and modular flow chemistry systems is gaining traction due to their significant advantages in flexibility and scalability. Miniaturized systems, often referred to as microreactors, allow for precise control over reaction conditions on a smaller scale, which is ideal for optimizing processes and conducting high-throughput experiments.

Furthermore, modular systems offer the ability to easily reconfigure and expand reaction setups to accommodate a wide range of chemical processes and applications. This adaptability facilitates seamless transitions from laboratory-scale research to larger industrial-scale production. These systems are enhancing efficiency, reducing costs, and fostering innovation, thereby stimulating the growth of the market.

Segmentation Analysis

The global market is segmented based reactor type, application, and geography.

By Reactor Type

Based on reactor type, the flow chemistry market is categorized into continuous stirred tank reactor, plug flow reactor, micro reactor, packed-bed reactor, photochemical reactor, and others. The continuous stirred tank reactor segment garnered the highest revenue of USD 648.0 million in 2023, owing to its efficient and versatile processing capabilities. CSTRs facilitate continuous operation and allow for precise control over reaction conditions, leading to consistent product quality and higher throughput.

Their ability to handle various reaction types, including exothermic and endothermic processes, makes them highly adaptable to diverse chemical manufacturing needs. Additionally, CSTRs contribute to cost savings by minimizing downtime and reducing waste through efficient mixing and reaction management. As industries seek to optimize production processes and enhance scalability, the adoption of CSTRs is growing.

By Application

Based on application, the market is categorized into pharmaceuticals, chemicals, academia & research, petrochemicals, and others. The chemicals segment captured the largest flow chemistry market share of 43.78% in 2023. Diverse chemical compounds and intermediates are used in various industries, including pharmaceuticals and fine chemicals.

The ability to efficiently produce and manipulate these chemicals using flow chemistry techniques allows for precise control over reaction conditions, which improves product consistency and reduces production costs. Additionally, the growing demand for custom and specialty chemicals, supported by advancements in various sectors, is fostering the adoption of flow chemistry solutions. The broad applicability and efficiency of these chemicals are key factors fueling segmental growth.

Flow Chemistry Market Regional Analysis

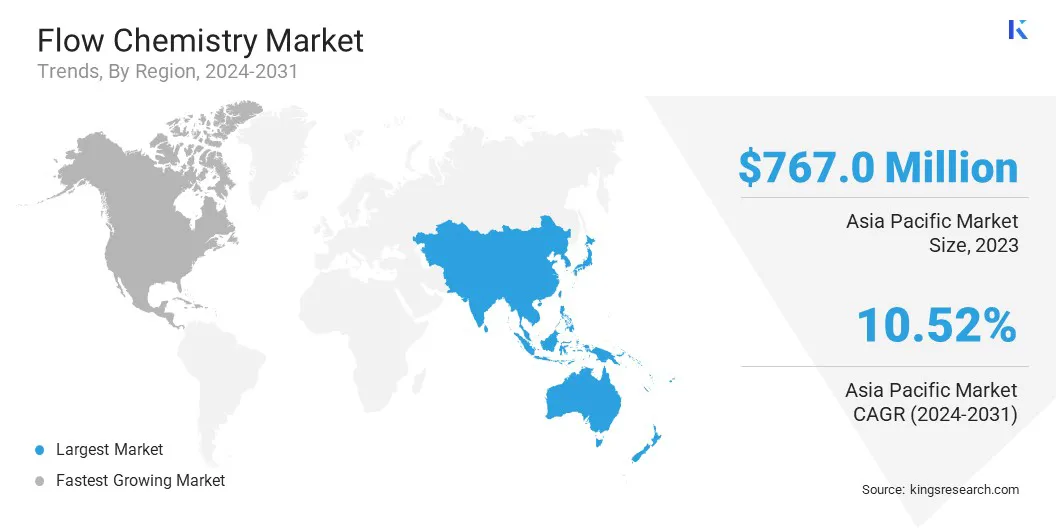

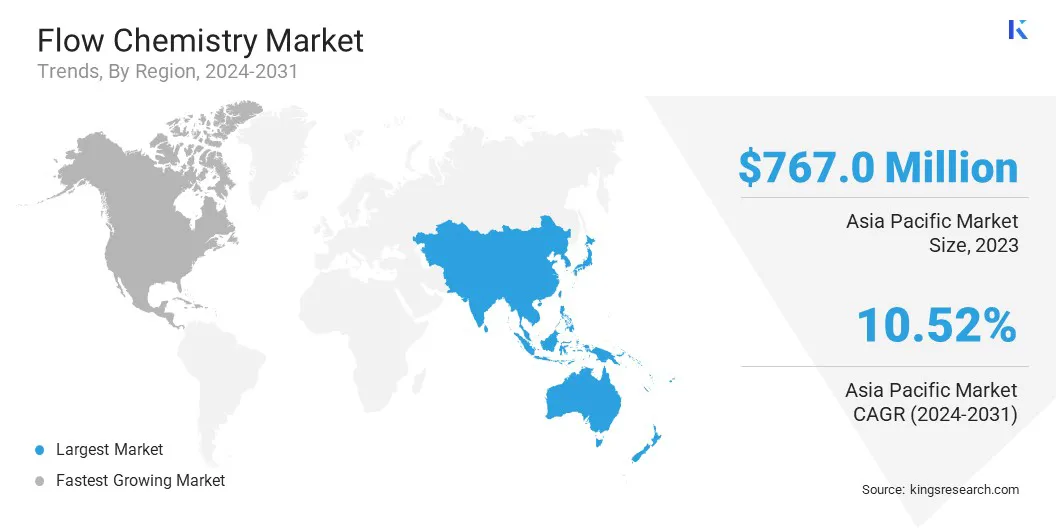

Based on region, the global market is classified into North America, Europe, Asia-Pacific, MEA, and Latin America.

Asia-Pacific flow chemistry market share stood around 38.67% in 2023 in the global market, with a valuation of USD 767.0 million. This notable expansion is attributed to its well-established manufacturing sectors, including chemicals, pharmaceuticals, and petrochemicals. Increased government investment in pharmaceutical production, particularly in response to the rising demand for generic drugs, as well as a favorable outlook for the chemical and petrochemical industries.

China, in particular, is actively investing in expanding its manufacturing capacities to enhance its global trade position, thereby contributing significantly to regional market expansion.

- For instance, in November 2023, Corning Incorporated and Xiamen University established the Xiamen University-Corning Advanced-Flow Reactors (AFR) Application Qualified Lab (AQL) at Xiamen University’s College of Chemistry and Chemical Engineering in Fujian province. This lab enables AFR customers to access continuous-flow demonstrations, conduct experimental trials, perform feasibility testing, and develop chemical reaction processes effectively.

North America is anticipated to witness robust growth, depicting a staggering CAGR of 12.43% over the forecast period. The presence of leading pharmaceutical companies and research institutions boosts the demand for advanced flow chemistry solutions, which offer enhanced efficiency and scalability for drug development and production. The growing focus on personalized medicine and advanced therapeutics is further stimulating the development of the regional market.

Additionally, the region benefits from supportive regulatory frameworks and substantial investments in research and development. For instance, recent collaborations and technology partnerships in the region are facilitating the advancement of flow chemistry applications, reinforcing North America's position as a key region in the global market.

Competitive Landscape

The global flow chemistry market report will provide valuable insight with an emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions.

Companies are implementing impactful strategic initiatives, such as expanding services, investing in research and development (R&D), establishing new service delivery centers, and optimizing their service delivery processes, which are likely to create new opportunities for market growth.

List of Key Companies in Flow Chemistry Market

- Am Technology

- Asahi Glassplant Inc.

- METTLER TOLEDO

- Vapourtec Ltd.

- ThalesNano Inc.

- E.L. Group

- Uniqsis Ltd.

- Ehrfeld Mikrotechnik BTS

- Corning Incorporated

- Parr Instrument Company

Key Industry Development

- January 2024 (Acquisition): AGI Group announced the successful acquisition of Chemtrix B.V., effective December 29, 2023. Chemtrix, a company based in the Netherlands, specialized in designing and manufacturing scalable flow reactors, which enabled both industry and academia to leverage the benefits of flow chemistry and process intensification. This strategic acquisition integrates flow chemistry scale-up capabilities into AGI Group, thereby enhancing their offerings with comprehensive pilot and manufacturing solutions.

The global flow chemistry market is segmented as:

By Reactor Type

- Continuous Stirred Tank Reactor (CSTR)

- Plug Flow Reactor

- Micro Reactor

- Packed-Bed Reactor

- Photochemical Reactor

- Others

By Application

- Pharmaceuticals

- Chemicals

- Academia & Research

- Petrochemicals

- Others

By Region

- North America

- Europe

- France

- U.K.

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America