Renewable energy systems and off-grid applications demand energy storage solutions that operate reliably under harsh thermal conditions. High-temperature batteries, capable of functioning efficiently at elevated temperatures, present a compelling option for remote installations and systems exposed to heat stress. This blog explores the technical principles, deployment examples, advantages, limitations, and future prospects of high-temperature batteries in renewable energy and off-grid settings.

According to Kings Research estimates, the global high temperature battery market is projected to grow from USD 10.3 billion in 2024 to USD 15.9 billion by 2031, reflecting a CAGR of 6.45% over the forecast period. This steady growth highlights increasing demand for heat-tolerant energy storage solutions in renewable and off-grid applications, driven by industrial decarbonization, off-grid electrification, and integration with thermal energy systems.

How High-Temperature Chemistries Enable Reliable Energy Storage

High-temperature batteries typically rely on molten or solid electrolytes that maintain ionic conductivity at elevated temperatures. Molten salt or molten metal chemistries, for example, employ molten electrolytes that become conductive only when operated at high temperature. An example is the sodium–sulfur (NaS) battery, which functions between 300 °C and 350 °C. Such systems leverage internal thermal energy to maintain the electrolyte in molten form.

In contrast, solid-state thermal batteries use phase change materials or thermally activated electrochemistry to store energy in heat form until conversion back to electricity. The U.S. ARPA-E program supports research into solid-state thermal batteries for coupling intermittent renewables to storage systems.

Thermal battery systems require robust insulation and heat retention mechanisms. The internal heat must be sustained to prevent solidification of the electrolyte during idle periods. Engineering challenges include thermal cycling stresses, material degradation under high temperatures, and sealing against reactive materials.

Applications in Renewable Energy and Off-Grid Systems

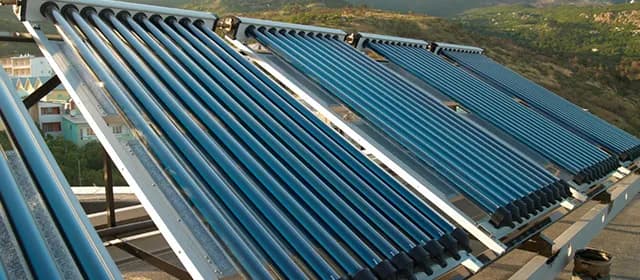

Remote or off-grid solar and wind installations frequently face temperature extremes. Conventional lithium-ion or aqueous battery systems degrade rapidly under heat stress. High-temperature batteries can maintain performance in environments where ambient temperature or solar irradiation elevates system temperature. Industrial-scale thermal batteries, sometimes called “heat batteries,” store thermal energy generated from renewable electricity and release heat later. Renewable Thermal credits their decoupling of heat generation and demand, enabling industrial processes or heating loads to rely on renewable heat sources when needed. (Source: www.renewablethermal.org)

Utilities and off-grid microgrids may benefit from thermal battery integration into hybrid systems. For example, TES systems can act as grid-coupled or off-grid storage, charging when electricity is economical and discharging as heat later, reducing reliance on fossil fuel backup. The Energy Innovation report describes industrial thermal battery deployment enabling continuous process heat from intermittent renewable sources in off-grid settings. (Source: energyinnovation.org)

A notable deployment is the “sand battery” developed by Polar Night Energy for district heating in Finland. The system stores excess renewable electricity as heat in granular sand material at high temperature and delivers it over time to district heating networks. The sand battery’s operational temperature range enables storage over seasonal cycles while sustaining demand in heating systems.

In battery container systems for electricity storage, TESVOLT introduced a “high-temperature cell” variant in their outdoor commercial systems. The solution employs lithium iron phosphate (LFP) cells that tolerate higher temperature ranges and eliminate the need for liquid cooling in certain climates.

What are the Advantages of High-Temperature Batteries?

High-temperature batteries offer higher energy density per volume when the design permits elevated charge and discharge rates under thermal support. The elevated internal temperature improves ionic mobility in the electrolyte, reducing internal resistance. The capacity for passive heat retention reduces active cooling requirements, improving net efficiency in hot climates.

Deployment in remote or desert regions with high ambient temperatures favors systems inherently tolerant of heat extremes. Integration with thermal loads (industrial heat, district heating) offers dual use: storing and delivering thermal energy directly, reducing conversions. Some thermal battery configurations offer better long-duration storage potential, spanning diurnal or seasonal cycles.

Limitations and Challenges:

High operating temperatures impose severe constraints on materials stability, sealing, and thermal management. Thermal cycling leads to mechanical fatigue, expansion mismatch, and degradation. Maintaining internal temperature during idle periods demands high-grade insulation, which increases cost and mass. Start-up energy to reheat the system after shutdown reduces energy efficiency. Safety concerns escalate because of reactive molten materials, leakage, and thermal runaway risk. Application outside stationary or heating-integrated systems is limited: mobile systems like electric vehicles cannot tolerate sustained high internal temperature. Efficiency penalties exist in the conversion between stored thermal energy and electricity in hybrid systems.

Further, few government sources provide field data on long-term reliability under real operating conditions. Research labs such as NREL emphasize that battery thermal performance under elevated stress is central to lifetime and safety evaluation. (Source: www.nrel.gov)

Most deployment examples focus on stationary or thermal applications rather than pure electrical off-grid systems. Commercial adoption remains nascent relative to conventional battery systems. Scaling to gigawatt-hour volumes faces supply chain constraints and cost hurdles tied to high specification materials and insulation systems.

Design Considerations and System Integration:

Integration of high-temperature batteries into renewable energy systems demands co-design of thermal insulation, heat retention, and electrical conversion subsystems. A hybrid architecture may store energy as heat initially and convert it to electricity through thermoelectric, thermophotovoltaic, or Stirling engine modules. System engineers must optimize the balance between thermal loss, conversion efficiency, and material cost.

Thermal modelling is critical. Designers must simulate heat loss rates, startup energy for reheating, and the impact of ambient temperature fluctuations. The design must ensure uniform temperature distribution to prevent thermal stress gradients. Material choices such as high-temperature ceramics, alloys, and composite insulators affect overall durability and cost.

Maintenance regimes differ from conventional batteries. Inspection must focus on insulation degradation, seal integrity, and electrode condition under thermal cycling. Cycle life prediction depends on electrochemical factors as well as thermal fatigue characteristics.

For off-grid systems, coupling with renewable generation sizing is important. Storage duration, discharge rate, and thermal loss rates influence capacity planning. In remote installations, passive solar gain or waste heat integration may reduce heating requirements.

Emerging Trends and Future Opportunities for High-Temperature Energy Storage

Research into advanced solid-state thermal batteries and hybrid electro-thermal storage may expand the viability of high-temperature systems. ARPA-E’s support for solid-state thermal battery development suggests potential breakthroughs in coupling heat storage with electricity output.

Advances in high-temperature materials, such as ceramics and thermally stable electrolytes, may reduce insulation burden and enhance cycle life. Scalability requires cost reductions in materials and manufacturing techniques. Improving heat retention and reducing startup energy deficits remain key engineering goals.

Regulatory support or incentives for thermal storage, especially in industrial decarbonization, may accelerate adoption. Integration with district heating grids or industrial processes enables commercial value beyond mere electricity storage. The sand battery model illustrates synergy between thermal storage and distributed heating infrastructure.

Hybridization with conventional batteries may yield systems that accept high-temperature storage for base load or slow cycles while using lithium or other batteries for rapid response. Optimization of multi-vector energy storage (heat and electricity) may emerge as a design paradigm in off-grid and renewable systems.

Conclusion

High-temperature batteries represent a promising niche where heat tolerance and thermal energy integration provide distinct advantages for renewable and off-grid deployments. Their ability to sustain elevated internal temperatures, integrate directly with thermal loads, and withstand harsh ambient conditions positions them for applications that conventional batteries struggle to serve.

Material, insulation, thermal cycling, and system design challenges remain significant barriers. Commercial deployment currently concentrates on thermal storage and stationary grid roles rather than pure off-grid electrical systems. Continued research, material innovation, and hybrid system strategies will determine whether high-temperature batteries mature into a widespread component of the energy transition.