buyNow

Conveyor Belt Market

Conveyor Belt Market Size, Share, Growth & Industry Analysis, By Type (Flat Conveyor Belts, Modular Conveyor Belts, Specialty Conveyor Belts, Others), By Material (Rubber Conveyor Belts, PVC Conveyor Belts, Others), By End-User Industry, By Technology, and Regional Analysis, 2024-2031

pages: 120 | baseYear: 2023 | release: December 2024 | author: Versha V.

Conveyor Belt Market Size

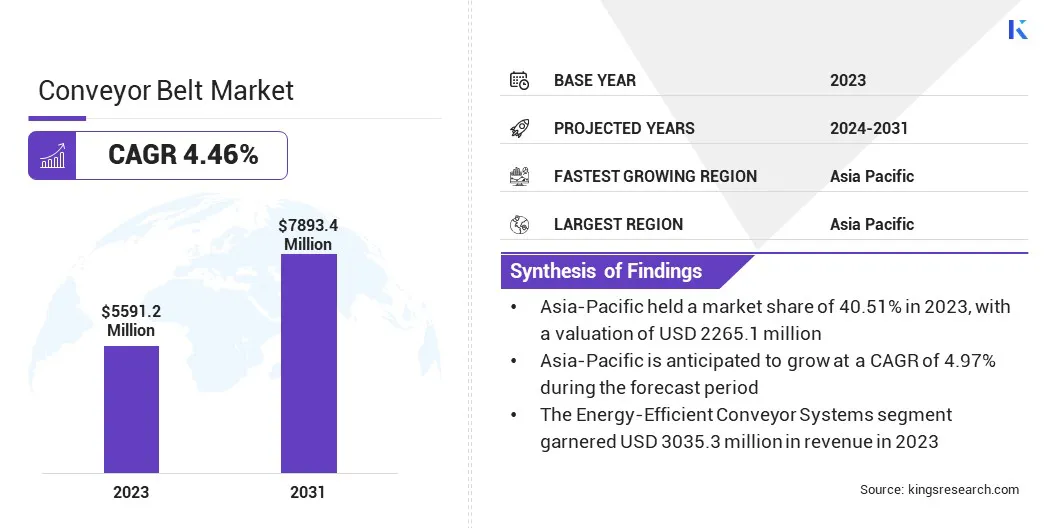

The global Conveyor Belt Market size was valued at USD 5591.2 million in 2023 and is projected to grow from USD 5814.0 million in 2024 to USD 7893.4 million by 2031, exhibiting a CAGR of 4.46% during the forecast period.

The market is growing due to its use and growing demand in various industrial applications, including automation, manufacturing, logistics, mining, food processing, and automotive. This product is witnessing higher adoption due to the increasing demand for energy-efficient, smart, and sustainable systems to enhance operational efficiency and productivity.

In the scope of work, the report includes products offered by companies such as Bridgestone Corporation, Fenner Dunlop B.V., Semperit AG Holding, Elcon Elastomers Pvt. Ltd., Bando Chemical Industries, LTD, Ammeraal Beltech, TGW LOGISTICS GROUP GMBH, THE YOKOHAMA RUBBER CO., LTD., Somi Conveyor Beltings Ltd., Shriram Beltings, and others.

Conveyor belt is a critical component in numerous industries, offering assistance in various processes such as material handling, transport, and automation. Due to their ability to facilitate continuous movement of goods, conveyor belts are extensively used in manufacturing, logistics, mining, food processing, and other sectors.

Conveyor belts enhance operational efficiency, reduce manual labor, and ensure streamlined processes. The conveyor belt market offers a diverse range of products, from heavy-duty belts for industrial applications to specialized belts for food-grade and precision tasks, demonstrating its versatility across applications and industries.

- In October 2024, Siemens AG agreed to sell its Siemens Logistics business to Vanderlande, a leader in logistics automation for warehousing, airports, and parcels. This acquisition highlights the critical role of conveyor belts in enhancing operational efficiency, reducing manual labor, and streamlining processes across logistics and manufacturing industries.

The conveyor belt industry is involved in the production, distribution, and use of conveyor systems for transporting materials and goods within various processes. Conveyor belts are integral to automation and material handling, facilitating the efficient movement of products in manufacturing, logistics, mining, food processing, and many other sectors.

Conveyor belts are continuous loops of flexible material, designed to move items from one location to another, often over long distances or in challenging environments. The conveyor market covers a wide range of belt types, each suited to specific applications, such as heavy-duty industrial belts or specialized belts for food-grade and high-precision tasks. Demand for increased automation, productivity, and operational efficiency drives the market.

Analyst’s Review

Analyst’s Review

The conveyor belt market is witnessing a strategic shift toward automation, driven by the need for efficiency and precision among manufacturers. Companies are also integrating conveyor systems with robotics and AI to streamline production and logistics. This approach supports smart manufacturing and infrastructure.

As industries evolve, the focus will shift to scalable, energy-efficient systems that reduce manual labor and improve throughput. The convergence of automation and conveyor technology will likely redefine operational capabilities across mining, automotive, pharmaceuticals, and e-commerce operations.

- In September 2024, alwaysAI and Becker Mining Systems announced a strategic partnership to enhance the mining industry. They plan to develop advanced computer vision applications for real-time conveyor belt monitoring, detecting wear and damage early, ensuring PPE compliance, and automating processes to boost productivity, safety, and operational efficiency.

Conveyor Belt Market Growth Factors

The rapid growth of e-commerce has significantly driven the demand for efficient logistics and warehousing solutions. Conveyor systems play a crucial role in modern, automated warehouses, particularly in e-commerce industry, where they streamline sorting, packaging, and transportation.

Since consumers seek faster delivery, conveyor belts help enhance workflow efficiency, reduce bottlenecks, and speed up order fulfillment. This adoption of automated conveyor systems is essential for handling high-volume shipments, improving operational efficiency, and meeting the demand for quicker delivery times in the competitive e-commerce landscape.

- According to the International Trade Administration, rapid growth of the e-commerce market, expanding at a rate of 14.4% with leading segments such as consumer electronics, fashion, and food, directly impacts the conveyor belt market. The increasing demand for efficient logistics and warehousing solutions drives the need for automated conveyor systems to streamline sorting, packaging, and transportation.

A major challenge in the conveyor belt market is the need for regular maintenance to prevent breakdowns, which can impact operational efficiency. To address this, companies can implement predictive maintenance solutions using sensors and real-time data analytics to monitor the health of conveyor systems.

This approach helps identify potential issues before they cause significant downtime, minimizing disruptions and extending equipment lifespan. Additionally, regular training for operators and technicians can enhance preventive maintenance efforts.

- In February 2024, Siemens introduced generative AI functionality into its Senseye Predictive Maintenance solution. This enhancement makes predictive maintenance more intuitive and conversational, improving the speed and efficiency of machine health monitoring. By using sensors and real-time analytics, companies can proactively identify issues and minimize downtime in conveyor systems.

Conveyor Belt Industry Trends

A significant trend in the conveyor belt market is the growing demand for smart conveyor systems, driven by the integration of Internet of Things (IoT) sensors. These systems enable real-time monitoring, providing valuable insights into system performance, and offer predictive maintenance capabilities.

By leveraging data analytics, smart conveyors can detect potential issues before they lead to breakdowns, allowing for timely interventions. This proactive approach minimizes downtime, reduces repair costs, and ensures the continuous and efficient operation of conveyor systems across industries.

- In November 2024, Bosch Rexroth introduced the VarioFlow belt conveyor, expanding its VarioFlow conveyor system. This smart system features a fine-meshed surface, ideal for handling delicate and unstable products. Its modular, customizable design and quick installation capabilities help streamline operations in FMCG, pharmaceuticals, and healthcare, enhancing efficiency while reducing engineering time.

Another key trend in the conveyor belt market is the shift toward energy-efficient and sustainable solutions. With increasing focus on sustainability, manufacturers are developing belts that consume less energy, helping companies minimize their carbon footprint and reduce operational costs. These eco-friendly innovations will be crucial in industries aiming to meet environmental goals while enhancing operational efficiency.

By prioritizing energy efficiency, conveyor systems are contributing to environmental sustainability and long-term cost savings at par with global efforts to adopt greener technologies in industrial operations.

- In October 2023, LKAB awarded ABB a contract to install Gearless Conveyor Drives (GCDs) at its Malmberget mine in Sweden. Upgrades to this technology will reduce energy consumption by 6-10%. This shift toward sustainable solutions can lower operational costs and environmental impact.

Segmentation Analysis

The global market has been segmented based on type, material, end-user industry, technology, and geography.

By Type

Based on type, the market has been segmented into flat conveyor belts, modular conveyor belts, specialty conveyor belts, and others. The flat conveyor belts segment led the conveyor belt market in 2023, reaching USD 2040.1 million.

The growing demand for flat conveyor belts is significantly driving the expansion of the market. Flat conveyor belts are known for their versatility, efficiency, and ability to handle a wide range of products from manufacturing to food processing.

These belts are ideal for moving items on flat surfaces and can transport products with uniform or irregular shapes. This makes them essential for industries requiring high-volume and continuous material handling. Their design allows smooth, stable movement, reducing friction and minimizing wear. Their efficiency, cost-effectiveness, and ease of maintenance, position flat conveyor belts as a key segment in market growth.

By Material

Based on material, the market has been classified into rubber conveyor belts, PVC conveyor belts, polyurethane (PU) conveyor belts, and others. The rubber conveyor belts segment secured the largest revenue share of 41.87% in 2023.

Rubber is extensively used in conveyor belts due to its durability, flexibility, and resistance to wear, which makes it ideal for handling heavy loads. Its ability to withstand harsh conditions, such as extreme temperatures, chemicals, and moisture, enhances the longevity of the conveyor system. Rubber conveyor belts offer superior traction, ensuring smooth material handling across various industries, including mining, automotive, and food processing.

Additionally, their noise reduction properties and ease of maintenance contribute to their widespread adoption. The material’s versatility and performance in demanding applications are key drivers of the segment’s significant market expansion.

By End-User Industry

Based on end-user industry, the market has been classified into automotive industry, mining industry, food & beverage industry, logistics & warehousing, and others. The logistics & warehousing segment is poised for significant growth at a CAGR of 5.65% over the forecast period.

Conveyor belts are extensively used in logistics and warehousing due to their ability to efficiently transport goods across long distances, reducing manual labor and increasing operational speed. In modern warehouses, conveyor belts can streamline sorting, packaging, and transportation, ensuring faster order fulfillment and minimizing bottlenecks.

They are crucial in handling a wide range of materials, from small packages to heavy items, with precision and consistency. Their integration with robotics and advanced technologies, is expected to enhance their effectiveness by enabling real-time monitoring. This makes conveyor belts a valuable tool for optimizing logistics operations and improving overall efficiency.

Conveyor Belt Market Regional Analysis

Based on region, the global market has been classified into North America, Europe, Asia-Pacific, MEA, and Latin America.

The Asia-Pacific conveyor belt market share stood at 40.51% in 2023 in the global market, with a valuation of USD 2265.1 million. Asia Pacific is a dominant region in the market due to its rapid industrialization, robust manufacturing sector, and expanding e-commerce industry. China, India, and Japan are major hubs for manufacturing, mining, and logistics, which is driving the demand for conveyor systems in these regions.

The Asia-Pacific conveyor belt market share stood at 40.51% in 2023 in the global market, with a valuation of USD 2265.1 million. Asia Pacific is a dominant region in the market due to its rapid industrialization, robust manufacturing sector, and expanding e-commerce industry. China, India, and Japan are major hubs for manufacturing, mining, and logistics, which is driving the demand for conveyor systems in these regions.

Additionally, APAC’s growing focus on automation, efficiency, and cost reduction fuels the market growth. The rise of major logistics players and the increasing adoption of automated systems in warehouses and fulfillment centers contribute significantly to the region's dominance. Asia Pacific's large-scale infrastructure projects and industrial developments are expected to continue driving the conveyor market expansion.

North America is expected to witness significant growth over the forecast period at a CAGR of 4.87%. North America is a fast-growing region in the conveyor belt market due to its advanced technological infrastructure, strong manufacturing base, and significant investments in automation. The rise of e-commerce giants, increased demand for efficient logistics, and the push for smarter, energy-efficient conveyor systems are key market drivers.

Adopting technologies, including robotics and artificial intelligence, accelerate automation in warehouses and manufacturing units. Additionally, the need for improved supply chain efficiency and reduced operational costs across various industries, such as automotive and food & beverage, further boosts the growth of the conveyor market in North America.

Competitive Landscape

The global conveyor belt market report provides valuable insights emphasizing the industry's fragmented nature. Prominent players focus on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions.

Strategic initiatives, including investments in R&D activities, establishment of new manufacturing facilities, and supply chain optimization, could create new opportunities for market growth.

List of Key Companies in the Conveyor Belt Market

- Bridgestone Corporation

- Fenner Dunlop B.V.

- Semperit AG Holding

- Elcon Elastomers Pvt. Ltd.

- Bando Chemical Industries, LTD

- Ammeraal Beltech

- TGW LOGISTICS GROUP GMBH

- THE YOKOHAMA RUBBER CO., LTD.

- Somi Conveyor Beltings Ltd.

- Shriram Beltings

Key Industry Developments

- April 2024 (Partnership): Walmart announced installation of a Swisslog automated storage and retrieval solution (ASRS) at its new milk processing facility in Robinson, TX. This solution, scheduled to open in 2026, will include Vectura cranes, a pallet conveyor system, and SynQ software to optimize material flow and uptime. This will make Walmart’s supply chain more resilient, enhance its inventory management, and reduce downtime across its facilities throughout the South.

- January 2023 (Acquisition): Belt Power, LLC, a prominent distributor and fabricator of belting and components for lightweight conveyor systems, acquired Dunham Rubber & Belting Corporation. Dunham offers a wide range of lightweight belting products and services across Indiana. The acquisition strengthened Belt Power's reach and enhanced its fabrication capabilities, enabling it to provide value-added solutions to food processing, material handling, pharmaceuticals, and general industrial markets.

The global conveyor belt market has been segmented:

By Type

- Flat Conveyor Belts

- Modular Conveyor Belts

- Specialty Conveyor Belts

- Others

By Material

- Rubber Conveyor Belts

- Natural Rubber Belts

- Synthetic Rubber Belts

- PVC Conveyor Belts

- Standard PVC Belts

- Antistatic PVC Belts

- Polyurethane (PU) Conveyor Belts

- Food-Grade PU Belts

- Heavy-Duty PU Belts

- Others

By End-User Industry

- Automotive Industry

- Mining Industry

- Food & Beverage Industry

- Logistics & Warehousing

- Others

By Technology

- Smart Conveyor Belts

- IoT-Enabled Conveyor Belts

- Automated Conveyor Belts

- Energy-Efficient Conveyor Systems

- Low-Energy Consumption Belts

- Regenerative Conveyor Systems

By Region

- North America

- U.S.

- Canada

- Mexico

- Europe

- France

- UK

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America