Buy Now

Industrial Hose Market

Industrial Hose Market Size, Share, Growth & Industry Analysis, By Material (Rubber, PVC, Silicone, Polyurethane, Others), By Media (Air, Water, Oil, Chemicals, Others), By End-Use (Agriculture, Oil & Gas, Construction, Mining, Chemical, Others), and Regional Analysis, 2024-2031

Pages: 120 | Base Year: 2023 | Release: July 2024 | Author: Swati J.

Industrial Hose Market Size

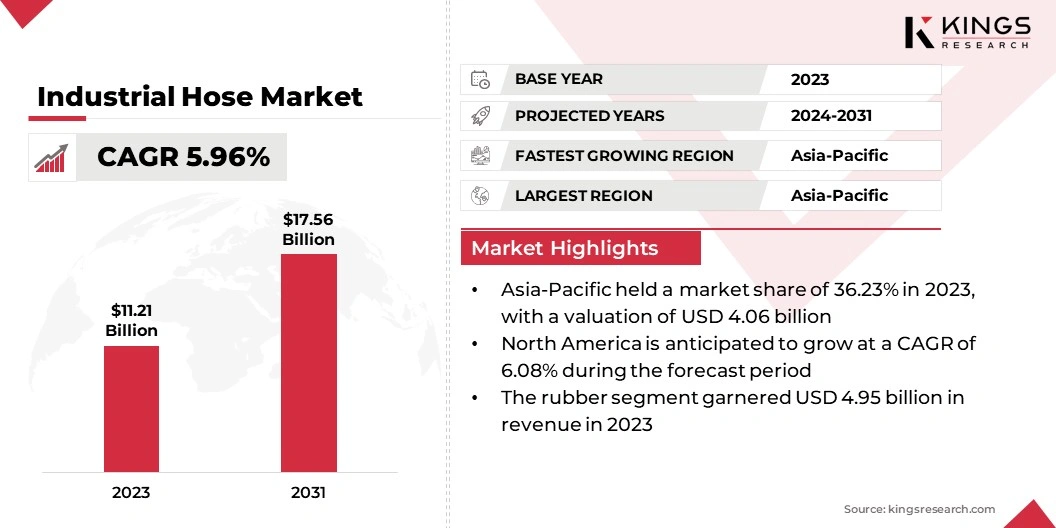

The global Industrial Hose Market size was valued at USD 11.21 billion in 2023 and is projected to grow from USD 11.71 billion in 2024 to USD 17.56 billion by 2031, exhibiting a CAGR of 5.96% during the forecast period. The market is growing rapidly due to increased industrialization, rapid urbanization, and ongoing technological advancements.

Key industries such as manufacturing, construction, mining, and food and beverages depend on durable and efficient hoses for fluid management. Innovations in materials such as thermoplastics enhance performance and meet stringent standards. The integration of smart technologies and the shift toward eco-friendly solutions are further boosting market expansion and increasing adoption across various sectors.

In the scope of work, the report includes solutions offered by companies such as Gates Corporation, Parker Hannifin Corp., Semperit AG Holding, Campbell Fittings, Inc., United Flexible, Continental AG, Eaton Corporation Plc., Polyhose India Pvt. Ltd., Trelleborg AB, RYCO Hydraulics, and others.

The industrial hose market is driven by the increasing demand for durable and flexible solutions across diverse sectors, including manufacturing, construction, and mining. Industrial hoses are essential for transporting fluids, gases, and solids in various applications, offering resilience against abrasion, chemicals, and extreme temperatures. Key market trends include advancements in hose materials and design to enhance performance and safety. The growing emphasis on automation and infrastructure development further propels market expansion.

- According to Invest India, the construction industry in India received significant foreign direct investment (FDI), totaling $33.91 billion from April 2000 to March 2024. During this period, 100% FDI in completed projects was permitted through the automatic route.

This policy allowed foreign investors to fully participate in the operations and management of townships, malls/, shopping complexes, and business constructions upon the completion of these projects.

An industrial hose is a flexible, reinforced tube designed for the transportation of various materials, including liquids, gases, and solids, in industrial settings. These hoses are constructed from a variety of materials such as rubber, thermoplastics, and metal to ensure durability and resistance to harsh conditions such as extreme temperatures, chemicals, and abrasion.

Industrial hoses are used in numerous applications across different industries, including manufacturing, construction, mining, agriculture, and food and beverages, providing reliable solutions for fluid transfer, material handling, and equipment operation.

Analyst’s Review

The industrial hose market is set to experience significant growth, fueled by increasing demand across various sectors and continuous technological advancements. Strategic collaborations and mergers are playing a crucial role in this expansion.

- For instance, in April 2023, Kurt Manufacturing finalized the acquisition of Bellatex Industries LLC, the owner of CARVESMART.

This strategic move bolstered Kurt Manufacturing's product portfolio and facilitated a targeted growth strategy aimed at expanding its footprint in the global market. The acquisition provided Kurt Manufacturing with enhanced capabilities and resources to meet growing market demands. This strategic move positions the company to capitalize on new opportunities and strengthen its competitive standing in the industry.

Key players in the market are integrating advanced technologies, expanding product portfolios through strategic mergers, and enhancing their global presence, which is contributing to market expansion. Streamlining operations and focusing on sustainable practices is likely to further strengthen their competitive edge and meet evolving customer demands effectively.

Industrial Hose Market Growth Factors

The growing industrialization and rapid urbanization worldwide are propelling the growth of the industrial hose market. In manufacturing, construction, and mining, the essential role of hoses in material conveyance, fluid management, and machinery operation is boosting demand.

Urban infrastructure projects further increase the need for efficient water and waste management systems, HVAC systems, and construction equipment, all of which rely on industrial hoses. This surge in demand, attributed to expanding industrial activities and urban development, is stimulating market growth, leading to advancements in hose technology and increased production to meet diverse industry needs.

- For instance, in September 2022, Kongsberg Automotive ASA (KA) consolidated its Fluid Transfer Systems (FTS) and Couplings business units into a unified entity named Flow Control Systems.

KA's FTS division, recognized for providing PTFE hoses and assemblies to industrial and automotive sectors, merged with its couplings unit, which supplies compressed air couplings to the global commercial vehicle market. This merger enables KA to capitalize on synergies between the divisions, streamline operations, reduce costs, and enhance its product portfolio.

The fluctuating prices of raw materials and stringent regulatory requirements present significant hurdles to the development of the market. Fluctuations in raw material costs may impact manufacturing budgets and pricing strategies, potentially leading to a reduction of profit margins. Moreover, navigating diverse regulatory landscapes requires substantial resources and compliance efforts, resulting in delays in product launches and market entry.

However, key players in the industrial hose market are increasingly investing in research and development to innovate new materials and manufacturing processes that reduce dependency on volatile raw material prices. They are further enhancing their global supply chains and collaborating with regulatory bodies to ensure compliance, thereby maintaining operational efficiency and competitive pricing in diverse markets. These strategic initiatives enable them to navigate market challenges effectively while sustaining growth and profitability.

Industrial Hose Market Trends

Innovations in materials and manufacturing processes are revolutionizing the market, leading to the production of more durable, flexible, and efficient products. The use of advanced materials such as thermoplastics and rubber compounds has significantly enhanced hose performance, making them more resistant to chemicals, extreme temperatures, and abrasion.

These improvements increase the lifespan and reliability of industrial hoses, thereby reducing maintenance costs and minimizing downtime for industries. Sectors such as manufacturing, construction, and chemical processing are increasingly adopting these high-performance hoses, thereby aiding market growth and pronoting further advancements in hose technology and materials.

The rapid growth of the food and beverages industry is contributing significantly to the expansion of the industrial hose market. Industrial hoses have become crucial in this sector, offering reliable, hygienic, and efficient solutions for fluid transfer during production. They are widely used to handle fluids like milk, juice, beer, wine, water, and other ingredients.

These hoses are designed to comply with stringent regulatory standards, including those set by the FDA and NSF, thereby ensuring both safety and quality. The increasing demand for hygienic and efficient fluid handling solutions in the expanding food and beverages industry is fostering the adoption of industrial hoses, thereby fueling market growth.

Segmentation Analysis

The global market is segmented based on material, media, end-use, and geography.

By Material

Based on material, the industrial hose market is categorized into rubber, PVC, silicone, polyurethane, and others. The rubber segment garnered the highest revenue of USD 4.95 billion in 2023, due to its crucial characteristics, including its flexibility, durability, and robust resistance to abrasion and chemicals. It serves a wide range of industries, including manufacturing, construction, mining, and automotive by providing essential solutions for fluid transfer applications.

Ongoing innovations in rubber formulations and manufacturing processes continually enhance performance, ensuring compliance with stringent industry standards and meeting evolving customer needs. With its versatility and reliability, the rubber segment is anticipated to grow substantially, thereby supporting various industrial operations globally and boosting demand across diverse sectors.

By Media

Based on media, the market is divided into air, water, oil, chemicals, and others. The air segment captured the largest industrial hose market share of 30.70% in 2023. Industrial hoses are increasingly used in applications such as pneumatic tools, air compressors, HVAC systems, and pneumatic conveying systems. Key products include flexible hoses that ensure efficient air flow, durability, and resistance to abrasion and weathering.

The increasing adoption of pneumatic technologies in industrial automation drives demand for reliable air hoses. Innovations in materials and manufacturing processes, including lightweight and flexible designs, contribute to enhanced performance and operational efficiency. This growth is further bolstered by expanding industrial activities globally, emphasizing the critical role of air hoses in enhancing productivity and operational efficiency across diverse applications.

By End-Use

Based on end-use, the market is categorized into agriculture, oil & gas, construction, mining, chemical, and others. The oil & gas segment is expected to garner the highest revenue of USD 5.44 billion by 2031. This growth is propelled by the growing utilization of industrial hoses in oil & gas sector, particularly in critical applications such as hydraulic fracturing, oil drilling, and refining processes. These hoses are required to withstand extreme conditions, including high pressures, corrosive fluids, and wide temperature ranges, highlighting the need for robust materials such as synthetic rubber and advanced thermoplastics.

As global energy demands rise, the demand for efficient fluid transfer solutions also grows, thereby propelling continuous innovation and increased investment in durable hose technologies. The growing demand for industrial hoses in oil and gas operations to ensure operational reliability, safety, and regulatory compliance is further aiding segmental growth.

Industrial Hose Market Regional Analysis

Based on region, the global market is classified into North America, Europe, Asia-Pacific, MEA, and Latin America.

Asia-Pacific industrial hose market share stood around 36.23% in 2023 in the global market, with a valuation of USD 4.06 billion. This growth is largely attributed to robust industrialization across sectors such as manufacturing, construction, automotive, and oil & gas. Technological advancements in hose materials and manufacturing processes, coupled with stringent regulatory standards such as FDA and NSF compliance, bolster domestic market growth.

The region's diverse industrial applications, including fluid transfer, material handling, and equipment operation, boost the demand for specialized hose solutions. Infrastructure development projects further support regional market expansion. Additionally as the sales of hybrid and electric vehicles increase in the Asia Pacific region, the demand for high-performance and lightweight hoses, primarily made of polymers, is likely to grow in line with the production of electric vehicles over the forecast period.

- For instance, in May 2022, Toyota Group revealed plans to invest approximately USD 624 million in India to support the manufacturing of electric vehicle components.

This initiative aligns with the Indian government's efforts to promote electric vehicles (EVs) through various initiatives aimed at reducing emissions and fostering e-mobility, thereby augmenting regional market growth.

North America is anticipated to witness significant growth at a CAGR of 6.08% over the forecast period. Technological advancements in hose materials and manufacturing processes, coupled with stringent regulatory standards such as FDA and NSF compliance, bolster domestic market growth. The region's diverse industrial applications, including fluid transfer, material handling, and equipment operation, continue to fuel demand for specialized hose solutions.

Infrastructure development projects further contribute to regional market expansion. Innovations in smart technologies and eco-friendly materials underscore North America's commitment to enhancing operational efficiency and sustainability within its industrial operations, positioning it as a key market for industrial hoses.

Competitive Landscape

The global industrial hose market report will provide valuable insight with an emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions.

Companies are implementing impactful strategic initiatives, such as expanding services, investing in research and development (R&D), establishing new service delivery centers, and optimizing their service delivery processes, which are likely to create new opportunities for market growth.

List of Key Companies in Industrial Hose Market

- Gates Corporation

- Parker Hannifin Corp.

- Semperit AG Holding

- Campbell Fittings, Inc.

- United Flexible

- Continental AG

- Eaton Corporation Plc.

- Polyhose India Pvt. Ltd.

- Trelleborg AB

- RYCO Hydraulics

Key Industry Development

- July 2022 (Geographical expansion): Continental AG's industrial segment ContiTech announced a major restructuring of its hose sites in Germany. This decision was made in response to an oversupply of rubber hoses for combustion engines, which has resulted from the ongoing transition in the automotive industry. Continental AG aimed to optimize operations and adjust to changing market dynamics by realigning its production capabilities. This restructuring reflected the industry's shift toward electric vehicles and sustainable mobility solutions, prompting ContiTech to strategically reposition itself to adapt to evolving market demands and advancements in automotive engineering.

The global industrial hose market is segmented as:

By Material

- Rubber

- PVC

- Silicone

- Polyurethane

- Others

By Media

- Air

- Water

- Oil

- Chemicals

- Others

By End-Use

- Agriculture

- Oil & Gas

- Construction

- Mining

- Chemical

- Others

By Region

- North America

- U.S.

- Canada

- Mexico

- Europe

- France

- U.K.

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America