Thermoplastic Vulcanizates Market size

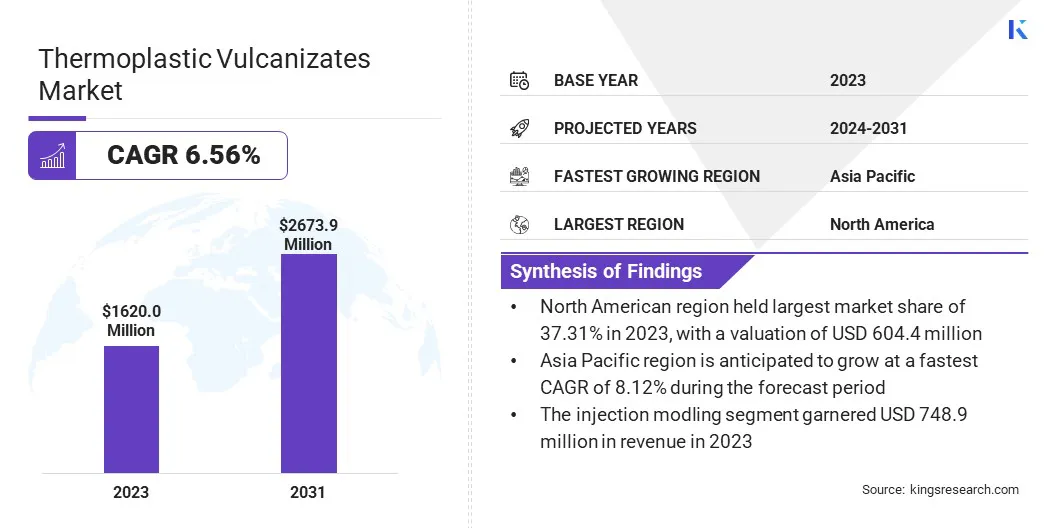

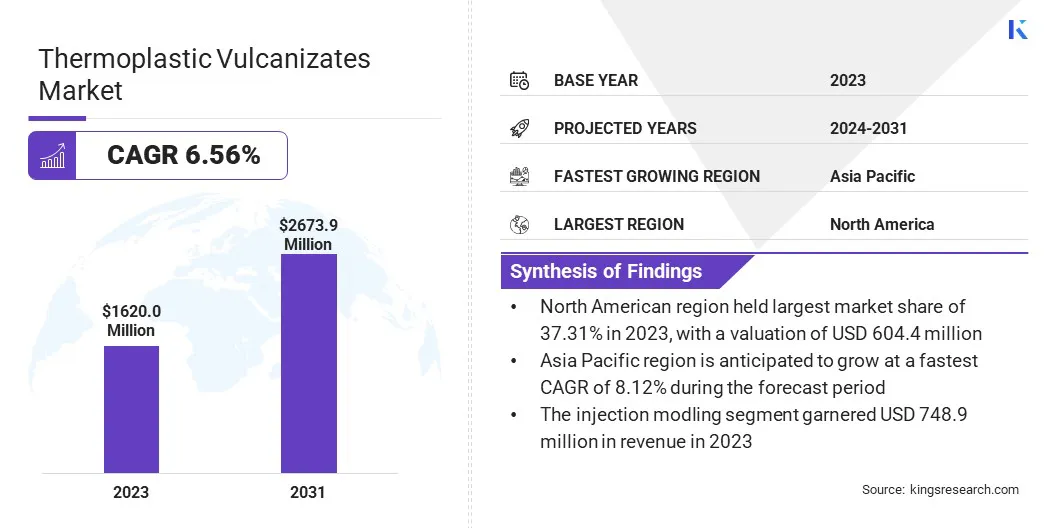

The global thermoplastic vulcanizates (TPV) market size was valued at USD 1620.0 million in 2023 and is projected to grow from USD 1713.7 million in 2024 to USD 2673.9 million by 2031, exhibiting a CAGR of 6.56% during the forecast period.

The global increase in thermoplastic vulcanizate demand is primarily driven by growing need for light weighing component within the automotive sector, rising focus on sustainability, and advancements in material technology and processing.

In the scope of work, the report includes products offered by companies such as Celanese Corporation, Mitsubishi Chemical Group Corporation, Tenkor Apex Company, RTP Company, Lotte Chemical Corporation, BASF, Mitsui Chemicals, Inc., Apar Industries Ltd., Arkema Group, and LyondellBasell Industries, among others.

Ongoing research and development within the thermoplastic vulcanizates market has broadened product applicability beyond traditional automotive and construction applications. TPVs are now gaining traction in the medical and healthcare sector as they exhibit a high degree of compliance with stringent requirements for material biocompatibility, sterilization resistance, and patient safety.

The expanding medical industry presents significant opportunities for the use of TPVs in medical devices, including fluid management tubing and soft-touch components.

- In 2023, Celanese, a global chemical leader supplied Santoprene TPV for the development of tubing for peristaltic medical pumps. Santoprene TPVs in these devices maintain consistent fluid level and extend the pump life.

Thermoplastic vulcanizates are a unique category of materials that exhibit the properties of both thermoplastics and vulcanized rubber. This unique blend enables repeated melting and reshaping without significant property degradation, while simultaneously delivering excellent elasticity and flexibility.

This inherent versatility makes TPVs highly adaptable to various processing techniques, including injection molding, extrusion molding, and blow molding, driving their widespread adoption in key manufacturing processes across diverse sectors such as automotive, construction, architecture, and consumer goods.

Analyst’s Review

Recent technological advancements have intensified competition within the thermoplastic vulcanizates market. In response to this evolving competitive landscape, companies will have to make substantial investments in research and development (R&D) to develop next-generation TPV formulations with enhanced performance characteristics.

These R&D efforts, focused on improving key properties such as heat resistance, chemical resistance, and weatherability, with a strong emphasis on sustainable material solutions, will likely position companies at the forefront of the market growth.

To capitalize on the increasing market demand, companies are expanding their production capacity by establishing new manufacturing sites in strategic regions such as India, China, and South Korea. This expansion is further supported by collaborations and partnerships with domestic players across the value chain, encompassing raw material suppliers, processors, and end-users, with the objective of maximizing market penetration and development of new market applications.

- In April 2024, Celanese, a global specialty material and chemical leader expanded its manufacturing operations in China for Santoprene thermoplastic vulcanizate (TPV). This expansion is designed to strengthen the company's supply network within the Asian market and capitalize on the increasing regional demand for high-performance materials.

Thermoplastic Vulcanizates Market Growth Factors

Thermoplastic vulcanizates is a crucial material solution for the global automotive industry, addressing the growing need for lightweight, high-performance components. A primary driver of TPV adoption is the ongoing pursuit of higher fuel economy by utilizing light weight components. TPVs works as an efficient alternative to traditional rubber, enabling weight reduction without sacrificing performance.

Moreover, the demanding operations of modern vehicles require exceptionally durable materials. TPVs deliver this by offering excellent resistance to temperature fluctuations, chemical exposure, and weathering, in a wide range of automotive applications.

Furthermore, increasing emphasis on sustainability and environmental consciousness within the manufacturing sector is significantly driving the demand for thermoplastic vulcanizates. They have become an attractive material choice for manufacturers seeking to minimize their environmental footprint and achieve sustainability targets. Heightened environmental awareness and stringent regulations are further accelerating the adoption of sustainable materials like TPVs

- In August 2023, Teknor Apex, a leading provider of custom plastic compounds, announced the launch of a new Sarlink TPV formulation with up to 40% recycled content. This addition to the Sarlink RX3100B Series of multipurpose TPVs offers enhanced sustainability while maintaining superior elasticity and long-term performance.

While TPVs exhibit promising growth, it can face competition from alternative materials, including thermoplastic polyurethanes (TPUs) and styrenic block copolymers (SBCs). To mitigate this, TPV manufacturers are developing specialized TPV grades with tailored properties to meet the specific requirements of different applications, including hardness, chemical resistance, temperature resistance, and other properties to outperform alternative materials in niche markets

Thermoplastic Vulcanizates Market Trends

There is a growing emphasis on using recycled thermoplastic vulcanizates content in new products to reduce waste and promote circular economy principles. The manufacturers of thermoplastic vulcanizates markets are focusing on developing TPVs from bio-based or renewable resources, further enhancing their sustainability profile and addressing the increasing consumer demand for eco-friendly materials.

- For instance, in October 2024, Celanese Corporation introduced three new sustainable engineering thermoplastics: Hostaform, Zytel and Vectra in Fakuma International Trade Fair for Plastics Processing. While maintaining performance characteristics comparable to traditional TPVs, these new materials support the transition toward a circular economy, enhancing Celanese's position in the growing market for sustainable solutions.

Significant investment in research and development (R&D) is further enhancing the performance of TPVs and broadening their applicability across diverse sectors. These R&D efforts have yielded new TPV formulations with improved heat resistance and chemical resistance, expanding their potential applications.

Segmentation Analysis

The global market has been segmented based on processing method, application, and geography.

By Processing Method

Based on processing method, the market has been categorized into injection molding, extrusion molding, and blow molding. The injection molding segment dominated the thermoplastic vulcanizates market accounting for USD 748.9 million in 2023.

Injection molding is a highly efficient manufacturing process that allows mass production of complex and intricate parts with high precision and accuracy. In this process, TPVs, supplied in pellet form, are melted within the injection molding machine to create a homogenous melt. This melt is then injected into a mold cavity and subsequently cooled.

TPVs exhibit excellent flow characteristics in their molten state, which effectively fill complex mold geometries and accurately reproduce fine details, ensuring high-quality part production.

By Application

Based on the application, the market is widely categorized into automotive, construction & architecture, consumer goods, electrics & electronics, and others. In 2023, the automotive industry held the highest market share of 34.98%, highlighting the its significant dependence on TPVs for various components and functionalities.

The demand for TPV components within the automotive industry is primarily driven by stringent performance specifications and the need for lightweight alternatives to traditional rubber. Automotive components are subjected to harsh conditions, including extreme temperatures, chemical exposure, and mechanical stress. TPVs are specifically engineered to withstand these demanding environments.

Their versatile properties enable diverse applications in both interior and exterior vehicle components, including door and window seals, dashboards, airbag covers, and various other parts. Beyond functional performance, TPVs also offer enhanced vehicle comfort and aesthetics.

Thermoplastic Vulcanizates Market Regional Analysis

Based on region, the global market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America.

North American thermoplastic vulcanizates market share accounted for 37.31%, which was valued at USD 604.4 million in 2023. The demand for TVPs in North America is primarily driven by its robust automotive manufacturing coupled with growing demand for high-performance materials. The presence of major automakers and suppliers actively seeking TPVs for automotive component manufacturing significantly contributes to market growth.

Consumers exhibit a strong preference for high-quality, durable, and reliable products, including electronics and consumer goods. TPVs effectively address these market demands by offering resistance to extreme temperatures, weathering, and chemical exposure to automotive fluids and other substances.

- In November 2024, Geon Performance Solutions, a global manufacturer of performance polymer solutions expanded facilities in the U.S. and Mexico. This new manufacturing line will produce thermoplastic elastomers and thermoplastic vulcanizates thereby expanding the market in North America.

Asia-Pacific region is projected to grow at a significant CAGR of 8.12% in the coming years. This market expansion can be attributed to several key factors, including rapid industrialization and manufacturing growth in the automotive, consumer goods, and electronics industries.

Furthermore, substantial infrastructure development and construction activity across the region, particularly in countries like India, China, and South Korea, are contributing to increased TPV demand for roofing membranes, window seals, and expansion joints.

Competitive Landscape

The global thermoplastic vulcanizates market report provides valuable insights with a major emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies, such as partnerships, mergers and acquisitions, product innovations, and joint ventures, to expand their product portfolio and increase their market shares across different regions.

Companies are implementing numerous strategic initiatives, such as expansion of services, investments in research and development (R&D), establishment of new service delivery centers, and optimization of service delivery processes, which are likely to create new opportunities for market growth.

List of Key Companies in Thermoplastic Vulcanizates Market

- Celanese Corporation

- Mitsubishi Chemical Group Corporation

- Tenkor Apex Company

- RTP Company

- Lotte Chemical Corporation

- BASF

- Mitsui Chemicals, Inc.

- Apar Industries Ltd.

- Arkema Group.

- LyondellBasell Industries

Key Industry Developments

- November 2024 (Launch): ContiTech, a leading company specializing in environment friendly industrial solutions, utilized thermoplastic vulcanizates to manufacture battery cooling lines for battery electric vehicles. ContiTech collaborated with Zumbach Electronics and others to achieve efficiency in TPV hose manufacturing.

- July 2024 (Launch): LyondellBasell, a market leader in chemical industry, launched Schulamid ET100 polymide based product line. These products are designed for automotive interiors, including door window frames and others.

- October 2023 (Product Launch): Celanese Corporation, a global leader in specialty materials and chemicals, launched new engineering thermoplastic solutions for commercial manufacturers of TPV, PBT, and PP applications. These new offerings, derived from recycled content, reinforce the company's commitment to transitioning toward a more circular economy and providing sustainable material options for its customers.

The global thermoplastic vulcanizates market has been segmented:

By Processing Method Type

- Injection Molding

- Extrusion Molding

- Blow Molding

By Application

- Automotive

- Construction & Architecture

- Consumer goods

- Electric & Electronics

- Others

By Region

- North America

- Europe

- France

- UK

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America