Brake Lathe Machine Market Size

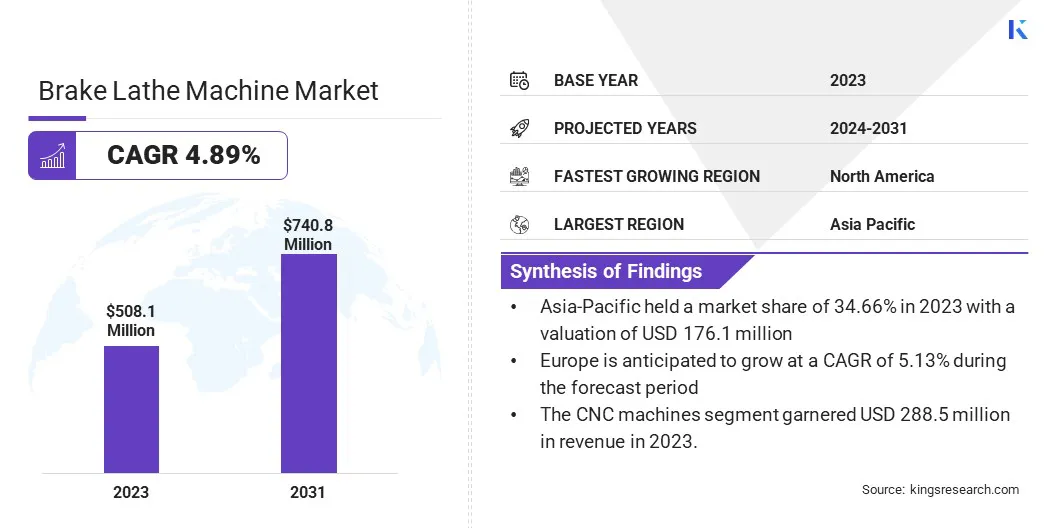

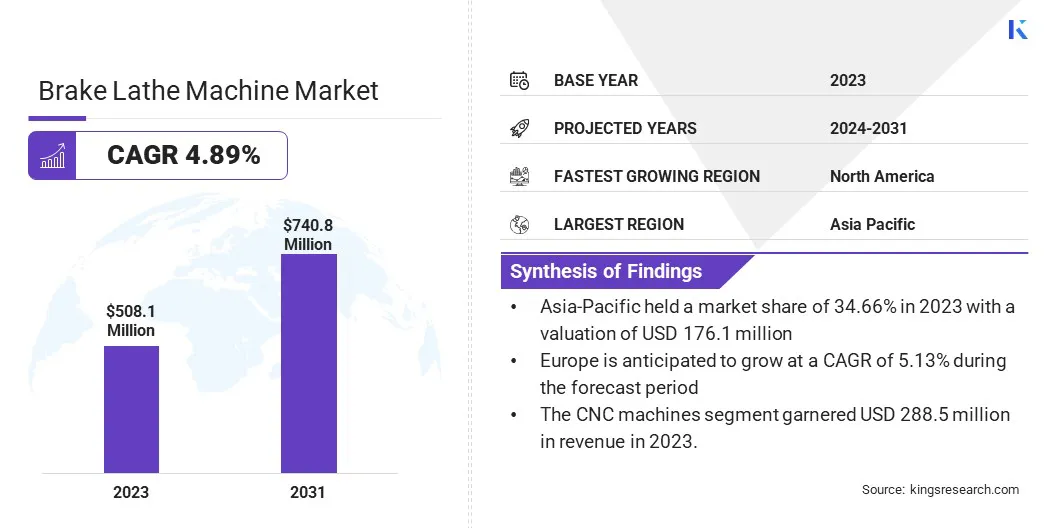

The global Brake Lathe Machine Market size was valued at USD 508.1 million in 2023 and is projected to grow from USD 530.2 million in 2024 to USD 740.8 million by 2031, exhibiting a CAGR of 4.89% during the forecast period.

In the scope of work, the report includes solutions offered by companies such as Accu Turn, Atlas Automotive Equipment, Auto Master, BendPak Inc., Hunter Engineering Company., Pro-Cut International, Spin S.r.l., COMEC Srl, MULTIPRO MACHINES PVT. LTD., SVI INTERNATIONAL, INC. and others.

The growth of the brake lathe machine market is primarily driven by increasing automotive production globally, along with the growing demand for aftermarket automotive services. Moreover, technological advancements in brake lathe machines are leading to improved efficiency and precision, thus contributing to market growth.

Additionally, stringent regulations regarding vehicle safety and maintenance are supporting the widespread adoption of advanced brake lathe machines. The expansion of the market is further fueled by the rising need for vehicle maintenance due to the aging vehicle fleet in developed economies.

The global market involves the production and distribution of machinery crucial for resurfacing brake rotors and drums in automotive applications. These machines are indispensable for upholding vehicle safety and functionality by ensuring proper brake operation. Various manufacturers offer diverse brake lathe machines tailored to different vehicle types and sizes.

Geographically, the market exhibits significant potential, especially in emerging economies witnessing robust growth in their automotive sectors.

Brake lathe machines utilize machining or turning techniques to remove a thin layer of material from the surface of brake rotors and drums, thereby eliminating irregularities such as grooves or warping caused by friction and heat during braking. Brake lathes play a crucial role in automotive workshops, repair shops, and manufacturing facilities by ensuring optimal brake performance and safety.

Moreover, the market is influenced by several factors such as the ongoing trends in automotive production, technological innovations, regulatory standards, and consumer demand for reliable brake maintenance solutions.

Analyst’s Review

Manufacturers in the industry are making efforts to enhance precision and efficiency. New products featuring advanced automation, digital controls, and eco-friendly designs are gaining significant traction. There is an increasing focus on modular designs, upgradable features, and comprehensive training programs to meet evolving customer needs.

These strategies reflect the evolving nature of the market, characterized by technological innovations and a growing emphasis on sustainability and user experience.

Brake Lathe Machine Market Growth Factors

The increasing emphasis on vehicle safety and maintenance is a key factor boosting market expansion, as consumers are becoming more aware of the importance of regular brake maintenance for safe driving, resulting in a growing demand for advanced brake lathe machines.

Manufacturers are responding to this rising demand by developing innovative technologies that enhance precision and efficiency in resurfacing brake components. Additionally, regulatory standards requiring regular vehicle inspections boost the adoption of brake lathe machines.

This trend is expected to continue due to the ongoing emphasis on safety, thereby fostering the growth of the brake lathe machine market.

The rapid technological advancements, leading to shorter product lifecycles, present a key challenge to market development. Manufacturers are focusing on modular designs and upgradable features in brake lathe machines to address this challenge. The incorporation of easily replaceable and upgradable modular components enables the extension of product lifespan, thus providing consumers with cost-effective solutions.

Moreover, providing comprehensive training programs and technical support to users enhances machine usability and facilitates efficient maintenance, thus ensuring that consumers remain well-informed about evolving technologies in the brake lathe machine market.

Brake Lathe Machine Industry Trends

The integration of digital technologies is gaining prominence in the market, with manufacturers incorporating features such as digital displays, automated controls, and connectivity options into their brake lathe machines.

This initiative aimed at enhancing user experience, improving operational efficiency, and enabling remote monitoring and diagnostics. Digital integration further facilitates data collection and analysis, allowing businesses to optimize maintenance schedules and predict potential issues proactively.

As digitalization continues to evolve, brake lathe machines are evolving into smarter and more interconnected systems, aligning with the broader industry shift toward digital transformation.

The increasing focus on environmental sustainability has prompted manufacturers to develop eco-friendly brake lathe machines that minimize waste generation, reduce energy consumption, and employ recyclable materials.

This trend is further fueled by growing environmental awareness among consumers and regulatory pressure to adopt sustainable practices. Eco-friendly brake lathe machines reduce carbon footprints and appeal to environmentally conscious customers and businesses.

As sustainability increasingly influences purchasing decisions, manufacturers are constantly innovating to develop greener solutions that align with market expectations and contribute to a more sustainable automotive industry.

- The Brake Beaver DL-1000, a product of Moto Solutions Corp., was specifically designed to resurface heavy-duty brake drums in trucks, trailers, buses, and similar applications with drum brakes. Its eco-friendly design eliminated the need to discard brake drums, promoting environmental sustainability. It ensures optimal brake performance, prolonges part life, and enhances safety with full seating and 100% contact between components, thus reducing stopping distances.

Segmentation Analysis

The global market is segmented based on machine type, vehicle types, and geography.

By Machine Type

Based on machine type, the market is categorized into CNC machines and conventional machines. The CNC machines segment led the brake lathe machine market in 2023, reaching a valuation of USD 288.5 million. This expansion is primarily fueled by advancements in automation and precision engineering.

CNC (Computer Numerical Control) machines offer higher accuracy, efficiency, and flexibility compared to conventional machines, making them increasingly preferred in automotive workshops and manufacturing facilities.

The ability of CNC machines to perform complex machining operations with minimal manual intervention improves productivity and quality, leading to their increased adoption. Additionally, as industries prioritize technological integration for enhanced performance, CNC machines are expected to continue to lead the market due to their advanced capabilities.

By Vehicle Types

Based on vehicle type, the brake lathe machine market is classified into passenger vehicles and heavy vehicles. The heavy machines segment is poised to witness significant growth, registering a CAGR of 5.83% through the forecast period (2024-2031). This considerable growth is attributed to various factors such as increasing infrastructure development projects, rising demand for commercial transportation, and advancements in heavy vehicle technologies.

Heavy vehicles, including trucks, buses, and construction equipment, require robust brake systems and maintenance, creating a substantial demand for brake lathe machines.

Moreover, regulatory standards mandating regular inspections and maintenance for heavy vehicles contribute to the expansion of the segment. As industries reliant on heavy vehicles continue to grow, the demand for brake lathe machines in this segment is likely to increase steadily.

Brake Lathe Machine Market Regional Analysis

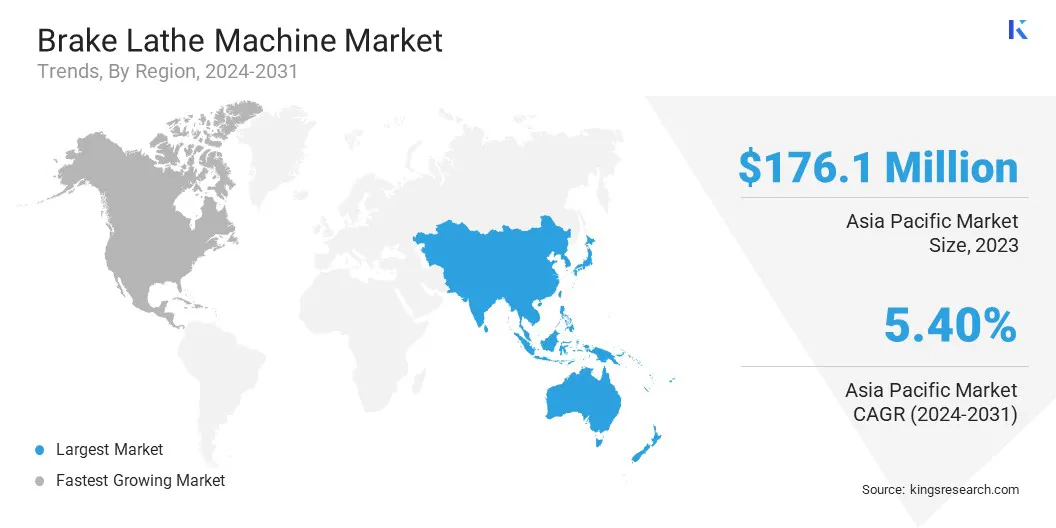

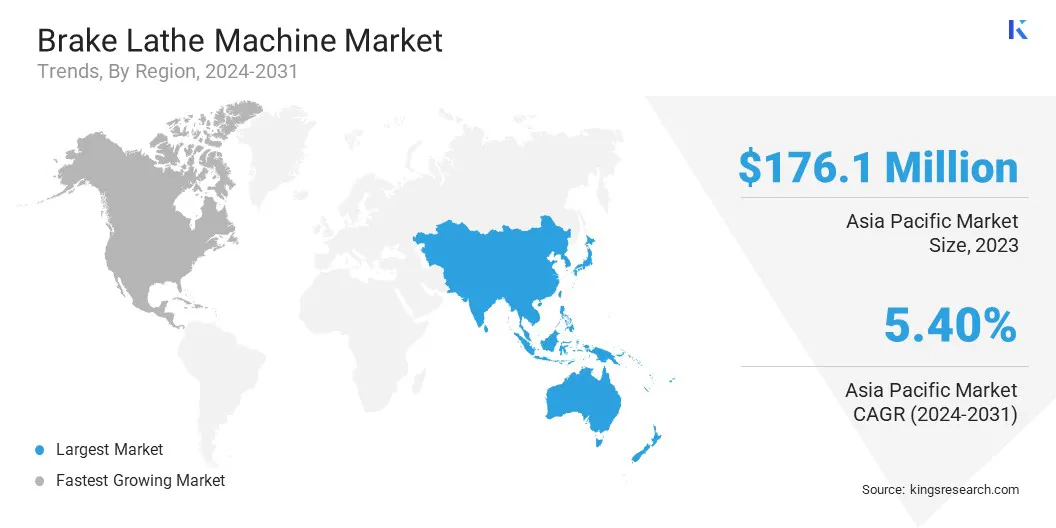

Based on region, the global market is classified into North America, Europe, Asia Pacific, MEA, and Latin America.

Asia-Pacific Brake Lathe Machine Market share stood around 34.66% in 2023 in the global market, with a valuation of USD 176.1 million. This dominance is largely attributed to the presence of major automotive manufacturers and a rapidly expanding automotive aftermarket sector, resulting in increased demand for brake lathe machines.

Additionally, favorable government initiatives aimed at promoting automotive industry growth, coupled with increasing investments in infrastructure development, boost regional market expansion.

Moreover, a large population and rising disposable incomes in countries such as China and India fuels vehicle ownership, leading to strong demand for brake maintenance services and equipment, including brake lathe machines.

- According to the International Monetary Fund (IMF), India has showcased remarkable economic growth over the past decade, maintaining resilience in the face of global challenges. Despite a severe pandemic-induced recession, India's GDP remained robust compared to other major economies. This stands in contrast to China, which has faced slowing growth and economic challenges due to its zero-COVID policy. As global manufacturing has diversified beyond China, India is set to observe significant growth, projecting a 6.8% growth rate from 2021 to 2027, leading among major economies.

Europe is likely to witness steady growth, registering a CAGR of 5.13% over the forecast period. This remarkable growth is mainly fueled by the region's burgeoning automotive industry. Stringent regulatory standards emphasizing vehicle safety and maintenance create a robust market for brake lathe machines.

Additionally, technological advancements in the automotive sector, such as the adoption of electric vehicles (EVs) and advanced braking systems, drive the need for specialized maintenance equipment such as brake lathes.

Furthermore, increasing investments in sustainable transportation solutions and the growing popularity of shared mobility services contribute to the steady demand for brake lathe machines in Europe.

Competitive Landscape

The brake lathe machine market report will provide valuable insight with an emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions.

Manufacturers are adopting a range of strategic initiatives, including investments in R&D activities, the establishment of new manufacturing facilities, and supply chain optimization, to strengthen their market standing.

List of Key Companies in Brake Lathe Machine Market

- Accu Turn

- Atlas Automotive Equipment

- Auto Master

- BendPak Inc.

- Hunter Engineering Company.

- Pro-Cut International

- Spin S.r.l.

- COMEC Srl

- MULTIPRO MACHINES PVT. LTD.

- SVI INTERNATIONAL, INC.

Key Industry Developments

- July 2023 (Expansion): BendPak, Inc.expanded into new products and markets,developing a large light industrial space in Mobile County, Ala. The BendPak Industrial Complex, situated near its East Coast campus, comprises multi-use buildings for manufacturing, assembly, product testing, and distribution. The facility is strategically designed with advanced logistics systems in order to fulfil BendPak’s aim to streamline supply chain operations and expedite customer deliveries.

- April 2023 (Launch): Hunter integrated its ACE on-car brake lathe was integrated with HunterNet 2, a platform designed to provide actionable data for undercar service operators, thus, enhancing operational insights. The inclusion of the DigiCal feature enabled online monitoring of rotor cuts, runout measurements, lathe usage counts, and ROI tracking. This connectivity facilitated 24/7 consumable ordering and access to user manuals. The ACE lathe's innovative technology ensured high-speed rotor servicing without compromising quality, while the tablet interface simplified vehicle-specific data retrieval and real-time comparison, thereby enhancing efficiency and accuracy for technicians.

The Global Brake Lathe Machine Market is Segmented as:

By Machine Type

- CNC Machines

- Conventional Machines

By Vehicle Types

- Passenger Vehicles

- Heavy Vehicles

By Region

- North America

- Europe

- France

- U.K.

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America