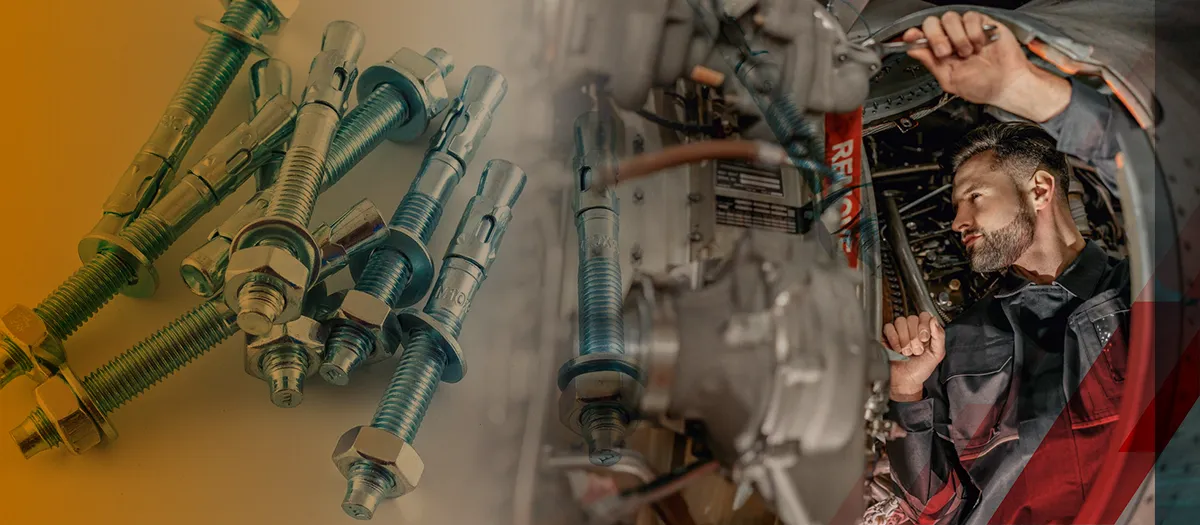

If you've ever traveled by airplane, you've likely been captivated by the seamless experience. Have you ever wondered how aircraft are made? What are the components that bind each of its parts together? The answer lies in aerospace fasteners, an unsung champion of the aerospace industry. It is the game-changer that is reshaping the aerospace structure.

So, fasten your seatbelts for a ride in space with this tiny marvel of aircraft.

What are Aerospace Fasteners?

Aerospace fasteners, or aircraft fasteners, are essential components used in the production of aerostructures for commercial and military aircraft. These fasteners play a crucial role in joining various aircraft parts into a complete airplane during the final assembly process. They are designed to meet the stringent safety and weight requirements of the aerospace industry, ensuring durability and the ability to withstand high gravity pressures.

Aircraft fasteners are used in assembling aerostructures such as the fuselage, wings, empennage, nose, pylon, nacelle, and flight control surfaces. According to a recent study by Kings Research, the global aerospace fastener market is expected to reach $11.39 billion in revenue by 2030.

How do Aerospace Fasteners Work?

Aerospace fasteners, such as Dzus fasteners, are extensively used in the aerospace sector. Dzus fasteners have a stud with a groove or slot connected to a spring-loaded mechanism, which provides a secure & quick fastening solution for aircraft components.

Similarly, aircraft screws are commonly used in aircraft. These screws have external threads and are pointier with a higher helical ridge, providing a secure fastening solution for various aircraft components.

Various types of fasteners are used in a wide range of aerospace applications, including commercial jets, defense, and aerospace land vehicles, wherein they are crucial for maintaining the structural integrity of these projects.

Understanding the Types of Aerospace Fasteners

Aircraft fasteners encompass a diverse range of components designed to meet specific demands. Some of the main types include:

- Bolts and Screws: Bolts and screws are essential for securing various components of an aircraft. They are manufactured with high-quality steel and undergo special treatments to enhance their heat resistance, corrosion resistance, and ability to withstand vibrations.

- Rivets: Rivets are extensively used in aircraft construction to join structural components. They are designed to provide secure and durable connections, contributing to the overall strength and stability of the aircraft.

- Nuts: Nuts are used in conjunction with bolts to secure components together. They are manufactured to meet high-strength and precision standards, ensuring reliability and safety in aerospace applications.

- Washers: Washers play a critical role in distributing the load of fasteners and preventing damage to the aircraft's components. Different types of washers, including lock washers, are used to meet specific aerospace hardware requirements.

Exploring the Major Benefits of Aerospace Fasteners

Aircraft fasteners offer a wide range of advantages in aerospace applications. Some of the major benefits include:

- Aircraft fasteners offer speed in production processes, contributing to efficient assembly and manufacturing.

- The fasteners provide a net or near-net shape, reducing the need for extensive secondary operations and streamlining the manufacturing process.

- They ensure consistency and dimensional accuracy, contributing to the precision and reliability of aircraft components.

- They deliver high-quality surface finishes, meeting the stringent standards of the aerospace industry.

- The fasteners in aerospace contribute to material savings and minimize scrap, optimizing resource utilization in aircraft manufacturing.

- They enhance mechanical properties, leading to a greater strength-to-weight ratio and unbroken grain flow in aerospace components.

Unveiling the Novel Innovations in Aerospace Fasteners

In recent years, the aerospace industry has seen significant innovations in the design, manufacturing, and application of specialized aircraft fasteners. Some notable innovations include:

1. Specialized Aerospace Fasteners

Manufacturers like Fastener Innovation Technology, Inc. have been at the forefront of designing, prototyping, testing, evaluating, and manufacturing specialized aerospace fasteners. These companies are gaining customer attention by setting the standard for specialty precision fasteners. The range of high-end fasteners includes single-piece threaded bolts, multi-piece assemblies, screws, nuts, shear pins, quick-release assemblies, and build-to-print specials. These innovations have been crucial in providing high-quality, tailored fastening solutions for specific aerospace applications.

2. R&T Roadmap for the Fastener Segment

Companies such as LISI AEROSPACE have prioritized maintaining a high level of activity in the fastener domain, driven by commercial aviation. This emphasis on research and technology (R&T) in the fastener segment reflects a commitment to continuous innovation and improvement in aerospace fastening solutions.

3. Pioneering Aerospace Fastener Solutions

Companies like Skybolt have been driving innovations in aerospace fasteners, pioneering solutions that address the unique challenges of the aerospace industry. Its focus on developing cutting-edge fastener solutions has contributed to advancements in aerospace fastening technology.

4. Advanced Engineered Fastener Solutions

Monogram Aerospace Fasteners, a foremost designer, has introduced trademarked custom-engineered fastener solutions such as Visu-Lok, Composi-Lok, Radial-Lok, and OSI-Bolt. These unique solutions offer innovative fastening options for the aerospace industry, catering to the specific needs of commercial, manufacturing businesses, and military aircraft.

5. Lightweight and Strong Fasteners

Companies like Sky Climber Fasteners have launched a new generation of aerospace fasteners, focusing on innovations resulting in lighter and stronger designs. These advancements have contributed to the development of fasteners that meet the evolving requirements of modern aircraft construction, emphasizing both performance and weight considerations.

These innovations have been driven by the need for high-performance, lightweight, and durable fastening solutions to meet the evolving demands of modern aircraft construction.

Quick Recap

Aerospace fasteners play an essential role in aircraft construction by holding various parts of the aircraft together and enabling them to function properly. Various types of fasteners, such as bolts and screws, rivets, nuts, and washers, are used for various purposes in aerospace structures. Due to their high performance, state-of-the-art designs, and compact dimensions, aircraft fasteners are capturing the interest of numerous manufacturers.

As advancements continue, companies manufacturing aircraft fasteners are becoming increasingly innovative. Whether through advanced engineering solutions or the creation of lightweight and durable fasteners, these innovative solutions are redefining the landscape of aerospace manufacturing.