Market Definition

The market encompasses the manufacturing, distribution, and application of engine belts and hoses across various vehicle types, including passenger cars, commercial vehicles, and Electric Vehicles (EVs). It includes diverse materials such as rubber, silicone, and thermoplastic elastomers (TPE) and serves both traditional and advanced engine systems.

The market operates through OEMs and aftermarket channels, focusing on durability, performance, and regulatory compliance to meet evolving automotive industry demands.

Automotive Engine Belt Hose Market Overview

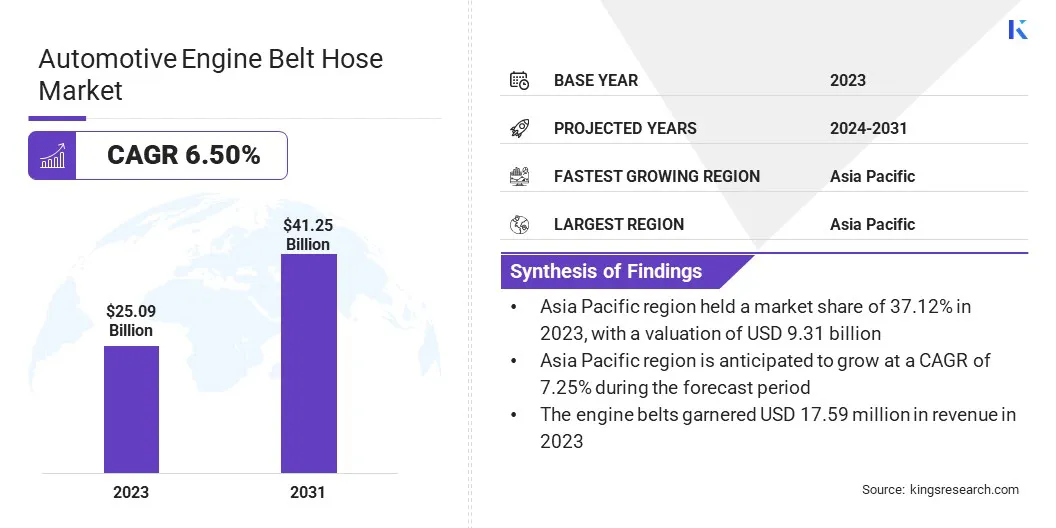

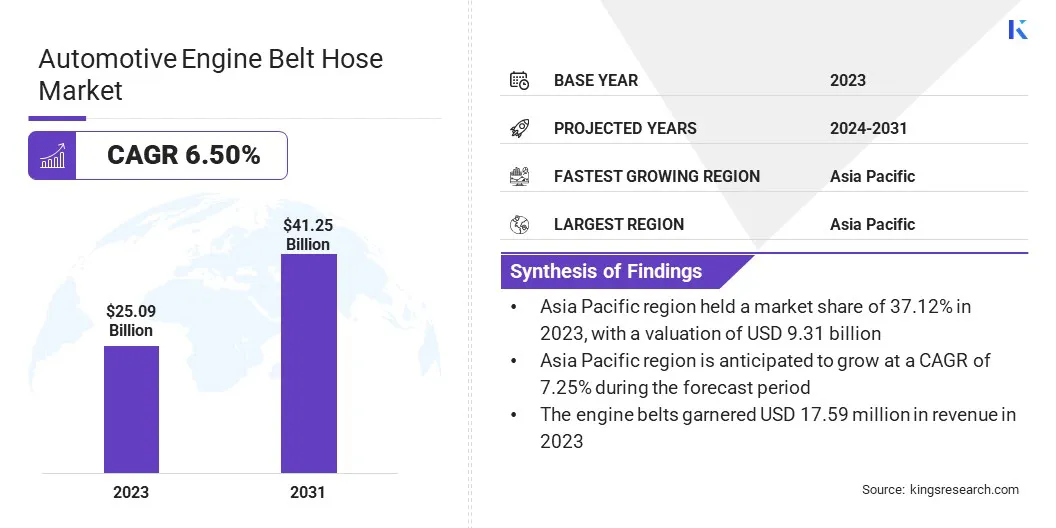

The global automotive engine belt hose market size was valued at USD 25.09 billion in 2023 and is projected to grow from USD 26.55 billion in 2024 to USD 41.25 billion by 2031, exhibiting a CAGR of 6.50% during the forecast period.

This growth is driven by increasing vehicle production, rising demand for fuel-efficient and durable engine components, and advancements in high-performance materials. Automakers are increasingly adopting lightweight rubber, thermoplastic elastomers, and reinforced composites to enhance durability, heat resistance, and flexibility in engine belts and hoses.

Key Market Highlights:

- The automotive engine belt hose industry size was valued at USD 25.09 billion in 2023.

- The market is projected to grow at a CAGR of 6.50% from 2024 to 2031.

- Asia Pacific held a market share of 37.12% in 2023, with a valuation of USD 9.31 billion.

- The engine belts segment garnered USD 17.59 billion in revenue in 2023.

- The rubber segment is expected to reach USD 16.65 billion by 2031.

- The traditional engine systems segment is expected to reach USD 20.91 billion by 2031.

- The passenger cars segment is expected to reach USD 24.70 billion by 2031.

- The Original Equipment Manufacturer (OEM) segment garnered USD 15.58 billion in revenue in 2023.

- The market in Europe is anticipated to grow at a CAGR of 6.40% during the forecast period.

Major companies operating in the automotive engine belt hose market are Regal Rexnord Corporation, Trelleborg Group, Bando USA., Sumitomo Riko Company Limited, ContiTech Deutschland GmbH, Hutchinson, PIX Transmissions Ltd., NTN Group, Mitsuboshi Belting Ltd., Gates Corporation, TSUBAKIMOTO CHAIN CO., Dayco Incorporated, Optibelt GmbH, The Goodyear Tire & Rubber Company, and THE YOKOHAMA RUBBER CO., LTD.

Automakers adopt lightweight, durable materials and high-performance components to drive fuel efficiency, durability, and reduced emissions. Technological innovation, advanced production techniques, and a focus on high-performance solutions are set to deliver competitive advantages and market expansion.

- In May 2024, Belt Power, LLC, a leading distributor and fabricator of lightweight conveyor system components, acquired Avtech Industrial Products. This strategic acquisition enhances Belt Power’s market presence in Phoenix, leveraging Avtech’s expertise in conveyor belts, motors, drives, and industrial solutions. The integration strengthens service capabilities, expands fabrication expertise, and reinforces Belt Power’s commitment to delivering value-added solutions to customers.

Growing Demand for Lightweight and Durable Materials

The automotive engine belt hose market is registering significant growth, driven by the increasing adoption of lightweight, high-performance materials in vehicle manufacturing. Automakers prioritize fuel efficiency and emissions reduction, leading to the widespread use of advanced rubber and polymer composites in engine belts and hoses.

These innovative materials provide superior durability, heat resistance, and flexibility, thereby enhancing the lifespan and reliability of engine components. Manufacturers are investing in state-of-the-art production techniques and sustainable materials to further reduce weight without compromising performance. By continuously optimizing material performance, companies are poised to gain a competitive edge and drive robust growth in the market.

- In July 2024, Dow launched its bio-based NORDREL REN EPDM for the market. Engineered for superior durability and thermal stability, this innovative elastomer enhances performance in engine belts and hoses, supporting sustainability and improved efficiency in next-generation automotive applications.

Volatility in Raw Material Prices

A key challenge in the market is the fluctuation in raw material prices, particularly of rubber and synthetic polymers. The cost of these materials is heavily influenced by global supply chain disruptions, crude oil price fluctuations, and geopolitical tensions.

This volatility directly impacts production costs, leading to pricing pressures on manufacturers. Strategic partnerships with raw material suppliers and the implementation of cost-effective procurement strategies can help stabilize pricing and ensure long-term profitability in the market.

The automotive engine belt hose market is registering a growing demand for high-performance belts and hoses that can withstand extreme temperatures, pressure variations, and prolonged operational stress. Automakers are increasingly focusing on durability, efficiency, and heat resistance to enhance engine performance and longevity.

High-quality materials such as advanced synthetic rubber, reinforced composites, and thermoplastic elastomers are being utilized to improve flexibility, reduce weight, and increase resistance to wear and degradation.

Additionally, the shift toward turbocharged engines and hybrid powertrains has driven the need for hoses and belts with superior thermal stability and vibration resistance. This trend is expected to further accelerate the growth and evolution of the market in the coming years.

- In December 2024, Continental AG launched its innovative X‑LIFE XCP5 engine belt, featuring state-of-the-art materials for enhanced durability, thermal stability, and performance efficiency. This product reinforces Continental's commitment to advancing the market with technology that meets rigorous performance and emissions standards.

Automotive Engine Belt Hose Market Report Snapshot

|

Segmentation

|

Details

|

|

By Product Type

|

Engine Belts, Engine Hoses

|

|

By Material Type

|

Rubber, Silicone, Thermoplastic Elastomers (TPE)

|

|

By Technology

|

Traditional Engine Systems, Advanced Engine Systems

|

|

By Vehicle Type

|

Passenger Cars, Commercial Vehicles, Electric Vehicles

|

|

By Sales Channel

|

Original Equipment Manufacturer (OEM), Aftermarket

|

|

By Region

|

North America: U.S., Canada, Mexico

|

|

Europe: France, UK, Spain, Germany, Italy, Russia, Rest of Europe

|

|

Asia Pacific : China, Japan, India, Australia, ASEAN, South Korea, Rest of Asia Pacific

|

|

Middle East & Africa: Turkey, UAE, Saudi Arabia, South Africa, Rest of Middle East & Africa

|

|

South America: Brazil, Argentina, Rest of South America

|

Market Segmentation:

- By Product Type (Engine Belts, Engine Hoses): The engine belts segment earned USD 17.59 billion in 2023, due to the rising demand for timing belts and serpentine belts in modern engine designs.

- By Material Type (Rubber, Silicone, Thermoplastic Elastomers (TPE)): The rubber segment held 48.12% share of the market in 2023, due to its superior flexibility, cost-effectiveness, and widespread use in both engine belts and hoses.

- By Technology (Traditional Engine Systems, Advanced Engine Systems): The traditional engine systems segment is projected to reach USD 20.91 billion by 2031, owing to the continued dominance of internal combustion engines (ICE) in global vehicle sales.

- By Vehicle Type (Passenger Cars, Commercial Vehicles, Electric Vehicles): The passenger cars segment is projected to reach USD 24.70 billion by 2031, owing to the increasing production and sales of personal vehicles globally.

- By Sales Channel (Original Equipment Manufacturer (OEM), Aftermarket): The Original Equipment Manufacturer (OEM) segment held 62.09% share of the market in 2023, due to strong partnerships between automakers and component suppliers.

Automotive Engine Belt Hose Market Regional Analysis

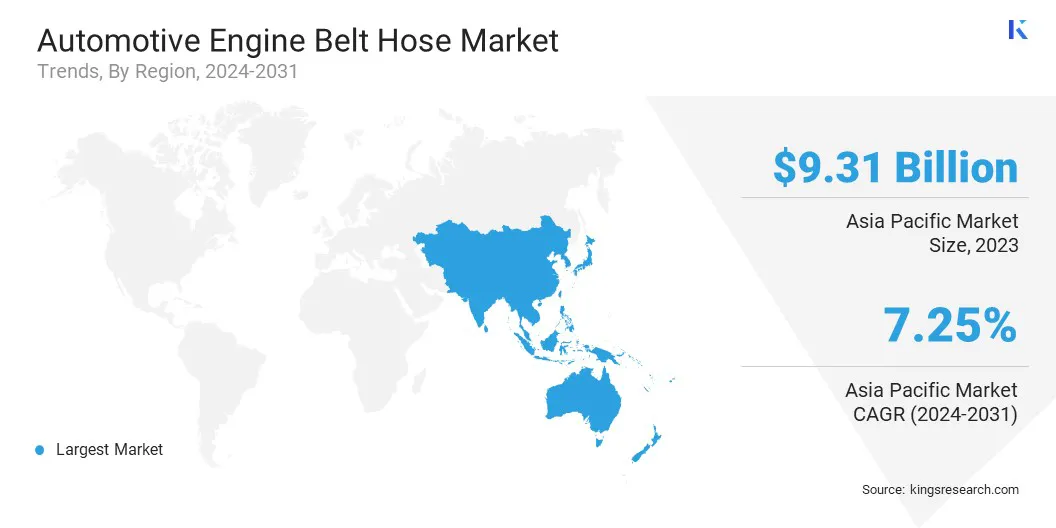

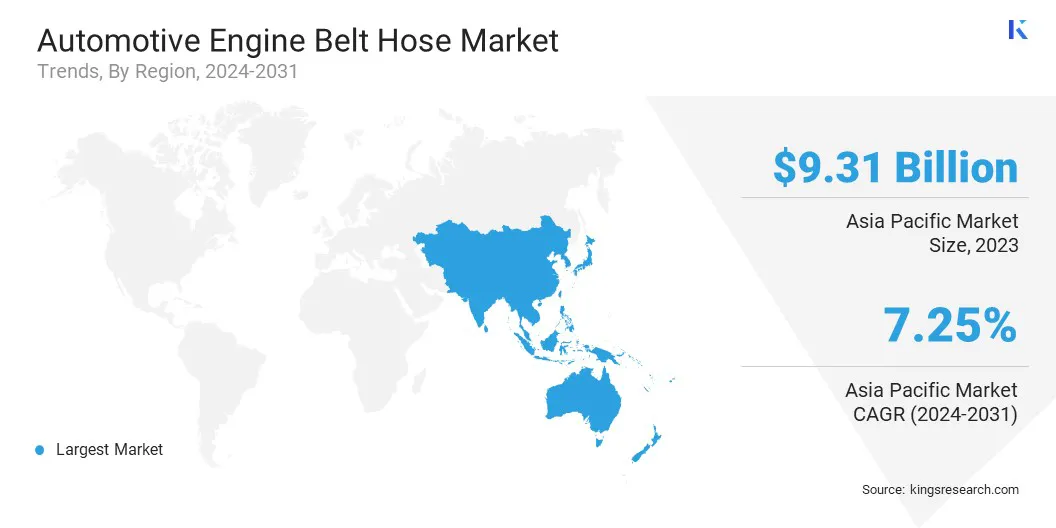

Based on region, the global market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America.

Asia Pacific accounted for 37.12% share of the automotive engine belt hose market in 2023, with a valuation of USD 9.31 billion. The dominance is driven by robust industrial expansion, substantial R&D investments, and supportive government policies that foster innovation.

Rapid growth in automotive manufacturing, particularly in emerging economies like China and India, fuels demand for high-quality, durable engine components. Cost-effective production, combined with a skilled workforce and strategic collaborations with global industry leaders, further enhances market competitiveness.

Additionally, rising consumer preference for fuel-efficient, low-emission vehicles has spurred advancements in material technologies and production processes, positioning the region as a key innovation hub in the market.

The automotive engine belt hose industry in Europe is poised to grow at a significant growth at a CAGR of 6.40% over the forecast period, driven by environmental regulations and an evolving focus on sustainability. The region's mature automotive sector continues to invest heavily in advanced manufacturing technologies and high-performance components.

Manufacturers are leveraging innovative materials and precision engineering to develop engine belts and hoses that meet rigorous emissions and fuel efficiency standards.

Furthermore, the increasing demand for performance-driven solutions and enhanced durability is reinforcing Europe's competitive landscape, positioning the region as a pivotal hub for innovation and growth in the market.

Regulatory Frameworks

- In the U.S, the National Highway Traffic Safety Administration (NHTSA) is a primary regulator enforcing Federal Motor Vehicle Safety Standards. It oversees safety, performance, and compliance of components such as engine belts and hoses, ensuring rigorous industry standards.

- In India, the Ministry of Road Transport and Highways regulates vehicle safety, compliance, and performance standards, while the Bureau of Indian Standards (BIS) sets technical and quality benchmarks for automotive components, including engine belt hoses. Together, they uphold rigorous national safety and quality protocols.

Competitive Landscape:

The automotive engine belt hose industry is characterized by a highly competitive environment dominated by established players with deep industry expertise, diversified product portfolios, and expansive global distribution networks.

These companies invest heavily in advanced manufacturing technologies and R&D, continuously introducing innovative products that meet the evolving demands of modern automotive engines. Their product strategies focus on developing high-performance, lightweight, and durable components that deliver superior reliability and efficiency.

Strategic initiatives such as mergers, acquisitions, and joint ventures are frequently pursued to enhance market penetration and access emerging regional markets. Additionally, a growing commitment to sustainable manufacturing practices and eco-friendly material integration is reshaping product development and competitive positioning.

This focus on quality, efficiency, and customer-centric solutions drives the market and fosters continuous technological innovation, enabling leading companies to capitalize on emerging opportunities in the dynamic market.

- In March 2024, Jason Industrial launched the 4306 MP300 Multi-Purpose NBR Non-Conductive Hose, engineered for the market. This high-performance, oil-resistant hose features a nitrile ARPM Class A tube and cover with four-spiral polyester yarn, delivering reliable non-conductive performance up to 300 PSI.

Key Companies in Automotive Engine Belt Hose Market:

- Regal Rexnord Corporation

- Trelleborg Group

- Bando USA.

- Sumitomo Riko Company Limited

- ContiTech Deutschland GmbH

- Hutchinson

- PIX Transmissions Ltd.

- NTN Group

- Mitsuboshi Belting Ltd.

- Gates Corporation

- TSUBAKIMOTO CHAIN CO.

- Dayco Incorporated

- Optibelt GmbH

- The Goodyear Tire & Rubber Company

- THE YOKOHAMA RUBBER CO., LTD.

Recent Developments (New Product Launch)

- In November 2024, SPIR STAR AG launched its new 10mm Hydrogen Hose, specifically designed for hydrogen-powered vehicles. Engineered for advanced hydrogen applications, it optimizes hydrogen transport in fuel cell systems, enhancing safety and performance while reinforcing SPIR STAR AG’s leadership in the market.

- In January 2024, Gates Corporation launched its new Gates Belt-in-Oil Kits, offering a comprehensive solution with timing belts, metals, bolts, seals, and gaskets to meet OE manufacturer standards and enhance system durability & safety in the market.