Market Definition

A membrane contactor is a separation device that enables controlled mass transfer between a liquid and a gas through a hydrophobic membrane. It provides an efficient alternative to conventional absorption, stripping, and degassing methods.

The technology is widely applied in water and wastewater treatment, microelectronics, power generation, pharmaceuticals, and food and beverage processing. Its ability to deliver precise gas–liquid transfer supports applications such as carbon dioxide removal, oxygenation, nitrogen stripping, and ultrapure water production.

According to Kings Research, the global membrane contactor market size was valued at USD 385.4 million in 2024 and is projected to grow from USD 406.2 million in 2025 to USD 615.7 million by 2032, exhibiting a CAGR of 6.12% during the forecast period.

This growth is attributed to the increasing adoption of advanced gas–liquid transfer systems in water and wastewater treatment, supported by stricter discharge regulations and the need for reliable, clean water supply.

Rising demand from power generation, microelectronics, and semiconductor industries is further driving utilization due to the requirement for ultrapure water and controlled degassing processes.

Key Market Highlights:

- The membrane contactor industry size was valued at USD 385.4 million in 2024.

- The market is projected to grow at a CAGR of 6.12% from 2025 to 2032.

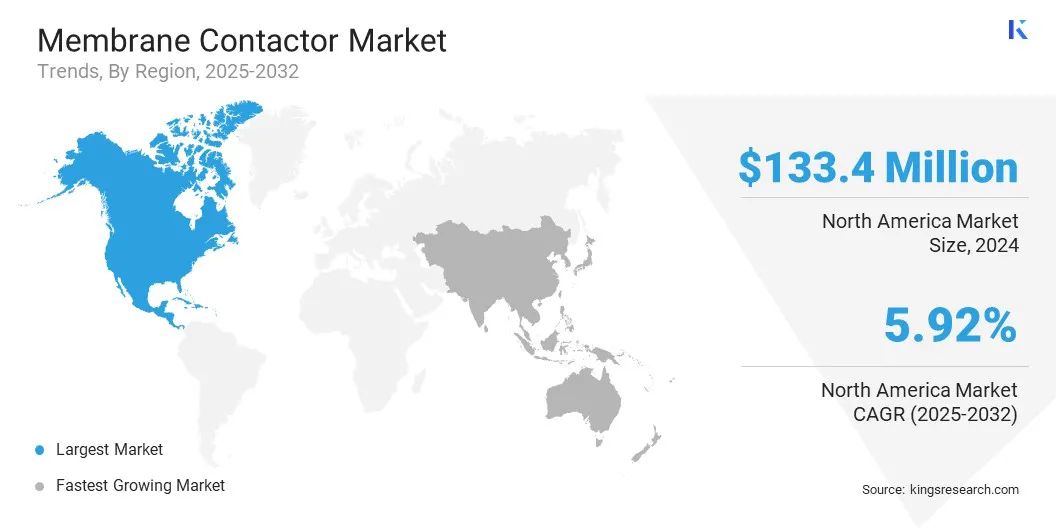

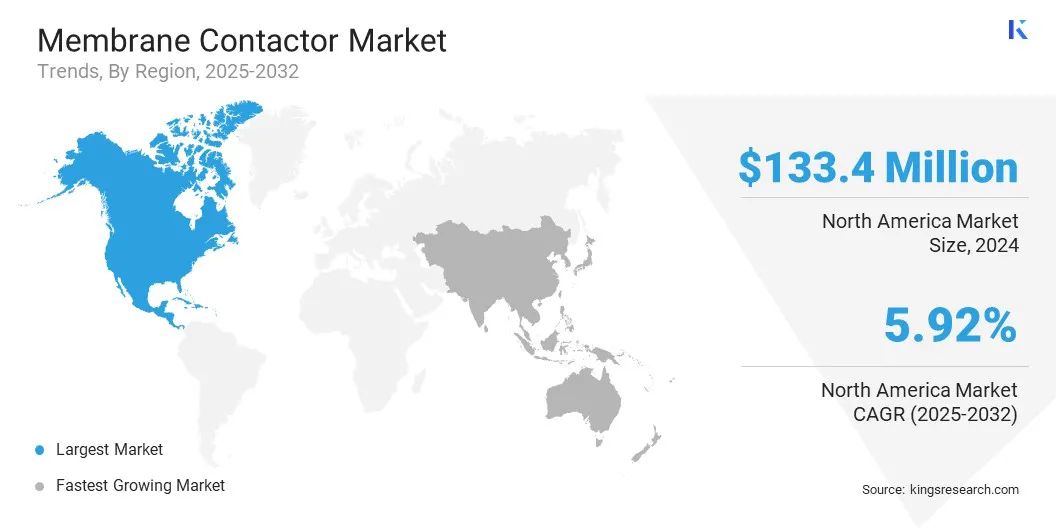

- North America held a share of 34.62% in 2024, valued at USD 133.4 million.

- The hollow fiber segment garnered USD 221.3 million in revenue in 2024.

- The polypropylene segment is expected to reach USD 252.4 million by 2032.

- The microelectronics & semiconductors segment is anticipated to witness the fastest CAGR of 6.79% during the forecast period.

- Asia Pacific is anticipated to grow at a CAGR of 6.72% through the projection period.

Major companies operating in the membrane contactor market are 3M, Cobetter, EUROWATER, Pure Water Group, Deionx, Wuhan Tanal Industrial Co., Ltd., Veolia, Jiangsu Kaimi Membrane Technology Co., Ltd., Anhui Sci-Nano Membrane Technology Co., ltd., Linde PLC, Delta Filtration Material Co., Ltd, Dongturbo Electric Company Ltd., Hebei Lan Ze Instrument Technology Co., Ltd., APPLIED MEMBRANES INC., and PTI Pacific Pty. Ltd.

The focus on operational efficiency, compact system design, and consistent performance is promoting wider deployment of membrane contactors across industrial applications. Additionally, ongoing innovations in membrane materials, improved module configurations, and expanding use in pharmaceuticals and food processing are boosting market growth.

- In December 2024, Chemical Engineering Science (Elsevier) published a study on an advanced membrane contactor with electrodialysis metathesis for CO₂ capture and waste salt remediation. The system achieved 78.94% CO₂ removal, produced ammonium bicarbonate at 88.73% yield, and recovered sodium bicarbonate at 90.9% yield and 97.8% purity, demonstrating a cost-effective and stable solution for sustainable carbon capture.

Growing Adoption of Optimized Water & Wastewater Treatment Processes

The growth of the membrane contactor market is fueled by the growing adoption of optimized water and wastewater treatment processes across municipal, industrial, and commercial applications. In September 2023, Science of The Total Environment published a study on an ozone membrane contactor for tertiary treatment of urban wastewater.

The system reduced chemical oxygen demand, total suspended solids, and microbial contaminants, indicating its potential role in wastewater treatment processes.

Furthermore, rising concerns over water scarcity, regulatory compliance, and the need for consistent water quality are fostering investment in efficient gas–liquid separation solutions.

Membrane contactors enable degassing, carbon dioxide removal, and oxygenation while maintaining energy efficiency and operational reliability, providing an effective alternative to conventional absorption and stripping methods. Their compact design and high mass transfer efficiency make them suitable for diverse water treatment applications.

Industrial demand, environmental regulations, and sustainability considerations are further contributing to broader deployment. Utilities and industries are incorporating membrane contactor systems to improve process efficiency, ensure compliance, and maintain reliable water management, supporting market expansion.

Membrane fouling and scale formation present significant challenges to the expansion of the membrane contactor market. Deposits of solids, biological matter, or minerals reduce mass transfer efficiency, increase energy consumption, and shorten membrane lifespan.

Regular cleaning, maintenance, and membrane replacement further increase operating costs and can affect system reliability.

These issues are more pronounced in industries handling complex water or wastewater streams, including power generation, pharmaceuticals, and food and beverage processing, where fouling and scaling occur faster. Limited skilled personnel to operate and maintain systems further constrain adoption.

To mitigate these challenges, manufacturers are developing fouling- and scaling-resistant membranes, implementing advanced pretreatment methods, and integrating monitoring systems. These measures aim to extend membrane life, reduce maintenance needs, and maintain system efficiency, supporting more reliable and cost-effective operation.

- In April 2023, Elsevier published a review in the Journal of Membrane Science detailing advancements in membrane contactor technology. The paper highlights the development of more durable and fouling-resistant membrane materials. It also covers optimized module and system configurations and improved integration with gas separation, carbon dioxide capture, and sulfur removal processes.

Rising Shift Toward Process-Intensified System Designs

The membrane contactor market is witnessing a shift toward process-intensified system designs, supported by the need for compact, energy-efficient, and high-performance gas–liquid transfer solutions.

Integration of membrane contactors into intensified systems improves mass transfer efficiency, reduces operational costs, and minimizes system footprint while meeting performance and sustainability requirements.

This trend is prominent in water and wastewater treatment, pharmaceuticals, power generation, and food and beverage processing, where efficiency, regulatory compliance, and resource optimization are key considerations.

Manufacturers are focusing on advanced module designs and optimized system configurations to support reliable and scalable operations. Use of automation, monitoring systems, and energy-efficient processes further enhances system performance.

The emphasis on efficiency, sustainability, and operational reliability is contributing to the broader adoption of process-intensified membrane contactor systems across industrial applications.

|

Segmentation

|

Details

|

|

By Module

|

Hollow fiber, Flat sheet, and Spiral wound

|

|

By Membrane Material

|

Polypropylene, Polytetrafluoroethylene, and Others

|

|

By Application

|

Water & Wastewater Treatment, Microelectronics & Semiconductors, Food Processing, Pharmaceutical Processing, Power & Steam Generation, Oil & Gas, and Others

|

|

By Region

|

North America: U.S., Canada, Mexico

|

|

Europe: France, UK, Spain, Germany, Italy, Russia, Rest of Europe

|

|

Asia-Pacific: China, Japan, India, Australia, ASEAN, South Korea, Rest of Asia-Pacific

|

|

Middle East & Africa: Turkey, U.A.E., Saudi Arabia, South Africa, Rest of Middle East & Africa

|

|

South America: Brazil, Argentina, Rest of South America

|

Market Segmentation

- By Module (Hollow fiber, Flat sheet, and Spiral wound): The hollow fiber segment earned USD 221.3 million in 2024, mainly due to its high surface area, efficient mass transfer, and suitability for compact system designs.

- By Membrane Material (Polypropylene, Polytetrafluoroethylene, and Others): The polypropylene segment held a share of 41.88% in 2024, propelled by its chemical resistance, durability, and cost-effectiveness in diverse water and industrial applications.

- By Application (Water & Wastewater Treatment, Microelectronics & Semiconductors, Food Processing, Pharmaceutical Processing, Power & Steam Generation, Oil & Gas, and Others): The water & wastewater treatment segment is projected to reach USD 222.6 million by 2032, owing to increasing demand for efficient degassing, carbon dioxide removal, and oxygenation in municipal and industrial treatment processes.

Based on region, the market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and South America.

North America membrane contactor market share stood at 34.62% in 2024, valued at USD 133.4 million. This strong position is reinforced by stringent environmental regulations, well-established industrial and municipal water treatment infrastructure, and high awareness of process efficiency and compliance among industries.

Furthermore, the regional market benefits from increasing adoption of membrane contactors in pharmaceuticals, power generation, and semiconductor manufacturing, where precise gas–liquid transfer and water quality are critical.

Ongoing investments in water treatment facilities and the adoption of advanced membrane technologies contribute to the steady deployment of membrane contactor systems. Industrial modernization and technological improvements in membrane design further propel regional market expansion.

- In June 2025, UC Riverside, UCLA, and Active Membranes introduced a new membrane technology in California to improve reverse osmosis efficiency. Featuring an electrically conductive coating, it reduces scaling and fouling, enhancing the treatment of brackish groundwater and wastewater. A pilot in Ventura County demonstrated a 20–30% increase in water production over conventional membranes.

The Asia-Pacific membrane contactor industry is projected to grow at a CAGR of 6.72% over the forecast period. This growth is fueled by increasing demand for efficient water and wastewater treatment solutions, supported by industrial water infrastructure development.

Expanding sectors such as pharmaceuticals, power generation, and food and beverage processing are adopting membrane contactors to maintain process efficiency and water quality. Collaborations with technology providers are facilitating system deployment and infrastructure development in the water and wastewater sector.

Furthermore, the emphasis on energy-efficient and durable membrane technologies, combined with industrial growth and stricter environmental regulations, is supporting long-term adoption. Ongoing industrial development and modernization projects further position Asia-Pacific as a key market for membrane contactors.

Regulatory Frameworks

- In the U.S., the Safe Drinking Water Act (SDWA) regulates drinking water quality. It authorizes the EPA to set minimum standards, supporting the adoption of water treatment technologies, including membrane contactors.

- In the European Union, EN 12255 Standards govern the design and construction of wastewater treatment plants. It establishes performance and safety requirements to ensure effective operation of systems, including membrane contactor installations.

Competitive Landscape

Companies operating in the membrane contactor industry maintain competitiveness through investments in advanced membrane technologies and process-intensified system designs.

Efforts focus on developing membranes with improved fouling and scaling resistance, higher mass transfer efficiency, and operational lifespan to meet diverse requirements in water treatment, pharmaceuticals, power generation, and food and beverage applications.

Product portfolios are being expanded to include hollow fiber, flat sheet, and spiral wound modules, using materials such as polypropylene and polytetrafluoroethylene to address varied industrial needs and regulatory standards.

Firms are also prioritizing localized production, automation, and monitoring systems to enhance reliability and operational efficiency. Additionally, they are emphasizing customer support, technical services, and digital tools for predictive maintenance to strengthen market position and ensure long-term system performance.

Key Companies in Membrane Contactor Market:

- 3M

- Cobetter

- EUROWATER

- Pure Water Group

- Deionx

- Wuhan Tanal Industrial Co., Ltd.

- Veolia

- Jiangsu Kaimi Membrane Technology Co., Ltd.

- Anhui Sci-Nano Membrane Technology Co., ltd.

- Linde PLC

- Delta Filtration Material Co., Ltd

- Dongturbo Electric Company Ltd.

- Hebei Lan Ze Instrument Technology Co., Ltd.

- APPLIED MEMBRANES INC.

- PTI Pacific Pty. Ltd.

Recent Developments (Product Launch)

- In August 2025, Ionada introduced its first production-scale Hollow Fiber Membrane Contactor (HFMC) carbon capture system. The unit integrates absorption and desorption to reduce size and weight compared to conventional systems, making it suitable for space-constrained industrial applications.