Market Definition

Textile chemicals are specialized formulations used during fiber production and fabric processing to enhance material performance and durability. They include pre-treatment, dyeing, printing, finishing, and coating agents that improve color fastness, texture, and resistance to wear.

The scope of the market covers applications in apparel, home furnishings, industrial textiles, and technical fabrics, where quality and functionality are essential. Industries such as clothing, interior décor, automotive, and protective gear rely on these chemicals to ensure consistency and meet performance standards.

Textile Chemicals Market Overview

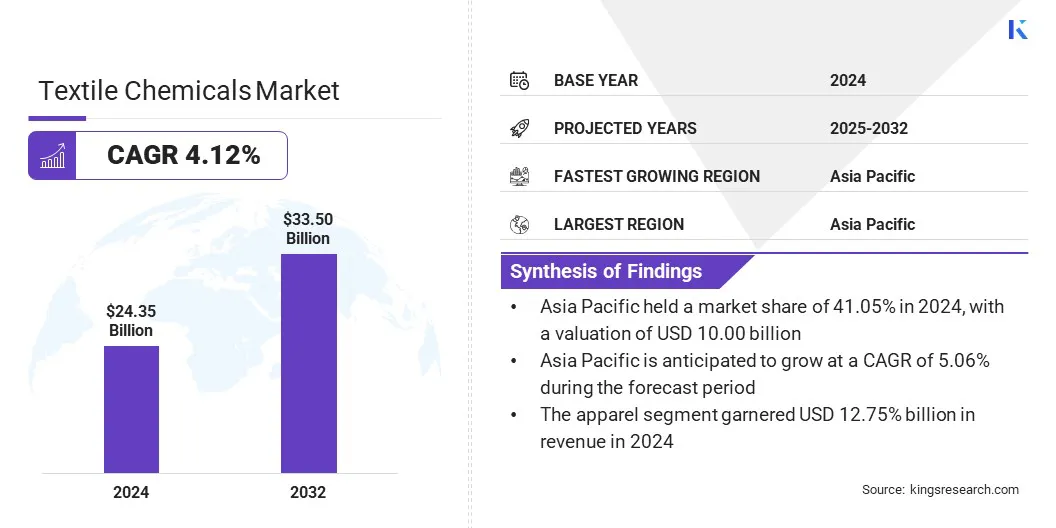

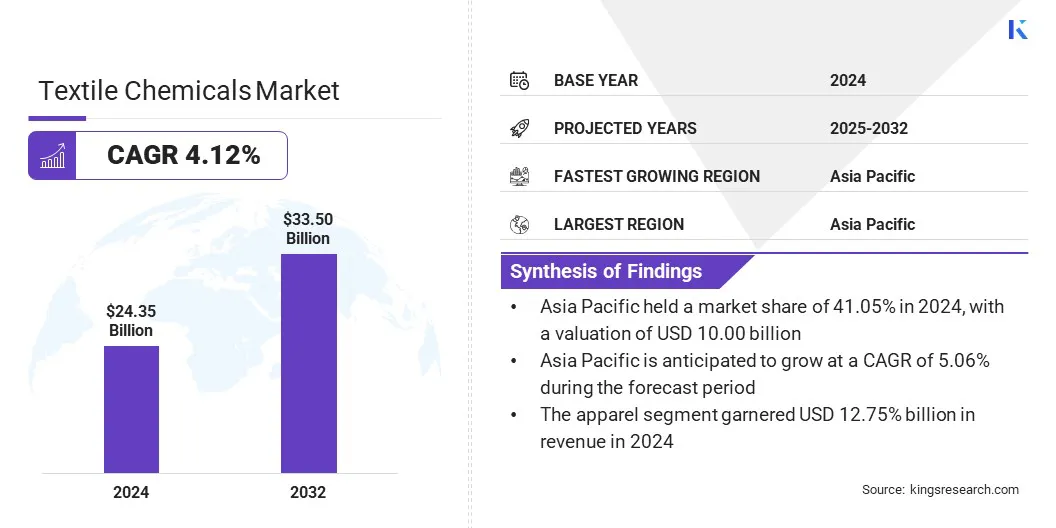

The global textile chemicals market size was valued at USD 24.35 billion in 2024 and is projected to grow from USD 25.26 billion in 2025 to USD 33.50 billion by 2032, exhibiting a CAGR of 4.12% during the forecast period.

This growth is driven by the growing demand for sustainability and eco-friendly formulations, with manufacturers focusing on low-impact auxiliaries and biodegradable finishing agents to align with regulatory and consumer requirements. Additionally, adoption of digital and waterless printing technologies is boosting the use of specialized dyes, pre-treatment agents, and printing auxiliaries that enhance resource-efficient processes.

Key Highlights

- The textile chemicals industry size was valued at USD 24.35 billion in 2024.

- The market is projected to grow at a CAGR of 4.12% from 2025 to 2032.

- Asia Pacific held a share of 41.05% in 2024, valued at USD 10.00 billion.

- The colorants & auxiliaries segment garnered USD 7.74 billion in revenue in 2024.

- The apparel segment is expected to reach USD 17.72 billion by 2032.

- Middle East & Africa is anticipated to grow at a CAGR of 4.27% over the forecast period.

Major companies operating in the textile chemicals market are Archroma, BASF SE, Huntsman International LLC, DyStar Group, Clariant, Covestro AG, EVONIK, Solvay, Lubrizol, LANXESS, Dow, Kemira, Kiri Industries Ltd., Tanatex Chemicals B.V., and RUDOLF Holding SE & Co. KG.

Rising global demand for apparel and home furnishings is fueling market growth. Increasing production of garments, upholstery, and décor items is creating steady demand for finishing, dyeing, and printing formulations. In September 2024, Textile Exchange reported that global fiber production reached an all-time high of 124 million tonnes in 2023, up from 116 million tonnes in 2022.

Textile producers are adopting advanced chemical treatments to enhance colorfastness, texture, and durability in fabrics. This shift is prompting suppliers to develop products that meet performance needs and maintain fabric quality during mass production.

Expanding textile hubs in developing economies are presenting significant opportunities for chemical suppliers in apparel and home textiles. Growing demand for sustainable and eco-friendly solutions is further reinforcing the importance of textile chemicals in modern production.

Growing emphasis on low-VOC, bio-based, and water-saving chemicals is propelling the expansion of the textile chemicals market. In May 2024, Textile Exchange published its "Sustainability of Biosynthetics Report," outlining the textile industry's mission to reduce greenhouse gas (GHG) emissions from fiber and raw material production by 45% by 2030.

Fiber manufacturing companies are increasingly adopting eco-friendly formulations to comply with stringent environmental regulations. Rising consumer preference for sustainably produced textiles is prompting brands to source chemically treated fabrics responsibly.

In response, chemical suppliers are developing innovations that reduce water usage and hazardous emissions. Rising global awareness of environmental impact is further accelerating the adoption of greener chemicals in apparel and home textile production.

- In October 2024, Archroma introduced its Planet Conscious Solutions range, emphasizing sustainable textile treatments that enhance functionality and reduce environmental impact. DOROSPERS KHF, a range of high-lightfast disperse dyes, is designed to help technical textile manufacturers achieve cutting-edge performance with optimized productivity and enhanced sustainability. This solution provides optimum build-up on polyester microfiber, including artificial suede for car interiors.

Environmental and Wastewater Concerns

A key challenge impeding the expansion of the textile chemicals market is managing effluent generated from dyeing and finishing processes. These wastewater streams contain hazardous chemicals, complicating treatment and increasing strict regulatory compliance pressures. Improper handling can lead to environmental pollution, fines, and reputational damage for manufacturers.

To address this challenge, market players are investing in advanced wastewater treatment systems, adopting eco-friendly chemicals, and implementing closed-loop processes. These actions are reducing environmental impact and helping companies meet regulatory standards effectively.

- In June 2025, the South Gujarat Textile Processors Association (SGTPA) initiated a collaborative project to construct a 600 million liters per day (MLD) deep-sea discharge pipeline. This infrastructure aims to manage effluent from seven textile processing plants in Surat, India, by releasing treated wastewater into the sea.

Rising Adoption of Digital and Waterless Printing Technologies

A key trend influencing the textile chemicals market is the rising adoption of digital and waterless printing methods to improve environmental performance. These technologies are reducing water consumption significantly while limiting the release of hazardous chemicals during dyeing processes.

Digital printing is allowing precise application of color, minimizing overuse of dyes, and enhancing fabric quality. Waterless systems are supporting lower energy use and reducing effluent treatment requirements for textile manufacturers. Apparel, home textiles, and technical fabrics are benefiting from faster production cycles and consistent coloration.

- In June 2024, Lenzing, Exponent Envirotech, and Cobalt Fashion partnered to introduce the ECOHUES waterless dyeing technology. This innovation employs a non-aqueous solvent that is 99.8% recyclable, eliminating water usage and reducing chemical consumption. Additionally, it streamlines pretreatment and finishing processes, minimizing the need for post-dyeing soap washing.

Textile Chemicals Market Report Snapshot

|

Segmentation

|

Details

|

|

By Product Type

|

Coating & Sizing Agents, Colorants & Auxiliaries, Finishing Agents, Surfactants, Desizing Agents, Others

|

|

By Application

|

Apparel, Home Textiles, Technical Textiles

|

|

By Region

|

North America: U.S., Canada, Mexico

|

|

Europe: France, UK, Spain, Germany, Italy, Russia, Rest of Europe

|

|

Asia-Pacific: China, Japan, India, Australia, ASEAN, South Korea, Rest of Asia-Pacific

|

|

Middle East & Africa: Turkey, U.A.E., Saudi Arabia, South Africa, Rest of Middle East & Africa

|

|

South America: Brazil, Argentina, Rest of South America

|

Market Segmentation

- By Product Type (Coating & Sizing Agents, Colorants & Auxiliaries, Finishing Agents, Surfactants, Desizing Agents, and Others): The colorants & auxiliaries segment earned USD 7.74 billion in 2024, mainly due to the rising demand for high-performance dyes, pigments, and processing aids that enhance color fastness, printing precision, and fabric quality.

- By Application (Apparel, Home Textiles, and Technical Textiles): The apparel segment held a share of 52.35% in 2024, mainly attributed to strong demand for dyes, finishing agents, and specialty auxiliaries to support diverse clothing styles and performance fabrics.

Textile Chemicals Market Regional Analysis

Based on region, the market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and South America.

Asia Pacific textile chemicals market share stood at 41.05% in 2024, valued at USD 10.00 billion. This dominance is reinforced by the region’s strong textile manufacturing base.

China's National Bureau of Statistics reported a 14.26% year-over-year increase in textile and apparel exports in the first two months of 2024. This growth was supported by strong international demand and government measures. Specifically, apparel exports rose by 13.1%, while textile exports grew by 15.5%.

The presence of numerous spinning, weaving, and garment manufacturing units creates high demand for textile chemicals such as dyes, finishing agents, and sizing chemicals. This concentration of manufacturing hubs makes the region a major market for both basic and specialized textile chemicals, attracting international suppliers seeking reliable, high-volume buyers.

The textile chemicals industry in Middle East & Africa is expected to grow at a CAGR of 4.27% over the forecast period. This growth is propelled by the expansion of construction and infrastructure projects, which boost demand in commercial, residential, and hospitality sectors for interior textiles and upholstery.

Textile chemicals are essential for treating fabrics for curtains, carpets, and upholstery, improving durability and appearance. Moreover, the expansion of textile manufacturing facilities is boosting regional market growth, as these facilities require a steady supply of textile chemicals for dyeing, finishing, and coating. Rising local production reduces dependency on imports and creates a stable demand for chemical suppliers.

- According to the International Trade Center, Africa accounts for 10% of global cotton exports and holds the potential to export cotton garments worth USD 6.87 billion to international and intra-African markets by 2026.

Regulatory Frameworks

- In the U.S., textile chemicals are regulated under the Consumer Product Safety Commission (CPSC), which enforces flammability standards such as 16 CFR 1610 for general clothing and 16 CFR 1615 & 1616 for children's sleepwear. The Environmental Protection Agency (EPA) governs hazardous substances under the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA).

- In the European Union textile chemicals fall under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH), requiring manufacturers to submit substance data to the European Chemicals Agency (ECHA). The Textile Regulation (EU) No 1007/2011 defines fiber-content labeling requirements for textile goods.

- In China, textile chemicals are governed under the Standardization Administration of China (SAC), which issues mandatory national standards (GB) for textile products, including those related to chemical content. The Environmental Protection Law sets requirements for the discharge of pollutants, including those from textile manufacturing processes.

- In Japan, textile chemicals are covered under the Household Goods Quality Labeling Act, which requires accurate labeling of textile products, including information on chemical content. The Chemical Substances Control Law supervises the manufacture and import of chemical substances, including those used in textiles. The Pollution Control Law establishes standards for the discharge of pollutants from textile manufacturing processes.

Competitive Landscape

Major players operating in the textile chemicals industry are investing in research and development to create eco-friendly surfactants and auxiliaries, forming partnerships with brands to deliver sustainable textile-care solutions, and advancing production technologies to lower resource consumption during fabric processing.

They are also focusing on developing high-performance cleaning agents that meet stricter environmental standards while maintaining efficiency in textile applications. Several companies are modernizing formulation processes to improve biodegradability and reduce energy or water use.

These efforts help them strengthen their portfolios, comply with evolving regulations, and remain competitive as demand grows for sustainable solutions in textile processing and maintenance.

- In October 2024, Clariant introduced sustainable cleaning and detergent solutions, including the GlucoPure Sense, a multifunctional sugar surfactant, and the TexCare Terra range for textile-care applications These products are designed to support reduced resource consumption in textile processing.

Key Companies in Textile Chemicals Market:

- Archroma

- BASF SE

- Huntsman International LLC

- DyStar Group

- Clariant

- Covestro AG

- EVONIK

- Solvay

- Lubrizol

- LANXESS

- Dow

- Kemira

- Kiri Industries Ltd.

- Tanatex Chemicals B.V.

- RUDOLF Holding SE & Co. KG

Recent Developments (Agreement/Product Launches)

- In March 2025, TANATEX Chemicals signed a global distribution agreement with Fresche Bioscience for its anti-microbial textile solutions. The deal covers Fresche’s Quatlock-based treatments, which have been tested in more than 500 independent laboratory tests and are intended to protect textiles from bacteria, fungi, and other microorganisms.

- In September 2024, Evonik launched biosurfactants, including TEGO Wet 570 Terra and TEGO Wet 580 Terra, for coatings and inks, with applications across textile, inks, and finishing formulations.

- In January 2024, BASF and Inditex launched loopamid, a polyamide 6 made entirely from textile waste, leveraging BASF’s chemical depolymerization and re-polymerization to convert discarded nylon garments into virgin-grade fibres.