Brush Deburring Machine Market Size

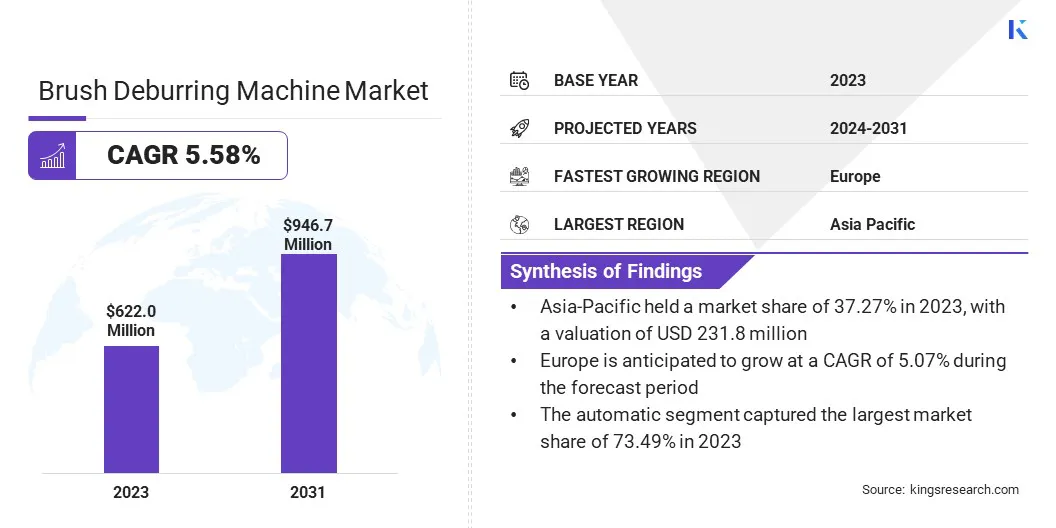

The global Brush Deburring Machine Market size was valued at USD 622.0 million in 2023 and is projected to grow from USD 647.4 million in 2024 to USD 946.7 million by 2031, exhibiting a CAGR of 5.58% during the forecast period. In the scope of work, the report includes products offered by companies such as Peter Wolters, BRUSA & GARBOLI srl, Valgro India Limited, René Gerber AG, Osborn GmbH, KEF-Motor, Murata Machinery, Ltd., KADIA Produktion GmbH + Co, ELMAG Entwicklungs und Handels GmbH, STÜRMER MASCHINEN and others.

The rising development of environmentally friendly deburring processes and materials is driving market growth. The development of environmentally friendly deburring processes and materials is a significant trend in the brush deburring machine market, fueled by the increasing emphasis on sustainability and regulatory compliance.

Manufacturers are innovating their products to reduce the environmental impact of deburring operations by using biodegradable and non-toxic brush materials, as well as implementing dry deburring techniques that eliminate the need for harmful lubricants and coolants.

These eco-friendly approaches minimize waste and pollution and enhance workplace safety by reducing exposure to hazardous substances. The growing shift toward greener solutions is further supported by stringent environmental regulations and the growing corporate commitment to sustainable practices.

As industries such as automotive and aerospace seek to reduce their carbon footprint and adhere to environmental standards, the demand for sustainable deburring solutions is expected to rise. This shift aligns with global sustainability goals and offers companies a competitive edge by appealing to environmentally conscious consumers and stakeholders.

The adoption of eco-friendly deburring technologies is both a strategic and ethical imperative in the modern industrial landscape. A brush deburring machine is a specialized equipment used to remove burrs, sharp edges, and other imperfections from metal and plastic components through the action of rotating brushes.

These machines play a crucial role in the finishing process of manufacturing, ensuring that components meet precise quality and safety standards. Brush deburring machines are classified into three main types: automatic, semi-automatic, and manual.

Automatic machines offer high efficiency and consistency, making them suitable for large-scale production lines, while semi-automatic machines provide a balance between automation and manual intervention, often used in medium-scale operations. Manual brush deburring machines are typically employed in small-scale operations or for parts that require a high degree of manual finesse.

The applications of brush deburring machines are diverse, encompassing industries such as automotive, aerospace, electronics, and medical devices. They are used to finish components such as gears, shafts, and surgical instruments, thereby ensuring these parts are free from sharp edges that could cause mechanical failure or injury.

Analyst’s Review

The brush deburring machine market is experiencing robust growth due to the increasing demand for high-precision components across various industries, including automotive, aerospace, and electronics. The trend toward automation and Industry 4.0 is significantly influencing market dynamics, as manufacturers seek to enhance productivity and efficiency through advanced deburring solutions.

Key market players are adopting several strategic imperatives to maintain and enhance their competitive edge. A major strategy involves investing heavily in research and development to innovate and improve deburring technologies, with a major focus on increasing automation, enhancing precision, and developing environmentally friendly processes. Additionally, companies are expanding their product portfolios to offer customized solutions tailored to specific industry needs.

Manufacturers are seeking to establish strategic partnerships and collaborations to leverage technological expertise and expand their market reach. Additionally, key players are focusing on expanding their global footprint through mergers, acquisitions, and establishing new production facilities in emerging markets.

Emphasizing customer support and training services is also crucial, ensuring clients can maximize the utility of their deburring machines. These strategies are essential for sustaining growth and addressing the evolving demands of the brush deburring machine market.

What are the major factors affecting this market?

The rise of Industry 4.0 and smart manufacturing has significantly increased the demand for automated deburring solutions. Industry 4.0, characterized by the integration of cyber-physical systems, the Internet of Things (IoT), and cloud computing into manufacturing processes, aims to create highly efficient, interconnected, and flexible production environments.

Automated deburring machines, equipped with advanced sensors and AI-driven controls, align perfectly with these goals by enhancing precision, reducing manual labor, and minimizing errors.

These machines are seamlessly integrated into smart factories, enabling remote monitoring and control, allowing for real-time adjustments and predictive maintenance. This level of automation boosts productivity and ensures consistent product quality, which is critical in industries such as automotive and aerospace where precision is paramount.

Furthermore, the data collected from these automated systems undergoes analysis to optimize processes, predict potential issues, and improve overall operational efficiency. As manufacturers strive to maintain competitiveness in a rapidly evolving market, the adoption of automated deburring solutions driven by Industry 4.0 technologies is becoming increasingly essential.

The skilled labor shortage presents a significant challenge impeding the development of the brush deburring machine market. Operating and maintaining advanced deburring machines require a high level of technical expertise, which is becoming increasingly difficult to find in many regions. The shortage is exacerbated by the aging workforce in the manufacturing sector and the insufficient influx of new, trained personnel.

This gap impacts the efficiency and productivity of manufacturing operations, as companies struggle to find qualified operators who maximize the capabilities of sophisticated deburring equipment. The lack of skilled labor hinders the adoption of advanced technologies, as companies may be reluctant to invest in new machines if they cannot ensure proper operation and maintenance.

Additionally, the need for continuous training and upskilling of existing workers adds to operational costs. Addressing this challenge requires a multi-faceted approach, including investing in training programs, partnering with educational institutions, and promoting manufacturing careers to younger generations.

By developing a robust pipeline of skilled workers, industry players are striving to meet the growing demand for high-precision manufacturing and advanced deburring solutions.

What are the major technological trends in this market?

Integrating the Internet of Things (IoT) with brush deburring machines is a transformative trend reshaping the industry. IoT technology enables these machines to be interconnected with other manufacturing equipment and systems, facilitating real-time data exchange and enhanced operational control.

By embedding sensors and connectivity features, IoT-integrated deburring machines monitor their own performance, detect anomalies, and predict maintenance needs before breakdowns occur, thus minimizing downtime and extending machine life.

This connectivity allows for continuous optimization of the deburring process, as data analytics possess the capability to identify inefficiencies and suggest improvements. Moreover, IoT integration supports remote monitoring and control, enabling manufacturers to manage operations across multiple sites from a central location. This is particularly beneficial in large-scale operations where consistent quality and uptime are critical.

The ability to gather and analyze data from IoT-enabled deburring machines further supports compliance with quality standards and regulatory requirements by providing comprehensive documentation of the manufacturing process. As IoT technology continues to evolve, its integration into brush deburring machines is likely to enhance efficiency, reliability, and overall productivity.

Segmentation Analysis

The global market is segmented based on type, application, and geography.

What is the market share of the automatic segment?

Based on type, the market is segmented into manual and automatic. The automatic segment captured the largest brush deburring machine market share of 73.49% in 2023. Automatic brush deburring machines offer superior efficiency, consistency, and speed compared to their manual and semi-automatic counterparts. These machines are equipped with advanced technologies such as CNC controls and robotic arms.

These technologies facilitate precise and repeatable deburring operations, which are crucial for maintaining high-quality standards in mass production environments. The automotive and aerospace industries, in particular, benefit from these machines due to their need for high precision and large-scale production capabilities.

Additionally, the integration of automatic deburring machines into smart manufacturing and Industry 4.0 frameworks allows for seamless operation and monitoring, thereby enhancing productivity and reducing downtime.

The rising labor costs and the ongoing skilled labor shortage further foster the shift toward automation, as companies increasingly seek to minimize reliance on manual labor.

Furthermore, the ability of automatic machines to handle complex geometries and multiple types of materials with minimal human intervention makes them highly attractive for modern manufacturing processes.

How fast will the automotive segment grow in this market?

Based on application, the brush deburring machine market is classified into manufacturing, automotive, aerospace, military, and others. The automotive segment is poised to record a staggering CAGR of 6.21% through the forecast period. The automotive industry is undergoing rapid technological advancements and increasing production volumes, highlighting the need for high precision and quality in manufacturing processes.

Brush deburring machines are essential for finishing critical automotive components such as engine parts, gears, and transmission systems, ensuring they meet stringent quality and performance standards. The growing demand for electric vehicles which require even higher precision due to their complexity and performance requirements is likely to propel the market.

Additionally, the trend toward lightweight materials and advanced manufacturing techniques in automotive production necessitates the use of sophisticated deburring technologies to handle diverse materials and intricate designs.

The rising emphasis on automation and smart manufacturing within the automotive sector further contributes to this growth, as companies increasingly invest in advanced deburring solutions to enhance efficiency, reduce production time, and ensure consistent quality.

What is the market scenario in Asia-Pacific and Europe region?

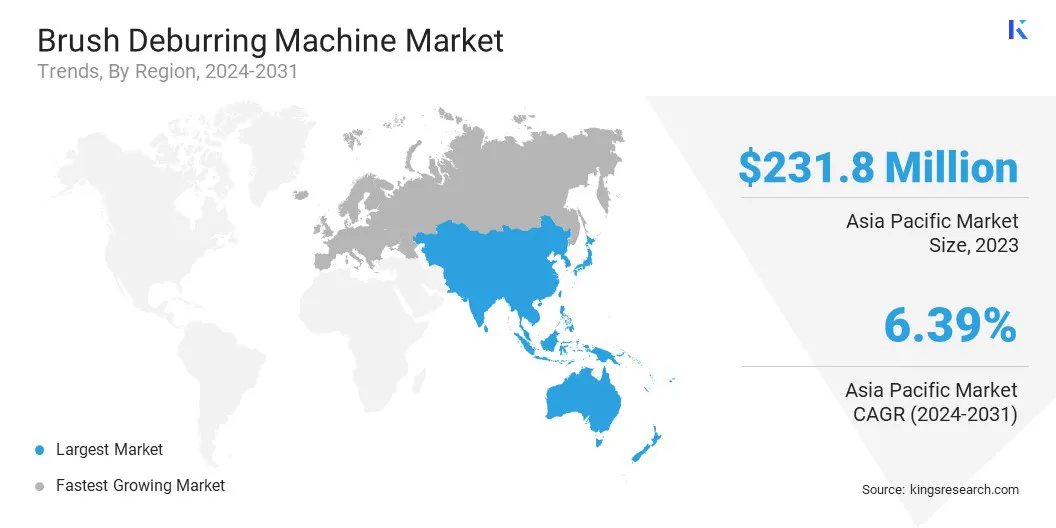

Based on region, the global market is classified into North America, Europe, Asia Pacific, MEA, and Latin America.

Asia-Pacific brush deburring machine market accounted for a significant share of 37.27% and was valued at USD 231.8 million in 2023. This growth is largely attributed to the rapid industrialization and expansion of the manufacturing sector in countries such as China, India, and Japan. The region's robust automotive, aerospace, and electronics industries lead to an increasing demand for high-precision manufacturing equipment, including brush deburring machines.

Additionally, the growing adoption of automation and advanced manufacturing technologies in these industries boosts regional market growth. The presence of numerous manufacturing hubs and the increasing focus on improving product quality and operational efficiency contribute to the high demand for automated deburring solutions.

Moreover, government initiatives and investments aimed at strengthening industrial capabilities and promoting smart manufacturing practices are fostering the adoption of advanced deburring technologies in the region.

Europe is projected to grow at a robust CAGR of 5.07% in the forthcoming years. The region's well-established automotive and aerospace industries are supporting this growth, as these sectors require high-precision deburring solutions to meet stringent quality and safety standards.

Additionally, the increasing adoption of Industry 4.0 and smart manufacturing practices across Europe is spurring the demand for advanced deburring machines that offer automation, efficiency, and precision.

European manufacturers are further focusing on sustainability and eco-friendly production processes, thereby fostering the development and adoption of environmentally friendly deburring technologies.

Furthermore, ongoing investments in research and development, coupled with supportive government policies aimed at enhancing industrial productivity and innovation, are boosting regional market expansion. The presence of leading manufacturing companies and the continuous advancement in manufacturing technologies further play a significant role in propelling the growth of the Europe brush deburring machine market.

Competitive Landscape

The brush deburring machine market report will provide valuable insight with an emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions.

Manufacturers are adopting a range of strategic initiatives, including investments in R&D activities, the establishment of new manufacturing facilities, and supply chain optimization, to strengthen their market standing.

Key Companies in Brush Deburring Machine Market

- Peter Wolters

- BRUSA & GARBOLI srl

- Valgro India Limited

- René Gerber AG

- Osborn GmbH

- KEF-Motor

- Murata Machinery, Ltd.

- KADIA Produktion GmbH + Co

- ELMAG Entwicklungs und Handels GmbH

- STÜRMER MASCHINEN

The global brush deburring machine market is segmented as:

By Type

By Application

- Manufacturing

- Automotive

- Aerospace

- Military

- Others

By Region

- North America

- Europe

- France

- U.K.

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America