Market Definition

Dairy processing equipment comprises specialized machinery and systems used to handle, process, and package milk and dairy products. It encompasses technologies for pasteurization, homogenization, separation, filtration, evaporation, drying, fermentation, chilling, storage, and packaging. The equipment converts raw milk into finished products such as fluid milk, cheese, yogurt, butter, cream, ice cream, and milk powder.

Dairy Processing Equipment Market Overview

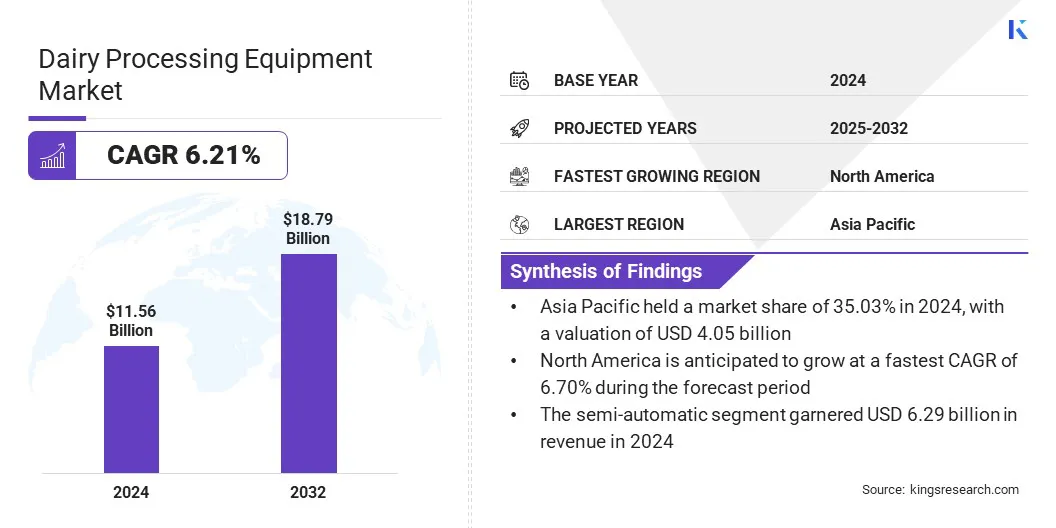

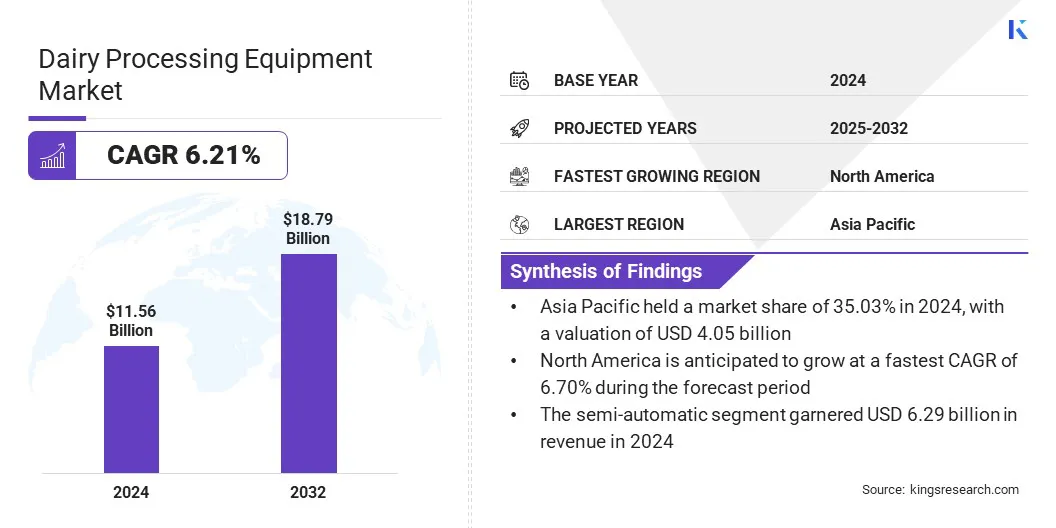

The global dairy processing equipment market was valued at USD 11.56 billion in 2024 and is projected to grow from USD 12.25 billion in 2025 to USD 18.79 billion by 2032, exhibiting a CAGR of 6.21% during the forecast period.

This growth is driven by the rising consumption of value-added dairy products such as cheese, yogurt, and flavored milk, which is creating strong demand for advanced processing solutions. Rapid technological advancements, including automation and smart monitoring systems, are enabling producers to enhance efficiency, maintain product quality, and reduce operational costs.

Key Highlights:

- The dairy processing equipment industry was recorded at USD 11.56 billion in 2024.

- The market is projected to grow at a CAGR of 6.21% from 2025 to 2032.

- Asia Pacific held a share of 35.03% in 2024, valued at USD 4.05 billion.

- The homogenizers segment garnered USD 2.80 billion in revenue in 2024.

- The semi-automatic segment is expected to reach USD 10.38 billion by 2032.

- The cheese segment is anticipated to witness the fastest CAGR of 6.73% through the projection period.

- North America is anticipated to grow at a CAGR of 6.70% over the forecast period.

Major companies operating in the dairy processing equipment market are GEA Group Aktiengesellschaft, Tetra Pak International S.A., ALFA LAVAL, SPX FLOW, Inc., JBT, Krones AG, Feldmeier Equipment, Paul Mueller Company, Scherjon Equipment Holland, Coperion GmbH, Gemak, Neologic Engineers Private Limited, Tessa Dairy Machinery LTD, Repute Engineers Pvt Ltd, and Shanghai Triowin Intelligent Machinery Co. Ltd.

Increasing investment in modern processing facilities is boosting market expansion. Adoption of automation, energy-efficient machinery, and advanced monitoring systems enhances operational efficiency, ensures product safety, and supports the production of value-added dairy products to meet rising consumer demand.

- In October 2024, the U.S. Department of Agriculture (USDA) allocated USD 11.04 million under the Dairy Business Innovation (DBI) Initiatives to help small and mid-sized dairy businessesadopt innovative production and processing techniques, invest in modern dairy processing equipment, and enhance production efficiency.

Market Driver

Increasing Global Milk Production

A major factor fueling the growth of the dairy processing equipment market is the increasing global milk production. Rising volumes, particularly of cow and buffalo milk, are creating greater demand for processing, storage, and packaging equipment.

This demand prompts dairy manufacturers to invest in modern equipment, expand processing capacities, and adopt advanced technologies. It enables processors to maintain product quality, ensure food safety, and meet growing consumer demand.

- According to the Food and Agriculture Organization of the United Nations (FAO) in the Organization for Economic Co-operation and Development–FAO (OECD-FAO) Agricultural Outlook 2025–2034, global milk production is projected to grow by 1.8% annually over the next decade, driven by higher yields per animal and increasing demand for dairy processing equipment.

Market Challenge

Rising Maintenance and Operational Costs of Advanced Machinery

A key challenge in the dairy processing equipment market is the rising maintenance and operational costs of advanced machinery. High energy consumption, frequent replacement of parts, and the need for skilled operators increase production expenses and strain budgets for small and medium-scale dairy processors. These cost pressures can limit the adoption of new technologies and affect the operational efficiency of dairy processors.

To address this challenge, market players are investing in energy-efficient and low-maintenance machinery that reduces overall operating expenses. Companies are implementing predictive maintenance programs, using IoT sensors and real-time monitoring to detect issues before they escalate. Additionally, manufacturers are providing training programs for operators to improve efficiency and reduce errors during processing.

Market Trend

Rising Adoption of Smart Processing Systems

A key trend in the dairy processing equipment market is the rising adoption of smart processing systems. Manufacturers are offering automated machinery equipped with sensors, SCADA, and MIS technologies to monitor production in real time and optimize operations.

These systems enhance efficiency, reduce milk loss, and ensure consistent product quality. This shift prompts innovation in digital dairy equipment, improves safety, and boosts the adoption of advanced, technology-driven solutions across dairy processing facilities.

- In March 2025, Tamil Nadu Cooperative Milk Producers Federation (Aavin) initiated the modernization of its dairy unit at Kottapattu near Trichy International Airport. The upgraded features automated milk processing and packaging, incorporating electric and pneumatic valves, sensors, and SCADA and MIS systems to monitor production, improve milk quality, reduce losses, and ensure safe operations, including for value-added products such as butter and milk cream.

Dairy Processing Equipment Market Report Snapshot

|

Segmentation

|

Details

|

|

By Type

|

Homogenizers, Membrane Filtration Equipment, Separators, Mixing & Blending Equipment, Evaporators & Dryers, Pasteurizers, Others

|

|

By Operation

|

Automatic, Semi-automatic

|

|

By Application

|

Processed Milk, Cheese, Yogurt, Protein Ingredients, Others

|

|

By Region

|

North America: U.S., Canada, Mexico

|

|

Europe: France, UK, Spain, Germany, Italy, Russia, Rest of Europe

|

|

Asia-Pacific: China, Japan, India, Australia, ASEAN, South Korea, Rest of Asia-Pacific

|

|

Middle East & Africa: Turkey, U.A.E., Saudi Arabia, South Africa, Rest of Middle East & Africa

|

|

South America: Brazil, Argentina, Rest of South America

|

Market Segmentation:

- By Type (Homogenizers, Membrane Filtration Equipment, Separators, Mixing & Blending Equipment, Evaporators & Dryers, Pasteurizers, and Others): The homogenizers segment earned USD 2.80 billion in 2024, primarily due to rising demand for consistent milk quality and efficient fat dispersion.

- By Operation (Automatic and Semi-automatic): The semi-automatic segment held a share of 54.39% in 2024, attributed to its widespread use in small and medium-scale dairy processing units due to its cost-effectiveness and operational flexibility.

- By Application (Processed Milk, Cheese, Yogurt, and Protein Ingredients): The processed milk segment is projected to reach USD 5.28 billion by 2032, owing to rising consumer demand for packaged and value-added milk products.

Dairy Processing Equipment Market Regional Analysis

Based on region, the market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and South America.

The Asia-Pacific dairy processing equipment market share stood at 35.03% in 2024, valued at USD 4.05 billion. This dominance is attributed to rapid population growth and rising per capita income, which boost demand for milk and value-added dairy products such as yogurt, cheese, and flavored milk.

Technological advancements, including automation, energy-efficient machinery, and smart monitoring systems, are improving production efficiency, product quality, and operational safety.

Additionally, the expansion of dairy farming and investments in modern processing facilities are supporting the capacity growth of dairy processing operations. Moreover, increasing investment in modern, large-scale processing facilities is supporting regional market expansion in the region.

- In February 2025, Amul inaugurated the world’s largest curd manufacturing plant at Sankrail Food Park, West Bengal, with a daily milk processing capacity of 1.5 million liters.

The North America dairy processing equipment industry is set to grow at a robust CAGR of 6.70% over the forecast period. This growth is propelled by the rising consumer demand for processed and value-added dairy products, such as cheese, yogurt, and flavored milk. Technological advancements, including automation, energy-efficient machinery, and smart processing systems, are enabling higher production efficiency and improved product quality.

Strict food safety and quality regulations are prompting dairy processors to upgrade their equipment to meet compliance standards. Additionally, increasing investment in modern dairy processing facilities and the expansion of large-scale dairy operations are accelerating domestic market growth.

- In March 2024, Maola Local Dairies, a subsidiary of Maryland & Virginia Milk Cooperative Association (MDVA), acquired HP Hood’s UHT dairy processing facility in Philadelphia, Pennsylvania. The acquisition aims to expand Maola’s dairy processing capacity and ensure the continued production of coffee cream, half & half, and other extended shelf-life dairy products.

Regulatory Frameworks

- In the U.S., the Food and Drug Administration (FDA) regulates dairy processing equipment to ensure compliance with food safety and hygiene standards. The agency oversees machinery used for pasteurization, storage, processing, and packaging, monitors sanitation protocols, enforces operational safety, and ensures accurate labeling and consistent product quality across dairy processing facilities.

- In the UK, the Food Standards Agency (FSA) regulates dairy processing equipment by enforcing safety, hygiene, and quality compliance. It monitors pasteurizers, storage tanks, and packaging machinery, supervises sanitation and maintenance practices, ensures traceability, and works to minimize contamination risks, safeguarding consumers and maintaining consistent standards across dairy processing operations.

- In China, the State Administration for Market Regulation (SAMR) regulates dairy processing equipment by enforcing national food safety and quality standards. It monitors the design, manufacturing, and operation of processing machinery, inspects production lines, ensures traceability, and oversees contamination prevention measures, ensuring that dairy products are produced safely and meet technical regulatory requirements.

- In India, the Food Safety and Standards Authority of India (FSSAI) regulates dairy processing equipment to maintain hygiene, safety, and quality standards. The authority oversees pasteurization, homogenization, and packaging equipment, enforces sanitary design, conducts inspections, and ensures proper maintenance, labeling, and storage practices to prevent contamination and protect consumer health.

Competitive Landscape

Major players operating in the dairy processing equipment industry are actively expanding their portfolios through strategic acquisitions to enhance their technological capabilities and expand service offerings. They are securing intellectual property rights and assets to strengthen aftermarket support and engineering services for processing equipment.

Additionally, players are implementing automation and smart monitoring technologies to improve production efficiency, reduce downtime, and ensure consistent product quality.

- In November 2024, Fortifi Food Processing Solutions acquired the intellectual property, customer relationships, and select assets of JWE-BANSS GmbH, a manufacturer of primary protein processing systems, to provide aftermarket parts and engineering support for protein and dairy processing equipment.

Key Companies in Dairy Processing Equipment Market:

- GEA Group Aktiengesellschaft

- Tetra Pak International S.A.

- ALFA LAVAL

- SPX FLOW, Inc.

- JBT

- Krones AG

- Feldmeier Equipment

- Paul Mueller Company

- Scherjon Equipment Holland

- Coperion GmbH

- Gemak

- Neologic Engineers Private Limited

- Tessa Dairy Machinery LTD

- Repute Engineers Pvt Ltd

- Shanghai Triowin Intelligent Machinery Co. Ltd

Recent Developments (Product Launch)

- In June 2025, DuPont launched the FilmTec Hypershell XP RO-8038 reverse osmosis element, enhancing milk, whey, and lactose processing with improved energy efficiency and durability.

- In March 2024, Fortifi Food Processing Solutions launched as a unified global platform consolidating leading brands and products in food processing equipment and automation.