Electron Beam Machining Market Size

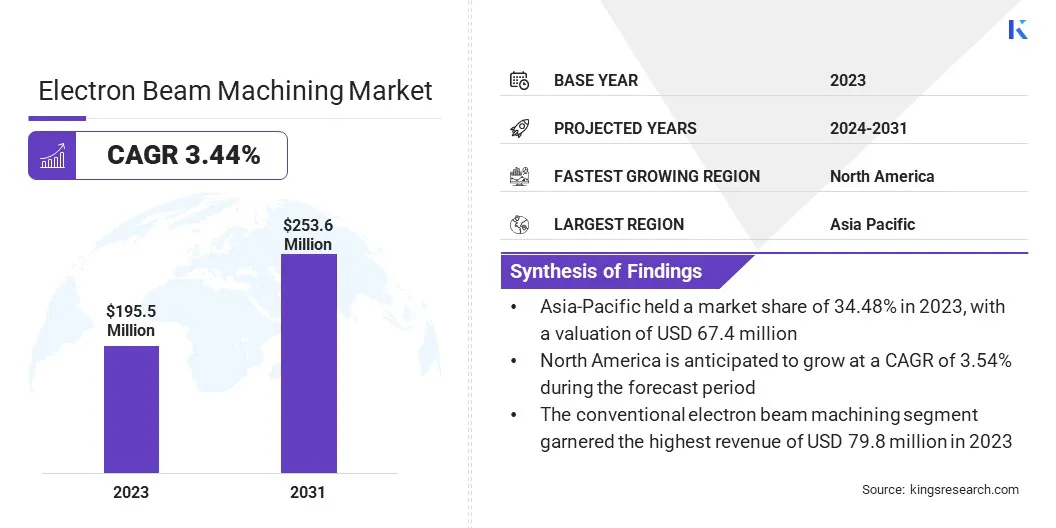

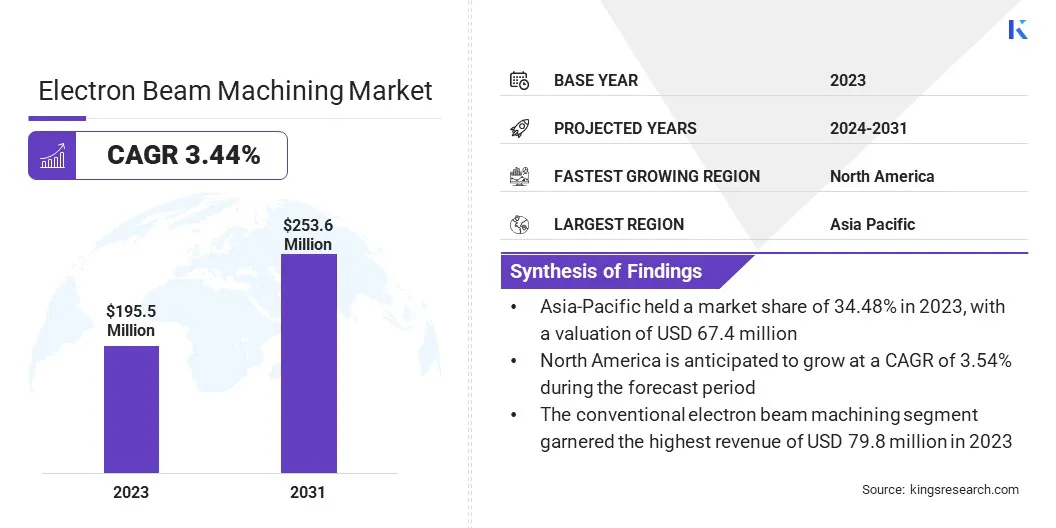

The global Electron Beam Machining Market size was valued at USD 195.5 million in 2023 and is projected to grow from USD 200.1 million in 2024 to USD 253.6 million by 2031, exhibiting a CAGR of 3.44% during the forecast period. The market is experiencing robust growth driven by the increasing demand for high-precision components in the aerospace, automotive, and healthcare industries. Advancements in electron beam technology and the rising adoption of additive manufacturing are propelling market expansion.

In the scope of work, the report includes products offered by companies such as Global Beam Technologies AG, Mitsubishi Electric Corporation, Bodycote, TETA, FOCUS GmbH, Evobeam, pro-beam GmbH, Cambridge Vacuum Engineering, Sciaky Inc., EB Industries, and others.

The growth of the electron beam machining market is primarily driven by advancements in technology and increasing demand across various industries. The aerospace segment of the market is projected to grow at a robust CAGR of 4.65% over the forecast period. This growth is attributed to the need for high-precision components and the capability of electron beam machining to produce complex, intricate parts with minimal material wastage.

Moreover, the automotive and healthcare sectors are contributing to market progress due to their requirements for high-performance and heat-sensitive materials. The rise of additive manufacturing and government support for innovative manufacturing technologies are fostering the adoption of electron beam machining. The Asia-Pacific dominated the market in 2023, mainly backed by its strong manufacturing base and increasing investments in precision engineering.

Electron beam machining (EBM) is a precision manufacturing process that utilizes a high-velocity electron beam to shape materials with exceptional accuracy. This technology operates in a vacuum environment, allowing for the machining of heat-sensitive and hard-to-machine materials without causing thermal damage or mechanical wear. The market for EBM is structured into various segments, including types of machining processes, applications, and end-use industries.

The market is moderately fragmented, with numerous key players contributing to innovation and competition. Major segments such as aerospace, automotive, and healthcare are observing rising product adoption due to their need for intricate and high-performance components. The competitive landscape is fostering continuous advancements, ensuring EBM remains a vital technology in modern manufacturing.

Analyst’s Review

Key players in the electron beam machining market are implementing several strategies to differentiate themselves and drive market growth. One such strategy is specialization in titanium 3D printing for aerospace applications. This focus on titanium and other advanced materials positions these companies as leaders in high-precision, high-performance component manufacturing, catering to the demanding requirements of space and aerospace industries.

- In November 2023, Zenith Tecnica announced its support for NASA's space exploration initiatives. Specializing in titanium 3D printing, the company was selected in partnership with satellite manufacturer Maxar Space Systems to supply materials for NASA's new spacecraft using electron beam melting technology.

Another strategic initiative includes the deployment of large-format electron beam additive manufacturing (EBAM) systems. This approach significantly enhances production capabilities and enables the fabrication of larger, more intricate components that were previously unfeasible.

- In June 2022, TAI unveiled plans to 3D print 6-meter-long aerostructures utilizing the world's largest electron beam machine from SCIAKY. The installation of the custom SCIAKY 300 Series EBAM 3D printer aims to produce titanium aerostructures for several pilot projects.

These strategies facilitate the acquisition of lucrative contracts and partnerships and foster growth by expanding technological capabilities and market presence. By prioritizing specialized, high-demand applications, these companies drive innovation and maintain a competitive edge in the market.

Electron Beam Machining Market Growth Factors

The electron beam machining market is experiencing robust growth driven by the rising demand for lightweight and high-performance components across aerospace, automotive, and healthcare applications. This demand is fueled by the ability of EBM to produce intricate parts with minimal material wastage. Additionally, continuous advancements in EBM technologies are expanding their capabilities, enhancing precision and enabling the fabrication of complex geometries.

EBM's high precision capabilities and minimal heat-affected zones are further bolstering its appeal, particularly for heat-sensitive and difficult-to-machine materials, where traditional methods struggle. These factors are collectively aiding market expansion, as industries increasingly rely on EBM for their evolving performance requirements. EBM is poised to play a pivotal role in shaping the future of advanced manufacturing in foreseeable future.

However, the market faces challenges such as high initial investment costs, specialized workforce requirements, and limited scalability for mass production compared to traditional methods. To counter these obstacles, industry leaders are developing large-format EBAM systems for additive manufacturing of complex, large-scale components. These initiatives aim to enhance productivity and cost-efficiency while expanding the market's application scope.

Collaborations and partnerships are also pivotal, facilitating knowledge exchange and technological advancements. Investment in research and development is focused on optimizing EBM processes, improving material utilization, and reducing operational expenses.

Additionally, educational initiatives are underway to nurture a skilled workforce adept at leveraging advanced EBM technologies. These proactive measures are crucial for overcoming challenges and solidifying EBM's position as a preferred solution for high-precision manufacturing in demanding industries.

Electron Beam Machining Market Trends

Electron beam machining (EBM) is evolving significantly with advancements in beam control and manipulation, facilitated by sophisticated CNC systems and beam deflection technologies, which are enhancing its precision and enabling the machining of intricate micro-features. Researchers are exploring new beam sources with improved characteristics like higher brightness and better pulse control, promising faster processing times and enhanced material compatibility.

Integration with additive manufacturing is leveraging EBM's precision to produce complex parts with unique geometries that traditional methods struggle to replicate. Environmental considerations are increasingly influencing EBM development, driving efforts to reduce energy consumption and manage waste materials more sustainably.

Segmentation Analysis

The global market is segmented based on type, application, end use, and geography.

By Type

Based on type, the market is segmented into conventional electron beam machining, electron beam melting, electron beam surface treatment, electron beam heating, and others.

The conventional electron beam machining segment led the electron beam machining market in 2023, reaching a valuation of USD 79.8 million. This dominance can be attributed to the established presence and reliability of conventional electron beam machining in producing high-precision components across various industries.

With a proven track record in the aerospace, automotive, and healthcare sectors, conventional EBM continues to be preferred for its capability to machine intricate parts with minimal heat-affected zones and superior material integrity. Its widespread adoption underscores its significance in modern manufacturing, which is solidifying its position as a cornerstone technology driving innovation and efficiency in high-precision machining processes.

By Application

Based on application, the electron beam machining market is classified into welding, drilling, cutting, milling, and others. The welding segment is poised to grow significantly at a robust CAGR of 4.28% through the forecast period. This growth is projected to be driven by increasing product usage across diverse industries for high-precision welding solutions facilitated by electron beam machining technology.

Industries such as aerospace, automotive, and medical devices are increasingly adopting electron beam welding for its ability to produce strong, reliable welds with minimal distortion and superior material integrity. As technological advancements continue to enhance welding capabilities and expand application possibilities, the welding segment is set to play a pivotal role in precision manufacturing, meeting the stringent requirements of modern industrial applications.

By End Use

Based on end use, the market is divided into automotive, aerospace, healthcare, oil & gas, agriculture, and others. The aerospace segment secured the largest revenue share of 30.80% in 2023. The aerospace industry entails stringent requirements for high-precision components that EBM excels in manufacturing. EBM's capability to produce complex, lightweight, and heat-resistant parts crucial for aircraft and spacecraft applications contributes significantly to its adoption in aerospace manufacturing.

As the aerospace sector continues to expand globally, driven by advancements in air travel and space exploration, the demand for EBM technologies is expected to further intensify, solidifying the aerospace segment's leadership in the market.

Electron Beam Machining Market Regional Analysis

Based on region, the global market is classified into North America, Europe, Asia-Pacific, MEA, and Latin America.

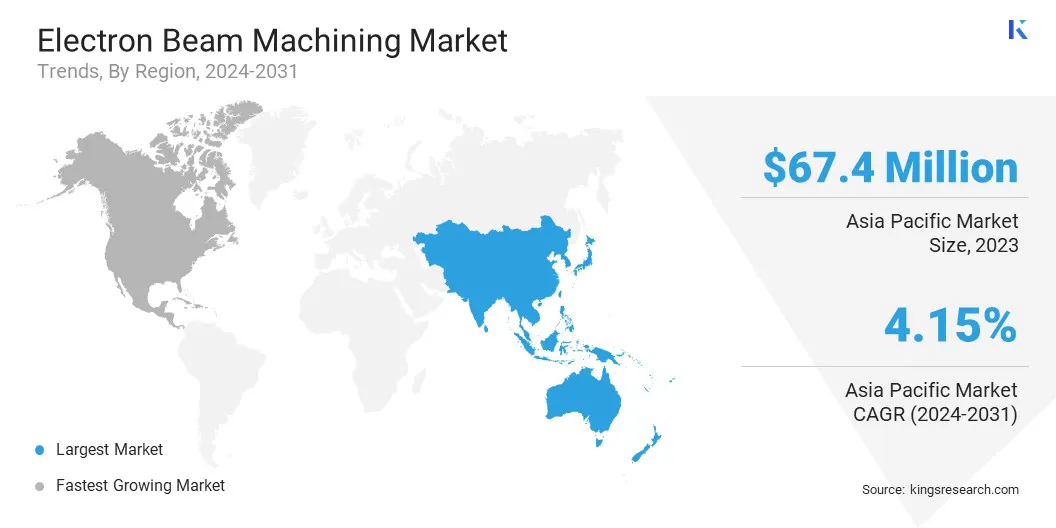

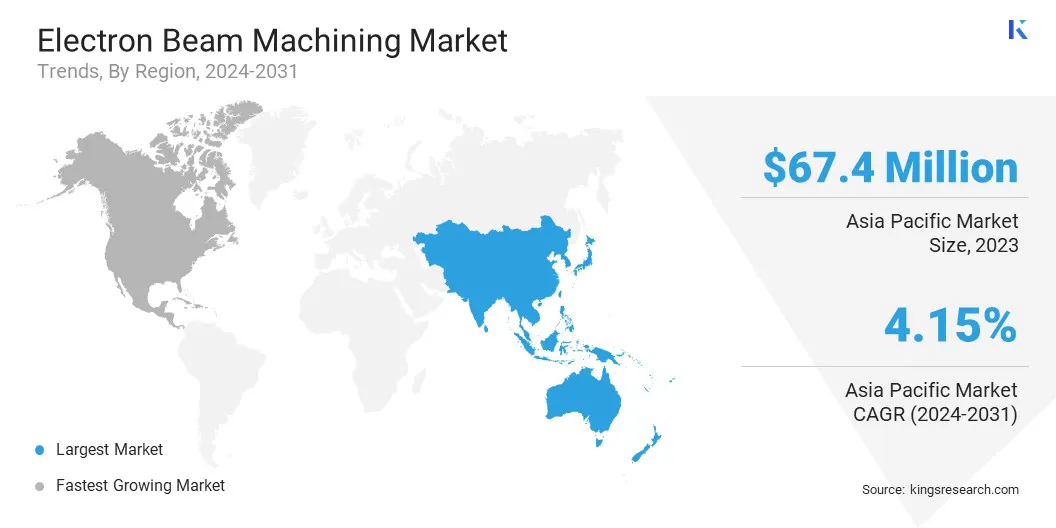

Asia-Pacific electron beam machining market share accounted for 34.48% and was valued at USD 67.4 million in 2023. This leadership is underpinned by robust investments in precision engineering and advanced manufacturing capabilities.

- According to the Singapore Economic Development Board, the country’s precision engineering sector, accounted for 11.8% of the country's manufacturing output and 12.5% of total value-added in 2022.

This exemplifies the region's strategic focus on high-precision industries. Moreover, the region’s rapid industrialization and strategic geographic positioning have fostered a conducive environment for electron beam machining adoption, driving its widespread application across aerospace, automotive, and electronics sectors.

Moreover, North America is positioned to record substantial growth in the electron beam machining market, exhibiting a significant CAGR of 3.54% over the forecast period. This growth is driven by extensive research and development activities focused on enhancing EBM technologies for aerospace and defense applications. Additionally, the region benefits from a strong presence of key players investing in innovative manufacturing processes, including hybrid additive manufacturing integrating EBM.

These advancements are bolstered by the region's robust infrastructure and stringent quality standards, which support the production of high-precision components for critical industries. As the demand for lightweight materials and advanced manufacturing solutions increases, it is likely to strengthen North America's standing in the global market

Competitive Landscape

The electron beam machining market report will provide valuable insight with an emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions.

Strategic initiatives, including investments in R&D activities, the establishment of new manufacturing facilities, and supply chain optimization, could create new opportunities for market growth.

List of Key Companies in Electron Beam Machining Market

- Global Beam Technologies AG

- Mitsubishi Electric Corporation

- Bodycote

- TETA

- FOCUS GmbH

- Evobeam

- pro-beam GmbH

- Cambridge Vacuum Engineering

- Sciaky Inc.

- EB Industries

Key Industry Development

- November 2023 (Product Launch): Sciaky, a renowned 3D printing and beam welding company, launched EBAM-53 system that utilizes electron beam welding system. The machine was intended for use in laboratory and research facilities. The machine has build volume 26-inch cube, thus of requires smaller space for installation and incurs lower operational costs.

The global electron beam machining market is segmented as:

By Type

- Conventional Electron Beam Machining

- Electron Beam Melting

- Electron Beam Surface Treatment

- Electron Beam Heating

By Application

- Welding

- Drilling

- Cutting

- Milling

- Others

By End Use

- Automotive

- Aerospace

- Healthcare

- Oil & Gas

- Agriculture

- Others

By Region

- North America

- Europe

- France

- U.K.

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America