Microreactor Technology Market Size

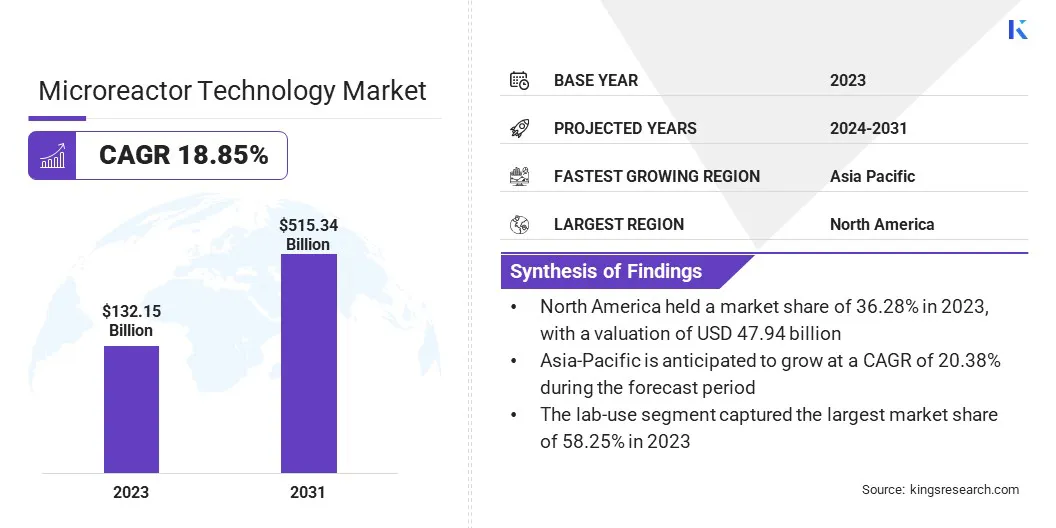

Global Microreactor Technology Market size was recorded at USD 132.15 billion in 2023, which is estimated to be at USD 153.83 billion in 2024 and projected to reach USD 515.34 billion by 2031, growing at a CAGR of 18.85% from 2024 to 2031. Advancements in microfabrication techniques have played a pivotal role in catalyzing the growth and application of microreactor technology. In the scope of work, the report includes services offered by companies such as Corning Incorporated, Chemtrix, Syrris Ltd, Uniqsis Ltd, Little Things Factory GmbH, Ehrfeld Mikrotechnik GmbH, FutureChemistry, AM Technology, Vapourtec Ltd., Bronkhorst, and others.

Microfabrication, the process of fabricating miniature structures, has evolved remarkably due to innovations in materials science, nanotechnology, and precision engineering. These advancements allow for the creation of microreactors with intricate designs and enhanced functionalities that were previously unattainable. Techniques such as photolithography, micro-milling, and 3D printing have become more refined, enabling the production of microreactors with higher precision, better scalability, and improved durability. The use of advanced materials such as silicon, glass, and specialized polymers has further enhanced the chemical resistance and thermal stability of microreactors.

These improvements have enabled the production of microreactors capable of handling a wide range of chemical reactions with high efficiency and safety. The miniaturization of reactors facilitates better control over reaction conditions, leading to higher yields and purity of products. In response to this, diverse industries such as pharmaceuticals, fine chemicals, and biotechnology are increasingly adopting microreactors for their production processes, leveraging these technological advancements to achieve more efficient, cost-effective, and sustainable chemical manufacturing.

Microreactor technology refers to the use of miniaturized, modular chemical reactors that facilitate chemical reactions on a small scale with enhanced control and efficiency. These microreactors are typically composed of channels with diameters in the micrometer range, which allow for precise control over reaction parameters such as temperature, pressure, and residence time. There are various types of microreactors, including continuous flow microreactors, batch microreactors, and catalytic microreactors. Continuous flow microreactors enable the continuous processing of chemicals, leading to consistent product quality and improved safety due to the smaller volumes of reactants involved.

Batch microreactors, on the other hand, are suitable for processes that require discrete quantities of reactants to be processed sequentially. Catalytic microreactors incorporate catalysts within the microchannel structures to accelerate specific chemical reactions. The applications of microreactor technology are diverse and span multiple industries.

In pharmaceuticals, they are used for drug synthesis and formulation, offering rapid screening of reaction conditions and efficient scale-up from laboratory to production. In the fine chemicals industry, microreactors are employed for the synthesis of high-value compounds with precise control over reaction conditions. Additionally, in the field of biotechnology, microreactors facilitate enzymatic reactions and cell culture processes, thereby contributing to advancements in bioprocessing and personalized medicine.

Analyst’s Review

Key market players are focusing on several strategic imperatives to maintain and enhance their competitive edge. One of the primary strategies involves extensive investment in research and development to innovate and refine microreactor designs, making them more versatile and efficient. Companies are further forming strategic partnerships and collaborations with academic institutions and other industry players to foster innovation and expand their technological capabilities.

Moreover, there is a growing emphasis on the integration of digital technologies, such as IoT and AI, to enhance the monitoring, control, and optimization of microreactor systems. This digital integration facilitates predictive maintenance and real-time data analysis, thereby ensuring higher operational efficiency and reduced downtime.

Furthermore, market players are placing emphasis on geographical expansion strategies, aiming to tap into emerging markets with high growth potential by establishing local manufacturing units and service centers. Additionally, there is a growing focus on developing sustainable and environmentally friendly solutions, aligning with global green initiatives and regulatory requirements.

Microreactor Technology Market Growth Factors

Increased investment in pharmaceutical research and development (R&D) is significantly fostering the use of microreactors in both drug discovery and production processes. The pharmaceutical industry faces ongoing demands for innovation and expedite, cost-efficient introduction of new drugs to market. Microreactors, due to their precise control over reaction conditions, are becoming invaluable tools in this process. These miniaturized reactors allow for rapid screening of chemical reactions, enabling researchers to identify optimal conditions for drug synthesis with unprecedented speed and accuracy.

Additionally, microreactors facilitate continuous flow chemistry, which streamlines the production process and reduces costs associated with batch production methods. The enhanced safety and scalability of microreactors make them particularly attractive for producing active pharmaceutical ingredients (APIs), as they minimize the risk of hazardous reactions and allow for easy scale-up from laboratory to commercial production.

As pharmaceutical companies allocate more resources towards R&D, the adoption of microreactor technology is expected to grow, driven by the rising need for more efficient, sustainable, and flexible manufacturing processes. The high initial capital investment required for microreactor technology implementation poses a significant barrier for many organizations, particularly small and medium-sized enterprises (SMEs). The development and deployment of microreactor systems involve substantial costs related to advanced materials, precision engineering, and sophisticated control systems.

Additionally, setting up the necessary infrastructure for microreactor operations, including specialized equipment and facilities, escalates the financial burden. For SMEs, these costs are prohibitive, limiting their ability to adopt this advanced technology despite its potential benefits. Large-scale enterprises possess the financial capacity to invest in microreactor technology. However, they face challenges related to substantiating the return on investment (ROI) within a reasonable timeframe. The perceived risk associated with the high upfront costs deter well-funded organizations from transitioning to microreactor-based processes.

Moreover, the need for specialized training and expertise to operate and maintain microreactor systems adds another layer of complexity and expense. Overcoming these financial barriers requires innovative funding solutions, such as government grants, subsidies, and industry partnerships, to make microreactor technology more accessible and economically viable for a broader range of companies.

Microreactor Technology Market Trends

The microreactor technology market is experiencing robust growth, driven by rising demand for efficient chemical synthesis, pharmaceuticals, and sustainable energy solutions. Key trends include advancements in modular and scalable designs, integration with automation and AI for enhanced process control, and increasing adoption in bioprocessing and fine chemicals manufacturing.

Additionally, regulatory support and investment in green technologies are fueling market expansion. Companies are focusing on innovation and strategic partnerships to capitalize on emerging opportunities. The push for miniaturization and precision in chemical processes is set to further propel the microreactor technology market.

Segmentation Analysis

The global microreactor technology market is segmented based on type, application, and geography.

By Type

Based on type, the market is segmented into lab-use and production-use. The lab-use segment captured the largest market share of 58.25% in 2023. Laboratories across various industries, including pharmaceuticals, biotechnology, and chemical synthesis, rely heavily on microreactor technology for research, experimentation, and process development. The versatility and precision offered by microreactors make them indispensable tools for conducting a wide range of chemical reactions in controlled environments.

Moreover, the increasing emphasis on efficiency and sustainability in laboratory operations has led to the adoption of microreactors. These devices offer benefits such as reduced reaction times, lower solvent consumption, and enhanced product yields compared to traditional batch reactors. Additionally, advancements in microreactor design and manufacturing have made these systems more accessible and user-friendly for laboratory settings, thereby fueling their widespread adoption.

By Application

Based on application, the market is classified into specialty chemicals, pharmaceuticals, commodity chemicals, and others. The specialty chemicals segment is poised to observe substantial growth, recording a staggering CAGR of 20.47% over the forecast period. Specialty chemicals are characterized by their unique properties and high value-addition, catering to niche markets with specific performance requirements. Microreactor technology offers significant advantages for the synthesis of specialty chemicals, allowing for precise control over reaction conditions and the production of complex molecular structures with exceptional purity and consistency.

As the demand for specialty chemicals continues to rise across diverse applications such as pharmaceuticals, agrochemicals, and electronics, manufacturers are increasingly turning to microreactors to streamline production processes and enhance product quality. Moreover, the growing emphasis on sustainability and green chemistry practices is leading to the widespread adoption of microreactors, which enable more efficient and environmentally friendly synthesis routes for specialty chemicals.

Microreactor Technology Market Regional Analysis

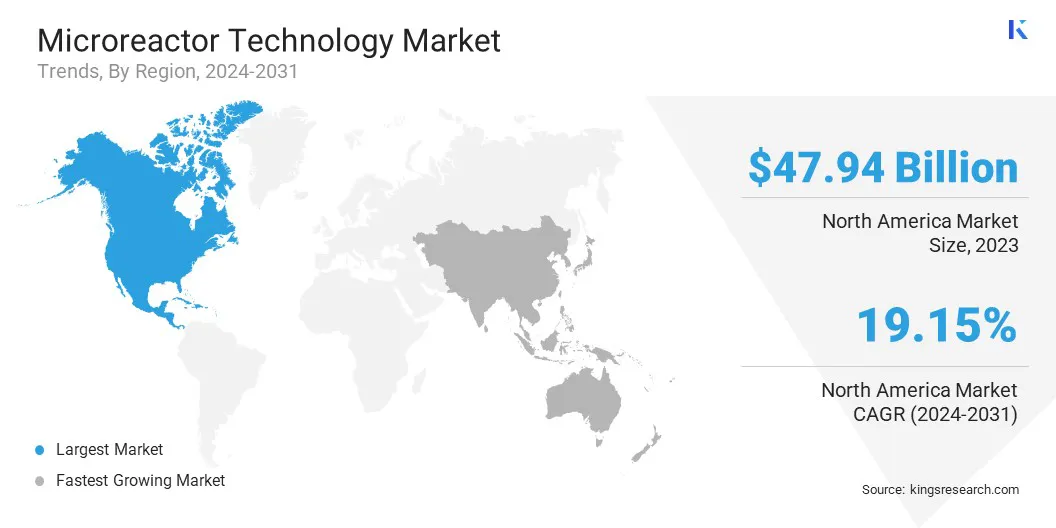

Based on region, the global microreactor technology market is classified into North America, Europe, Asia Pacific, MEA, and Latin America.

The North America Microreactor Technology Market share stood around 36.28% in 2023 in the global market, with a valuation of USD 47.94 billion. The region is home to a robust pharmaceutical and biotechnology industry, where microreactors are extensively utilized for drug discovery, development, and production. The region's strong research infrastructure and increased investment in innovation contribute to the widespread adoption of microreactors in laboratory and industrial settings.

Additionally, stringent regulatory standards and a growing focus on sustainability boost the demand for advanced manufacturing technologies such as microreactors, which offer improved efficiency and environmental performance compared to traditional batch reactors. Moreover, the presence of key market players and the establishment of strategic partnerships between academic institutions, government agencies, and industry stakeholders bolster the growth of the North America microreactor technology market.

Asia-Pacific is poised to experience staggering growth at a CAGR of 20.38% in the foreseeable future. The region is witnessing rapid industrialization and economic growth, leading to increased demand for specialty chemicals, pharmaceuticals, and other high-value products that utilize microreactor technology. Moreover, the region's burgeoning population and rising healthcare expenditures result in an increased demand for innovative drug discovery and production solutions, where microreactors offer significant advantages in terms of efficiency, scalability, and cost-effectiveness.

Additionally, supportive government policies, investment incentives, and initiatives to promote innovation and technological advancement propel the adoption of microreactor technology in Asia-Pacific.

- For instance, in February 2024, Shimadzu Corporation acquired the catalytic microreactor business for gas chromatography from Activated Research Company, LLC, bolstering its competitive edge in the Green Transformation (GX) sector of gas chromatography.

Furthermore, the region's expanding research capabilities, skilled workforce, and strong manufacturing base solidify its position as a key market for microreactor technology. With favorable market conditions and growing awareness of the benefits of microreactors, Asia-Pacific is poised to become a major hub for microreactor technology innovation and adoption in the upcoming years.

Competitive Landscape

The global microreactor technology market study will provide valuable insight with an emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions. Manufacturers are adopting a range of strategic initiatives, including investments in R&D activities, the establishment of new manufacturing facilities, and supply chain optimization, to strengthen their market standing.

List of Key Companies in Microreactor Technology Market

- Corning Incorporated

- Chemtrix

- Syrris Ltd

- Uniqsis Ltd

- Little Things Factory GmbH

- Ehrfeld Mikrotechnik GmbH

- FutureChemistry

- AM Technology

- Vapourtec Ltd.

- Bronkhorst

Key Industry Developments

- March 2024 (Partnership): Prodigy Clean Energy and Des Nedhe Group signed a memorandum of understanding (MoU) to investigate the potential deployment of Prodigy's microreactor Transportable Nuclear Power Plants (TNPPs) for powering remote mining operations and communities across Canada.

- October 2023 (Launch): Westinghouse Electric Company launched a new design and manufacturing facility near downtown Pittsburgh to expedite eVinci microreactor commercialization. In June 2023, they established eVinci Technologies LLC to streamline the microreactor's market introduction as a separate business unit.

The Global Microreactor Technology Market is Segmented as:

By Type

By Application

- Specialty Chemicals

- Pharmaceuticals

- Commodity Chemicals

- Others

By Region

- North America

- Europe

- France

- U.K.

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America